Reinforced sealing structure for working water cavity of reverse osmosis booster pump

A sealing structure, booster pump technology, applied in pumps with flexible working elements, parts of pumping devices for elastic fluids, pumps, etc., can solve insufficient compression, leakage of structural sealing parts, sealing parts c Leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

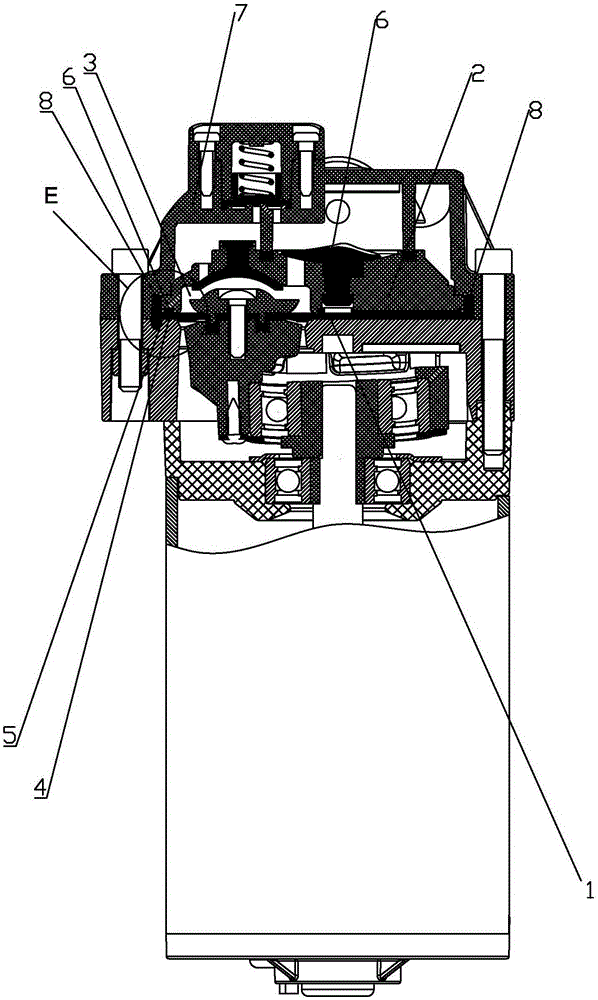

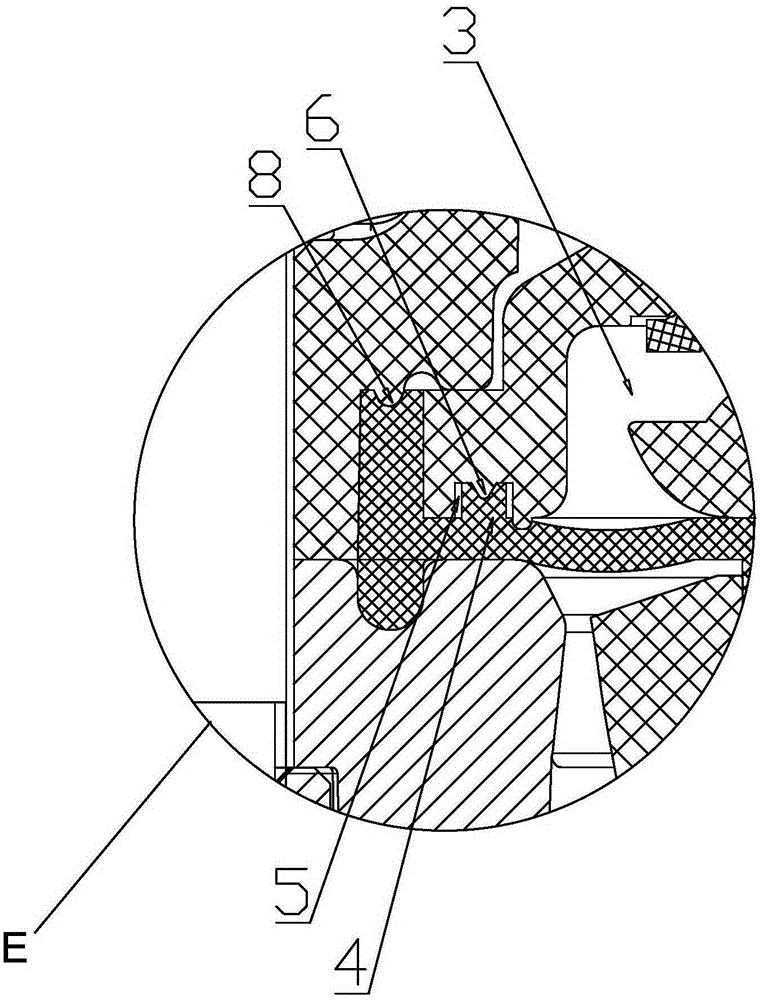

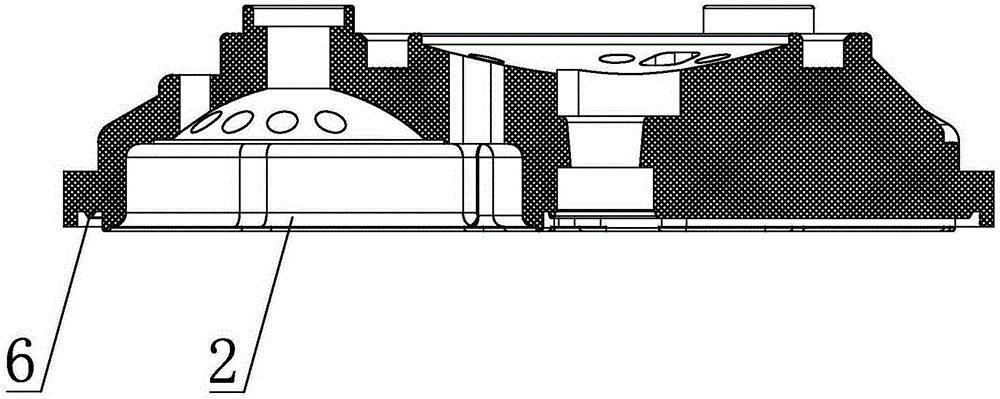

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0029] As shown in the figure, a reinforced sealing structure for the working water chamber of a reverse osmosis booster pump includes a diaphragm 1 and a diaphragm valve cover 2 covered on the diaphragm 1. There are three parts on the diaphragm 1 and the diaphragm valve cover 2. 3 independent chambers. Open the chamber 3, such as the three chamber regions 1-3 uniformly distributed on the diaphragm 1 and the three chamber regions 2-3 uniformly distributed on the diaphragm valve cover 2. A protruding ring 4 is provided around each chamber on the diaphragm 1, and a groove 5 that cooperates with each protruding ring 4 is provided at the bottom of the diaphragm valve cover 2 to keep each chamber sealed. The cooperation of the groove 5 forms a heavy seal in each chamber. In addition, a first protruding structure 6 is provided in the middle of the groove 5 of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com