Over-temperature warning nut

A nut, over-temperature technology, applied in the field of temperature monitoring, can solve the problems of being easily affected by the environment, low measurement accuracy of connecting fittings, etc., and achieve the effect of eliminating potential safety hazards, simple structure and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

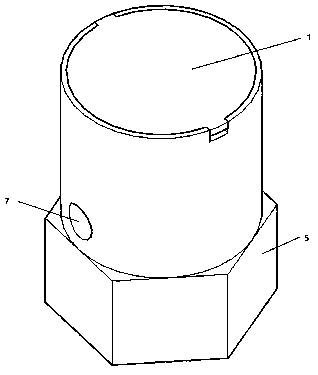

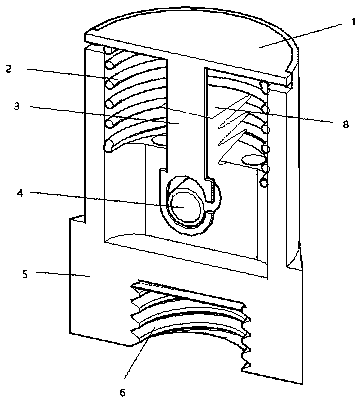

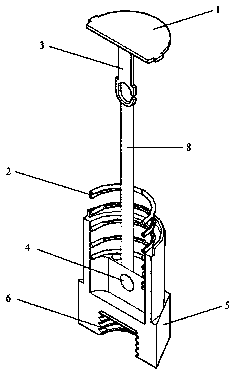

[0030] An over-temperature warning nut, such as figure 1 and figure 2 As shown, it includes a nut 5, a temperature-sensitive glass bulb 4 fixed on the top of the nut 5, a terminal fixedly connected to the top of the temperature-sensitive glass bulb 4 at the bottom, a spring cover 1, a pull rod 3, a pressure spring 2 and a warning tape 8; The terminal is in the shape of a cylinder with an open top and a closed bottom, and a through hole is opened at the bottom; the spring cover 1 covers the opening at the top of the terminal, and is fixed with the temperature-sensitive glass ball 4 through the through hole through the pull rod 3 Connection; the pressure spring 2 is arranged in the terminal, and its two ends are respectively connected / contacted with the spring cover 1 and the bottom end of the terminal; the two ends of the warning tape 8 are respectively connected with the spring cover 1 and the inner wall of the terminal.

[0031] Nuts are widely used in connection fittings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com