Adhesive sticker material flatness detector with local detection function

A flatness detector and local detection technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of measurement, measurement accuracy can not be guaranteed, inconvenient operation, etc., to achieve rapid measurement, convenient operation, measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

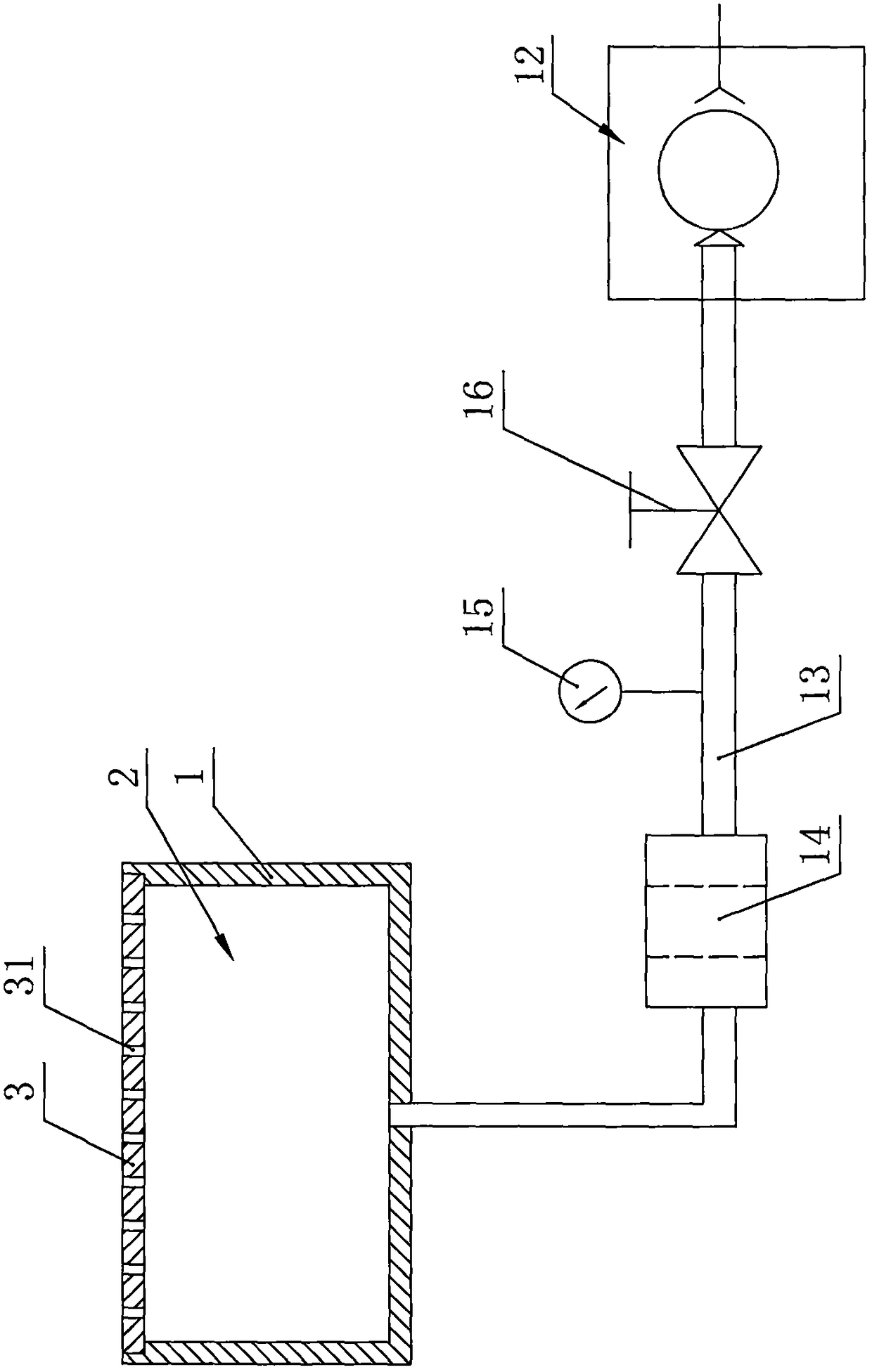

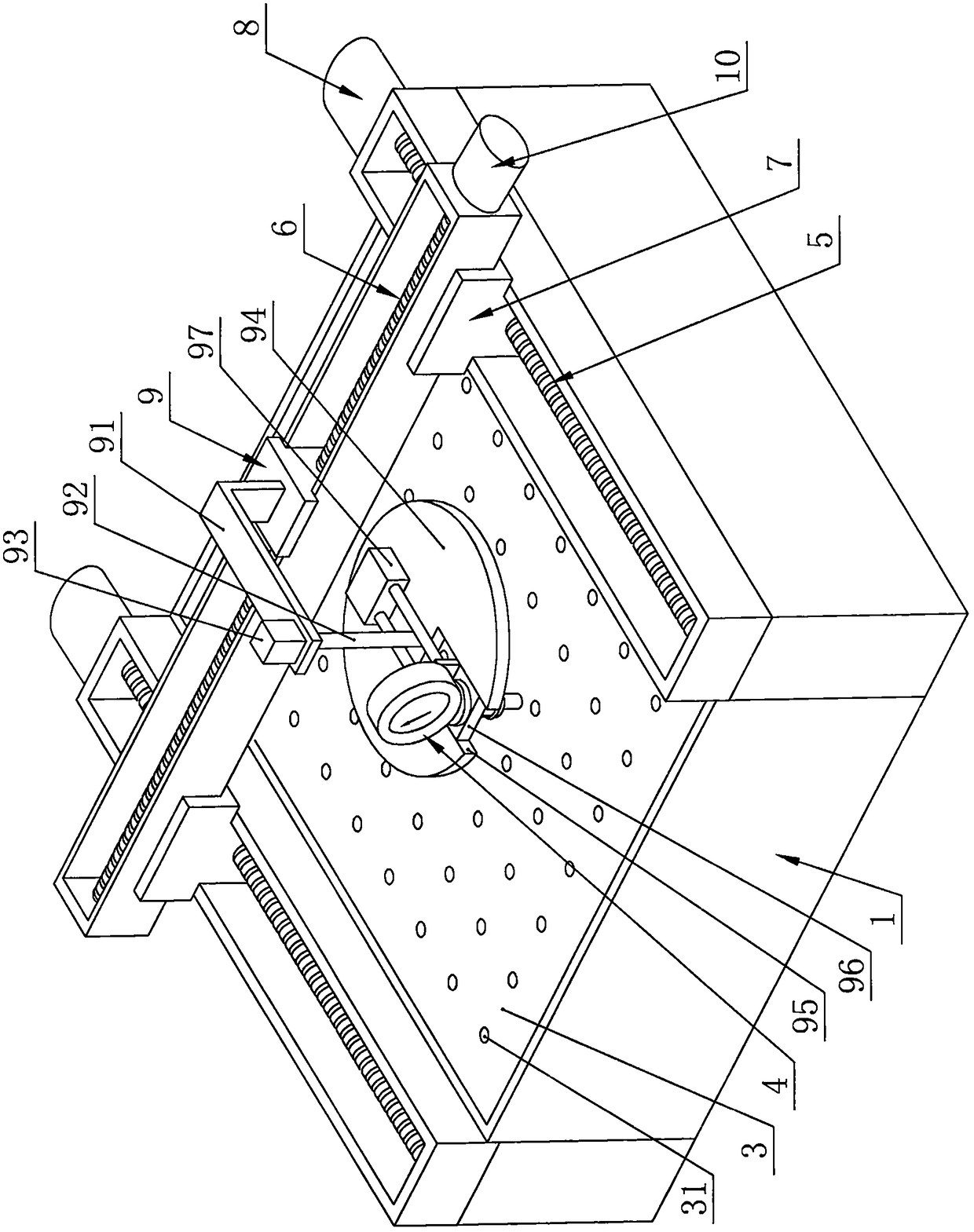

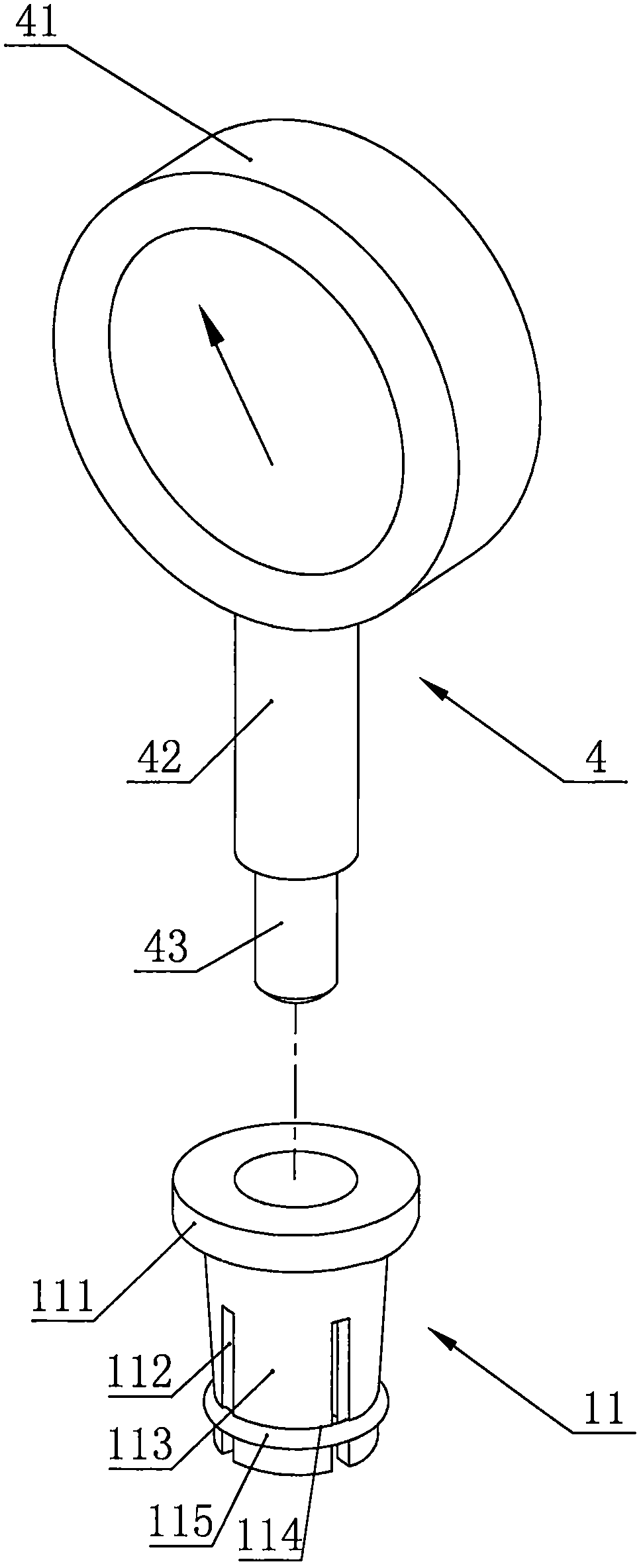

[0014] Such as figure 1 , 2 , 3 shows a self-adhesive material flatness detector with local detection, including a workbench 1, a concave cavity 2 is arranged on the workbench 1, and a pair of concave cavities is fixed on the workbench 1. 2 constitute the detection plate 3 of the cover, the detection plate 3 is evenly distributed with a plurality of through holes 31 that are in communication with the cavity 2, and the cavity 2 of the workbench 1 is also connected with a vacuum device, the The working table 1 is equipped with a measuring device for detecting the flatness of the self-adhesive material laid on the detection plate 3, and the measuring device includes a dial gauge 4 and is used to drive the dial gauge 4 relative to the detection plate The moving mechanism of moving, described moving mechanism comprises longitudinal slide rail 5 and transverse slide rail 6, and longitudinal slide rail 5 is fixed on the workbench 1, and vertical slide rail 5 is slidingly equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com