Semi-contact graphite sealing device

A semi-contact, graphite technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high sealing surface machining accuracy, large contact friction of sealing surface, short sealing life, etc., to achieve high working stability, The effect of enhancing the sealing effect and prolonging the sealing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

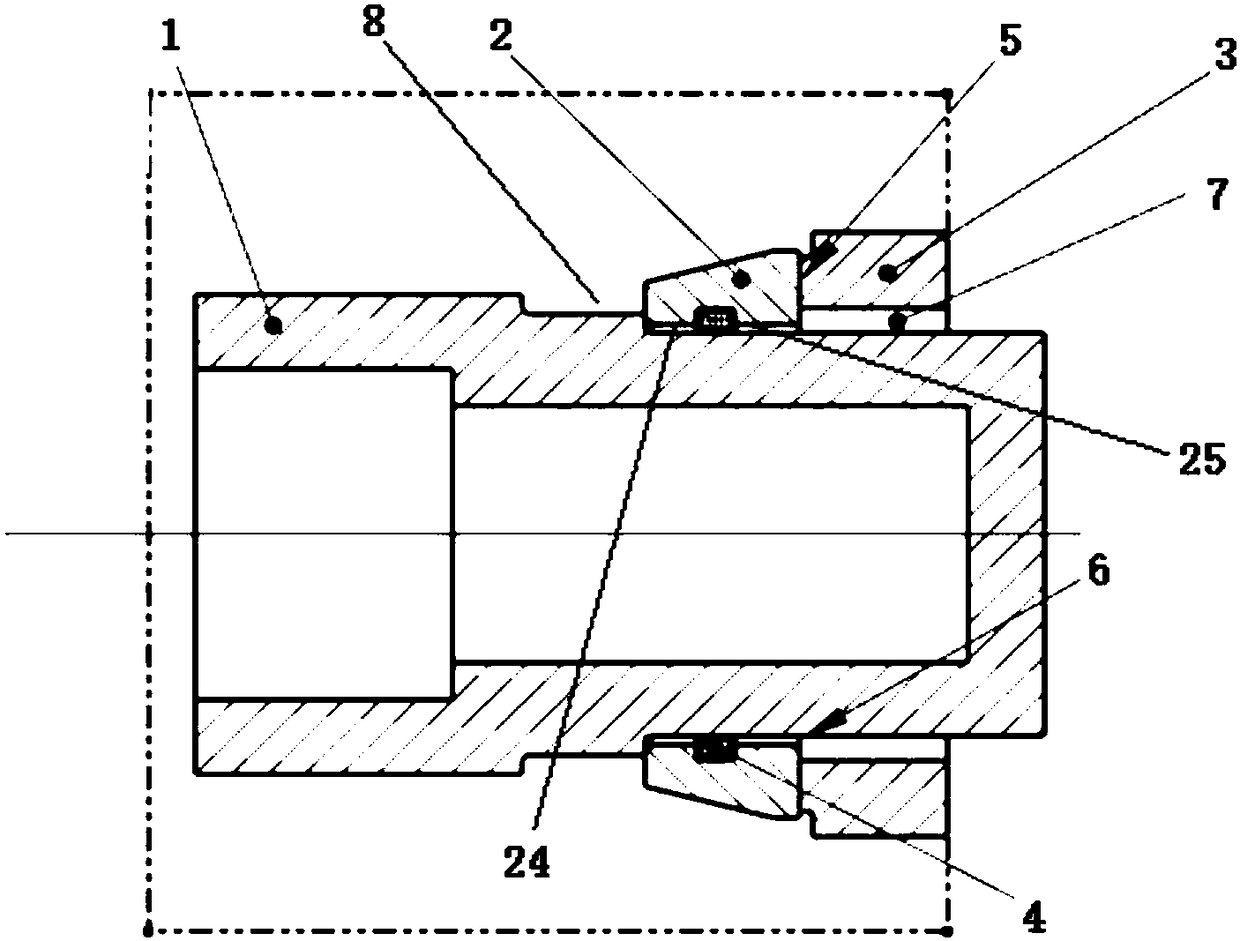

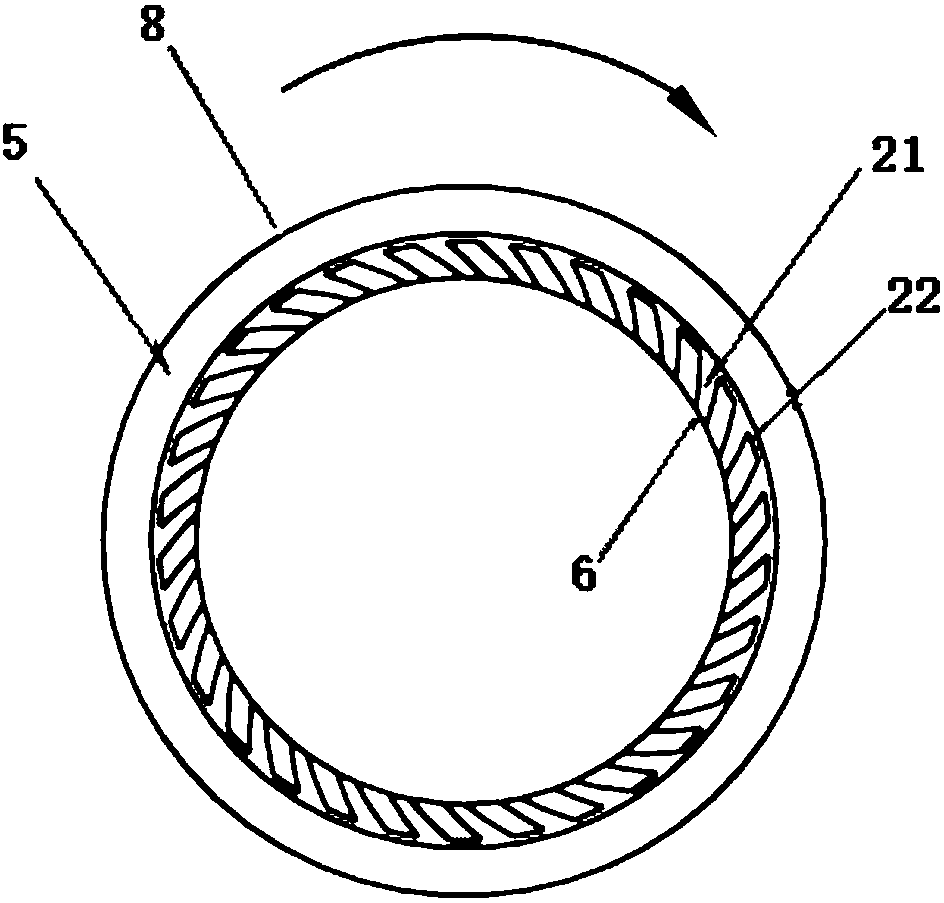

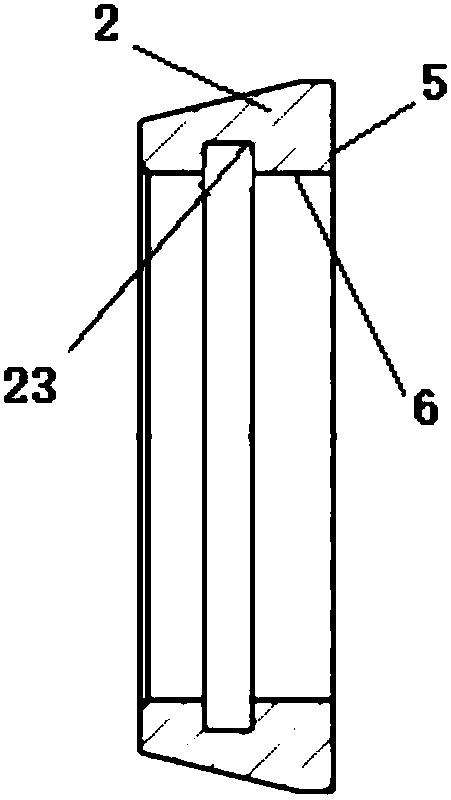

[0016] Example 1 as Figure 1 to Figure 3 As shown, the semi-contact graphite sealing device of this embodiment includes a static graphite ring 3 and a frictional dynamic ring 2 rotating with the rotating shaft 1, the inner ring surface 6 of the frictional dynamic ring 2 is in clearance fit with the rotating shaft 1, and the frictional dynamic ring 2 The inner ring surface 6 of the inner ring surface 6 is provided with a rubber ring groove 23 along the circumferential direction, and an elastically deformable sealing rubber ring 4 is arranged in the rubber ring ring groove 23. The sealing rubber ring 4 and the rotating shaft 1 have an interference fit, on the one hand, it plays a transmission role, The rotating shaft 1 drives the friction moving ring 2 to rotate at a high speed, and on the other hand acts as a seal to prevent the lubricating oil in the lubricating oil chamber 8 from leaking from the matching gap between the friction moving ring 2 and the rotating shaft 1; the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com