Ratchet wheel rack inerter based on speed reducer

A ratchet gear and reducer technology, applied in the field of structural engineering, can solve problems such as vibration control of inerters staying in vehicles, and achieve the effects of solving unfavorable driving problems of gears, reducing resonance response, and large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

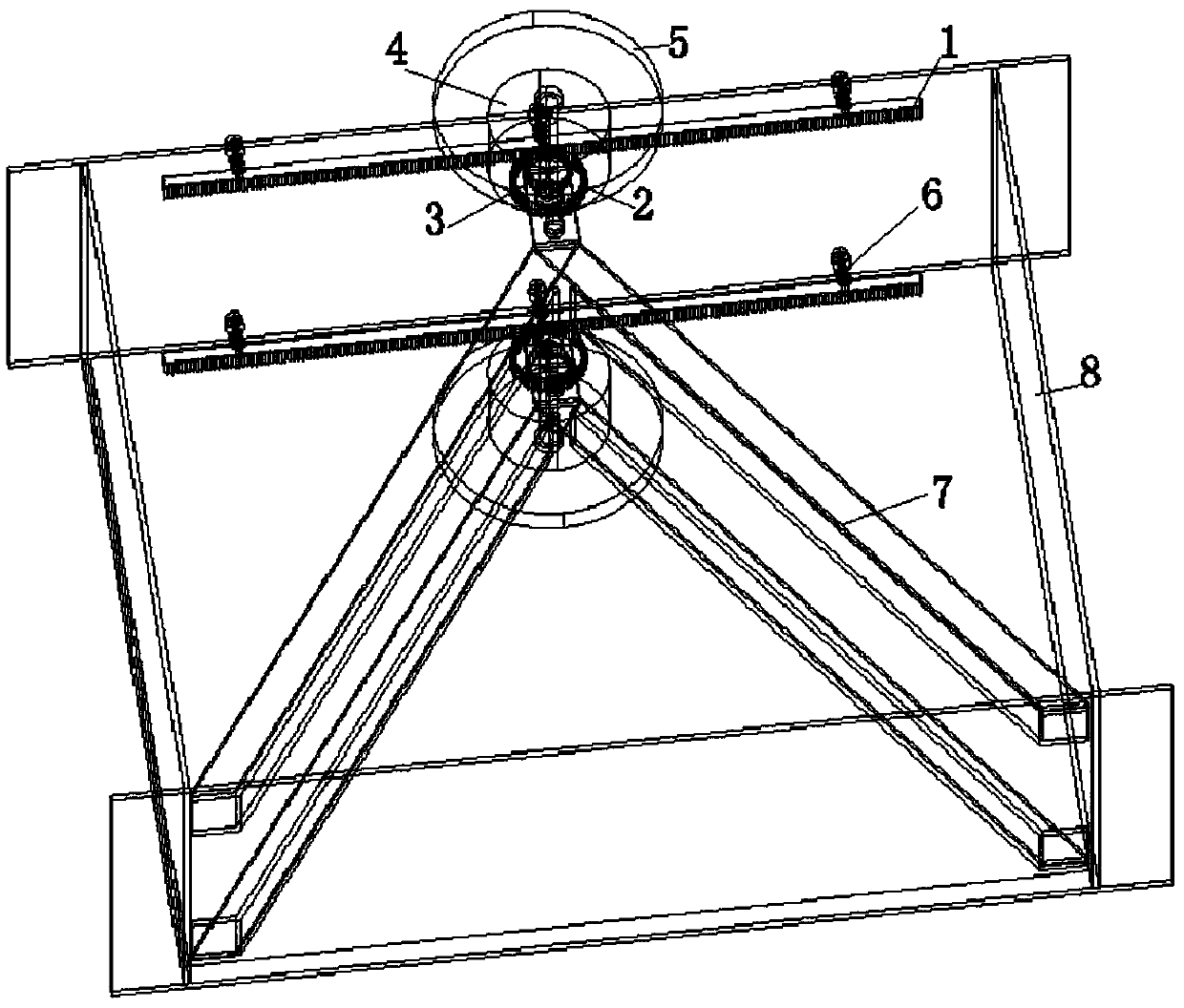

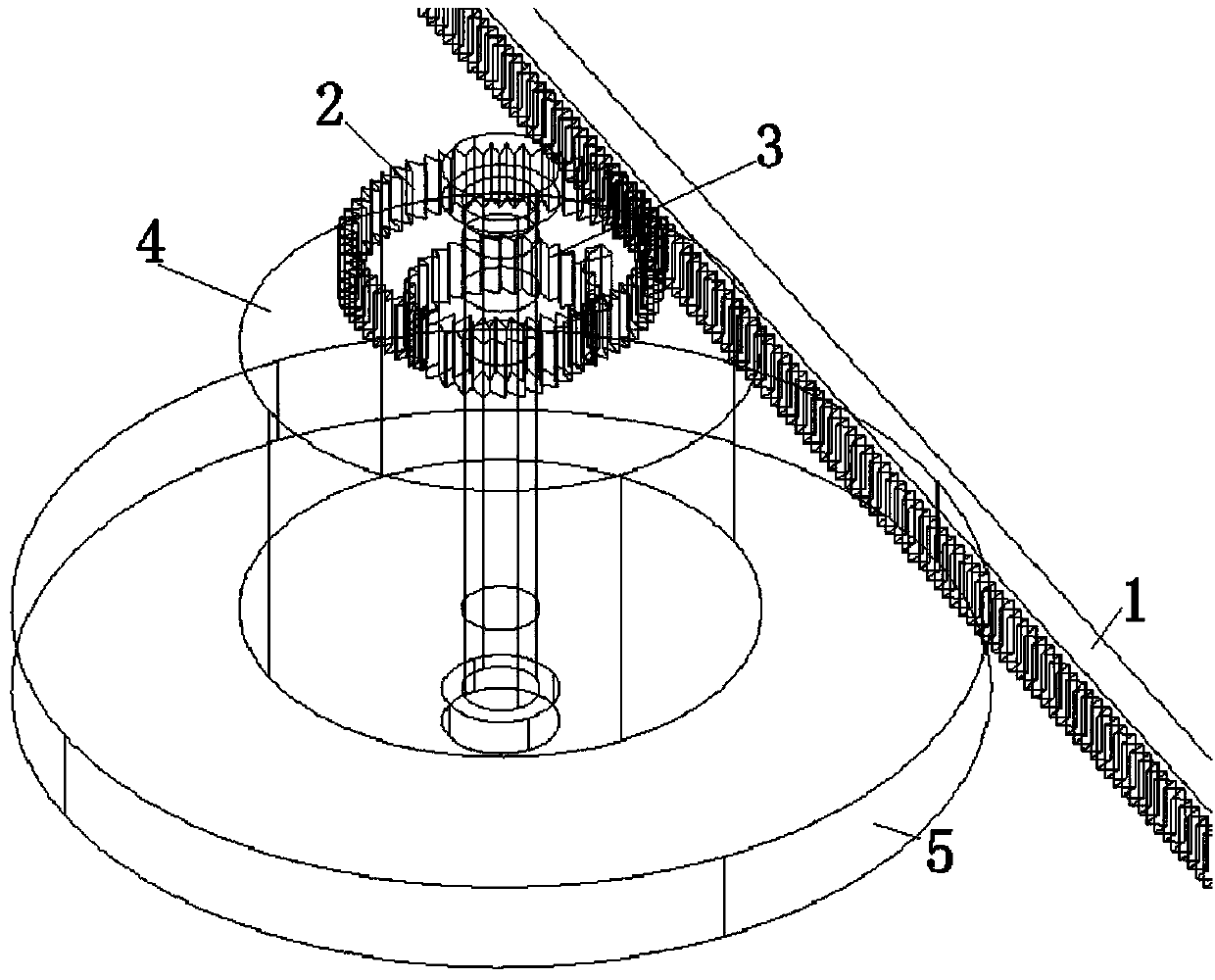

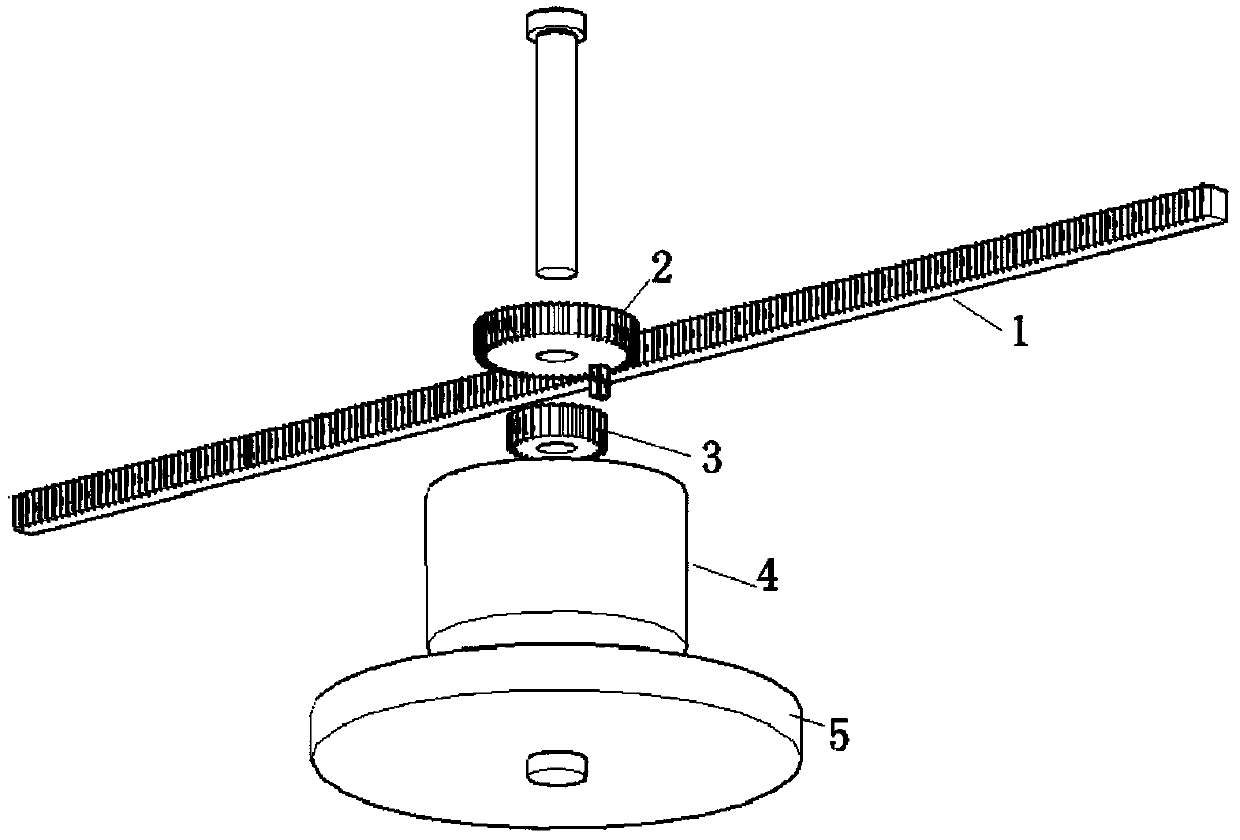

[0039] Such as Figure 1-6 As shown, the present invention provides a ratchet rack container based on a reducer, which has a single-layer frame structure 8, and two racks 1 are respectively arranged on the lower surface of the frame top plate along the length direction of the single-layer frame structure 8 On both sides, and the teeth of the rack 1 face downward, and are riveted to the top plate by bolts at the same time, and a spring is arranged outside the bolt to form a bolt spring 6 to automatically adjust the distance between the rack 1 and the top plate. Fixed on the upper surface of the bottom plate of the frame, the inerter includes: two gears 2, the gears 2 are respectively meshed with two racks 1 for transmission, and are fixedly equipped with one-way toggle claws, and the claws are accompanied by the gears 2 Rotation; two ratchets 3, the ratchets 3 are respectively arranged on the outer side of the single-layer frame structure 8 than the two gears 2, and are engaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com