A water meter detection booster system and method

A pressurization system and water meter technology, applied in the direction of measuring fluid pressure, measuring devices, water conservation, etc., can solve the problems of no effective use of pressure, inability to realize water meter detection, poor pressurization and pressure maintaining effects, etc. Compression effects, improved sustained stability, and improved accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

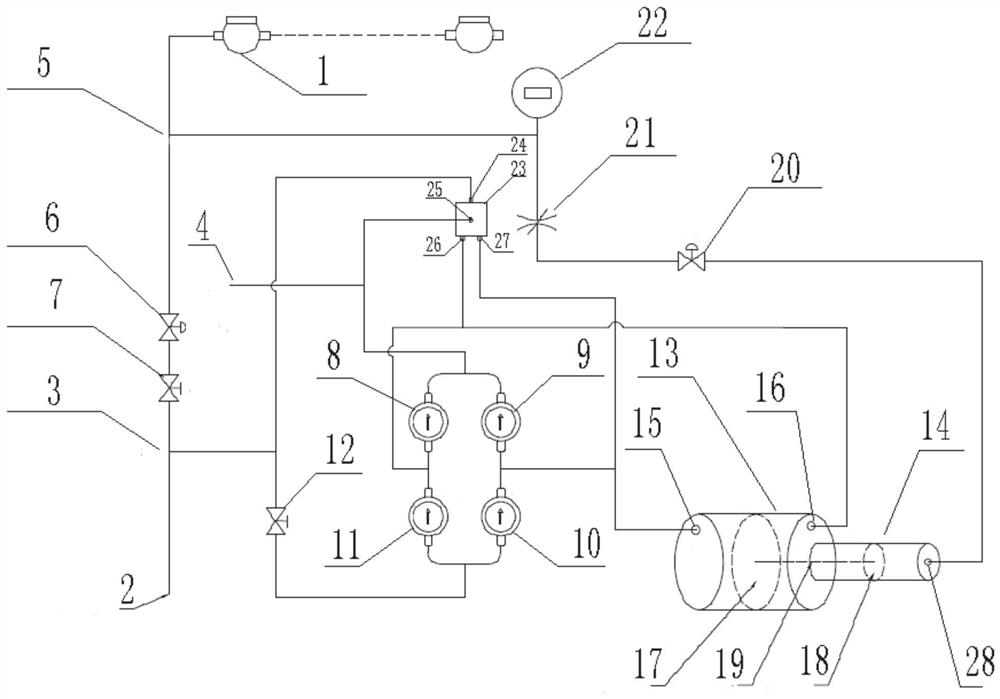

[0051]like figure 1 As shown, Embodiment 1 of the present disclosure provides a water meter detection booster system, which adopts a manual booster method, including a booster cylinder and a three-position four-way manual rotary valve 23, and the three-position four-way manual rotary valve 23 includes a third A port 24, a second port 25, a third port 26 and a fourth port 27, the first port is connected to the system water inlet port 3 through a pipeline, the second port is connected to the drain port through a pipeline, and the third port is connected to the pressure relief The ports are in communication, and the fourth port is in communication with the boosting port.

[0052] The booster cylinder includes a first cylinder block 13 and a second cylinder block 14 in communication, and the inner diameter of the second cylinder block 14 is smaller than that of the first cylinder block 13. The water outlet port of the second cylinder block 14 is connected to the water inlet port o...

Embodiment 2

[0068] like figure 1 As shown, Embodiment 2 of the present disclosure provides a water meter detection and pressurization system, which adopts an automatic pressing method, includes various structures in Embodiment 1, and also includes a first solenoid valve 8, The second solenoid valve 9, the third solenoid valve 10, the fourth solenoid valve 11;

[0069] The pipeline between the first solenoid valve and the second solenoid valve is communicated with the drain port 4, the pipeline between the second solenoid valve and the third solenoid valve is communicated with the boosting port 15, and the third solenoid valve and the fourth solenoid valve are connected The pipeline between them is communicated with the system water inlet port 3 , and the pipeline between the first solenoid valve and the fourth solenoid valve is communicated with the pressure relief port 16 .

[0070] The first solenoid valve and the third solenoid valve are connected in parallel to the first control circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com