Split type vibration and noise reduction air pump

A kind of vibration reduction and noise reduction, split technology, applied in the direction of variable volume pump parts, liquid variable volume machinery, pumps, etc., can solve the problems of large vibration and noise, inconvenient installation and disassembly, and disadvantages, to achieve low vibration noise, Easy to maintain, easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

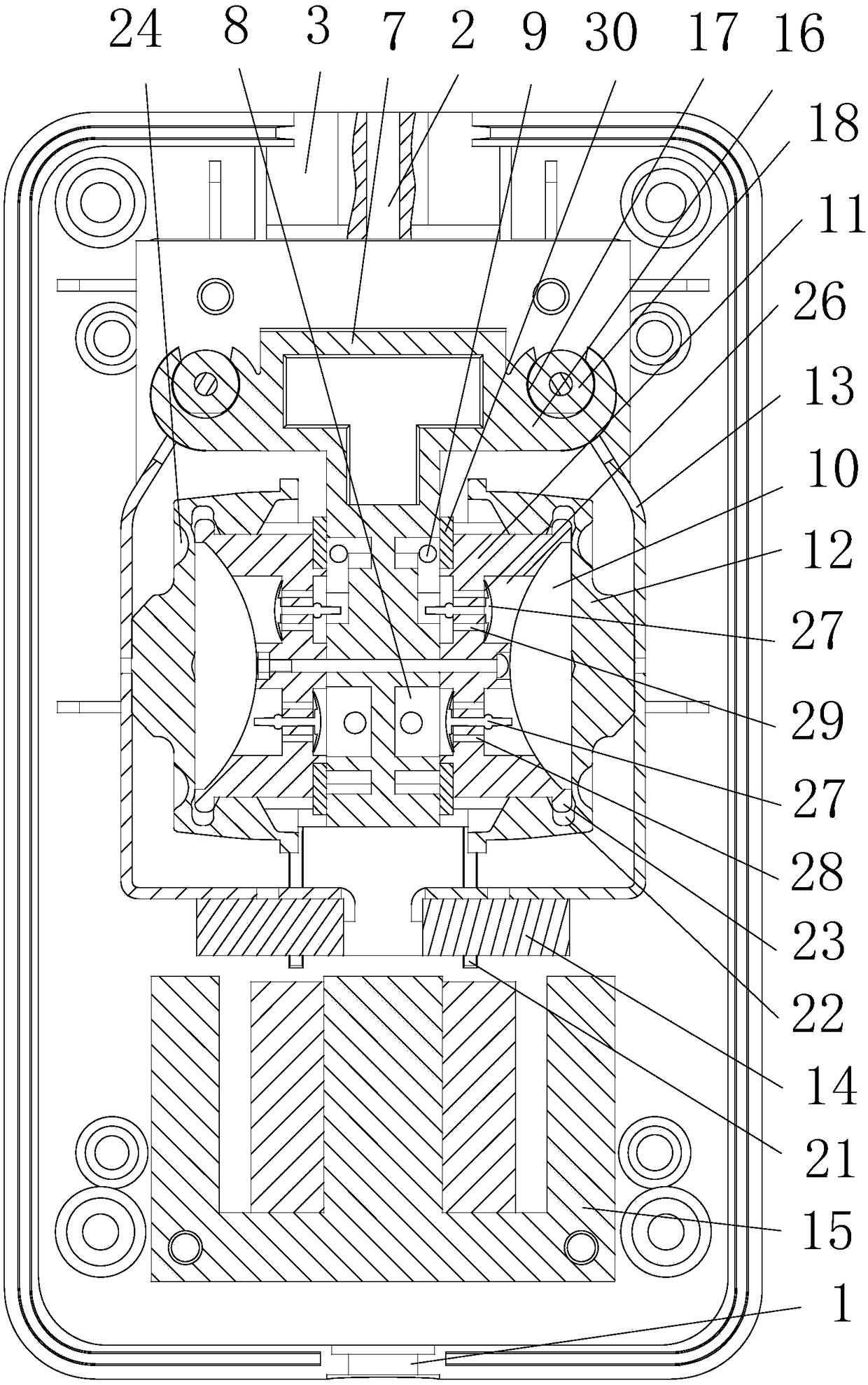

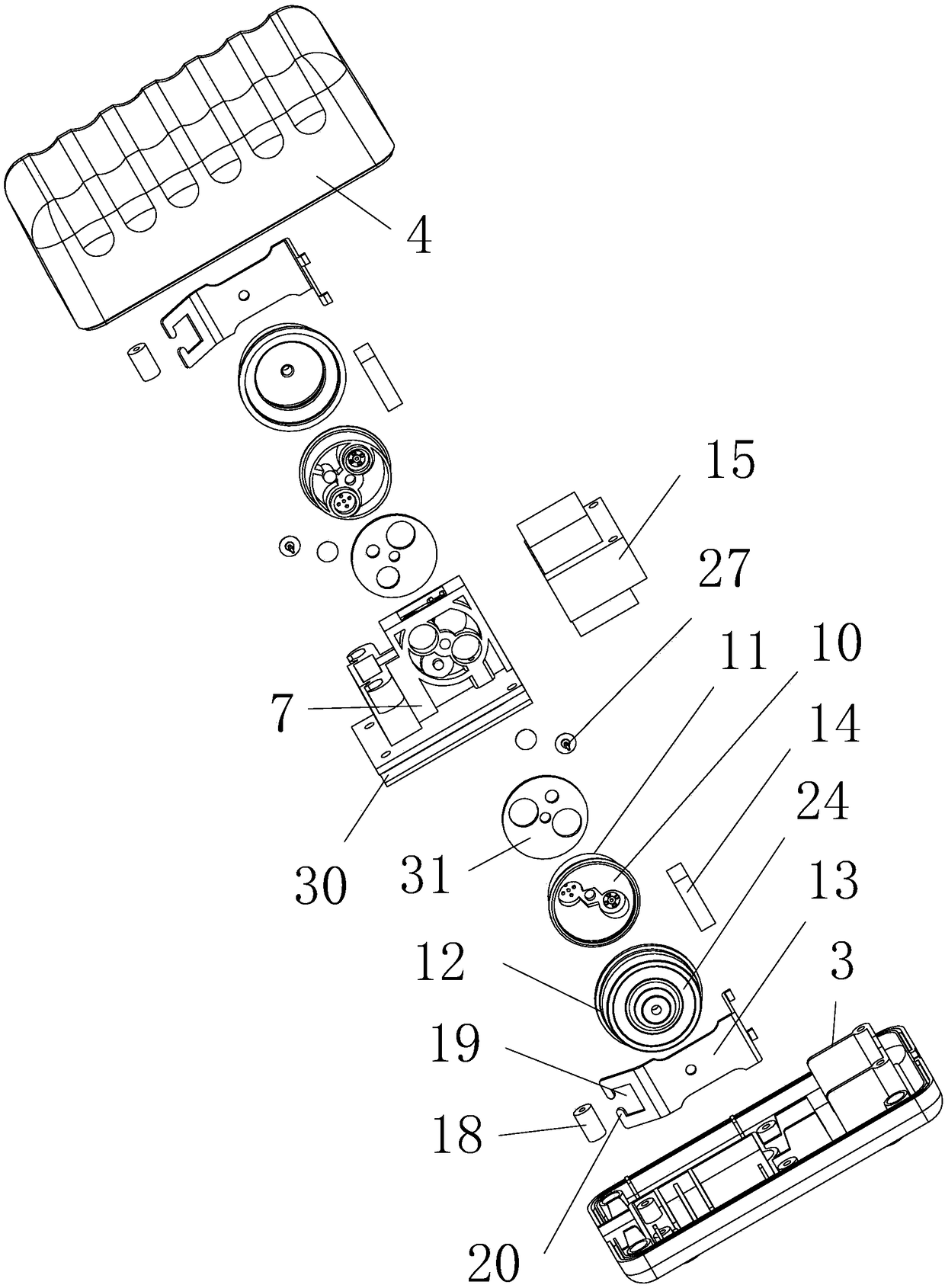

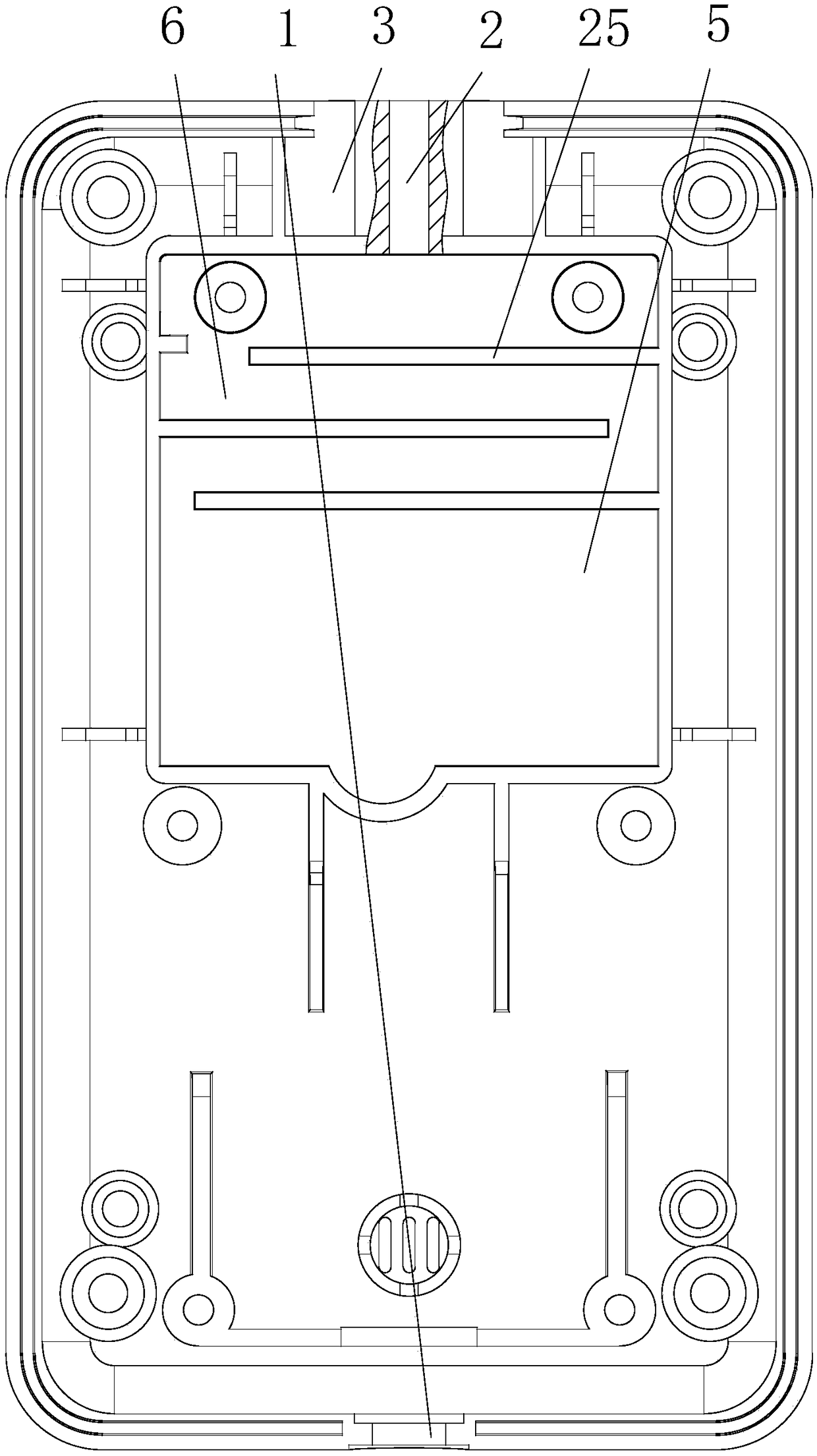

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] as attached figure 1 To attach Figure 5 Shown: a split-type vibration-reducing and noise-reducing air pump, including: a housing base 3 provided with an air inlet 1 and an air outlet 2, a housing cover 4 screwed to the housing base 3, and a vibration-damping valve provided at the upper end of the housing base 3 The noise reduction chamber 5, the reciprocating vibration reduction and noise reduction air passage 6 located at the rear side of the vibration reduction and noise reduction chamber 5 and communicated with the air outlet 2, blocks the vibration reduction and noise reduction chamber 5 and the reciprocating vibration and noise reduction air passage 6. The pump body 7 at the upper end and screwed with the shell base 3, several exhaust devices; The air outlet channel 9 connected to the noise chamber 5 is provided with an air chamber 10 and an air chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com