A push-and-shake combined wave generator

A wave-making machine and combined technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of reducing experiment efficiency and increasing experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

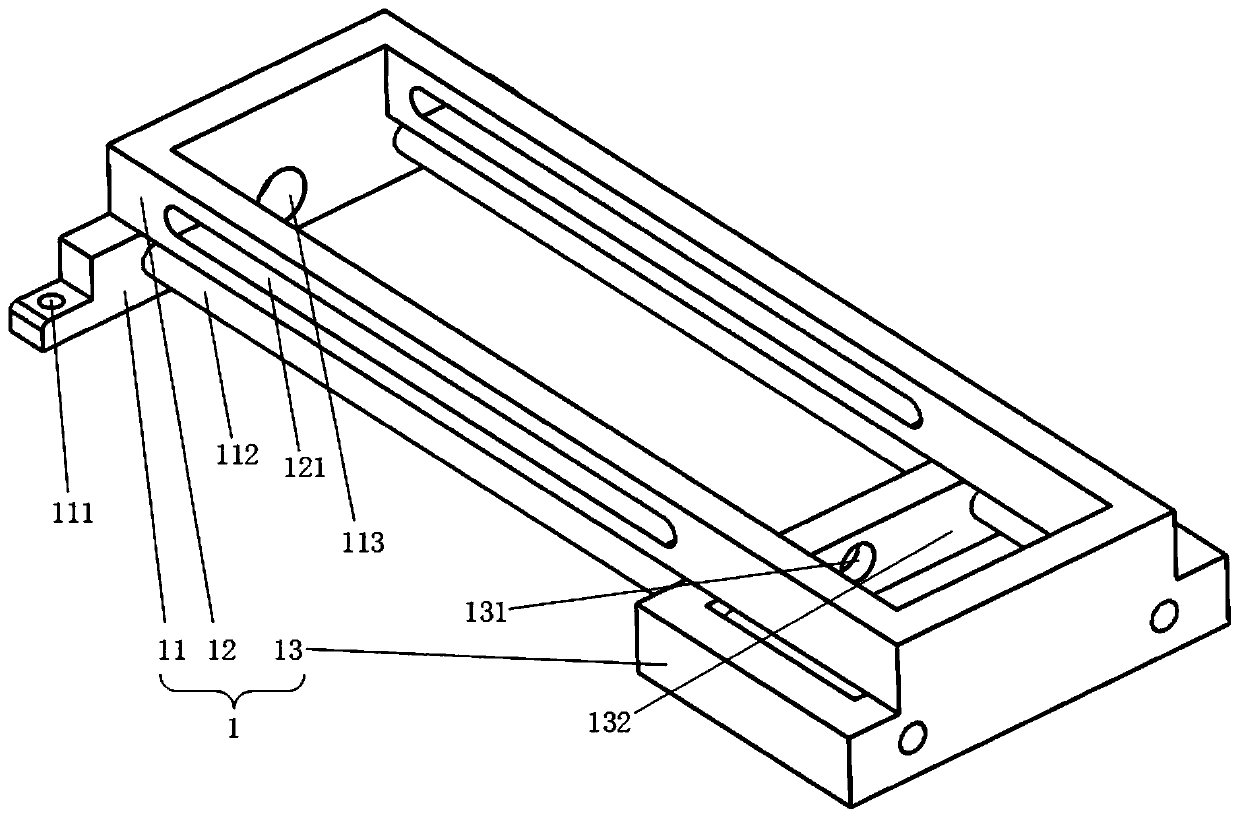

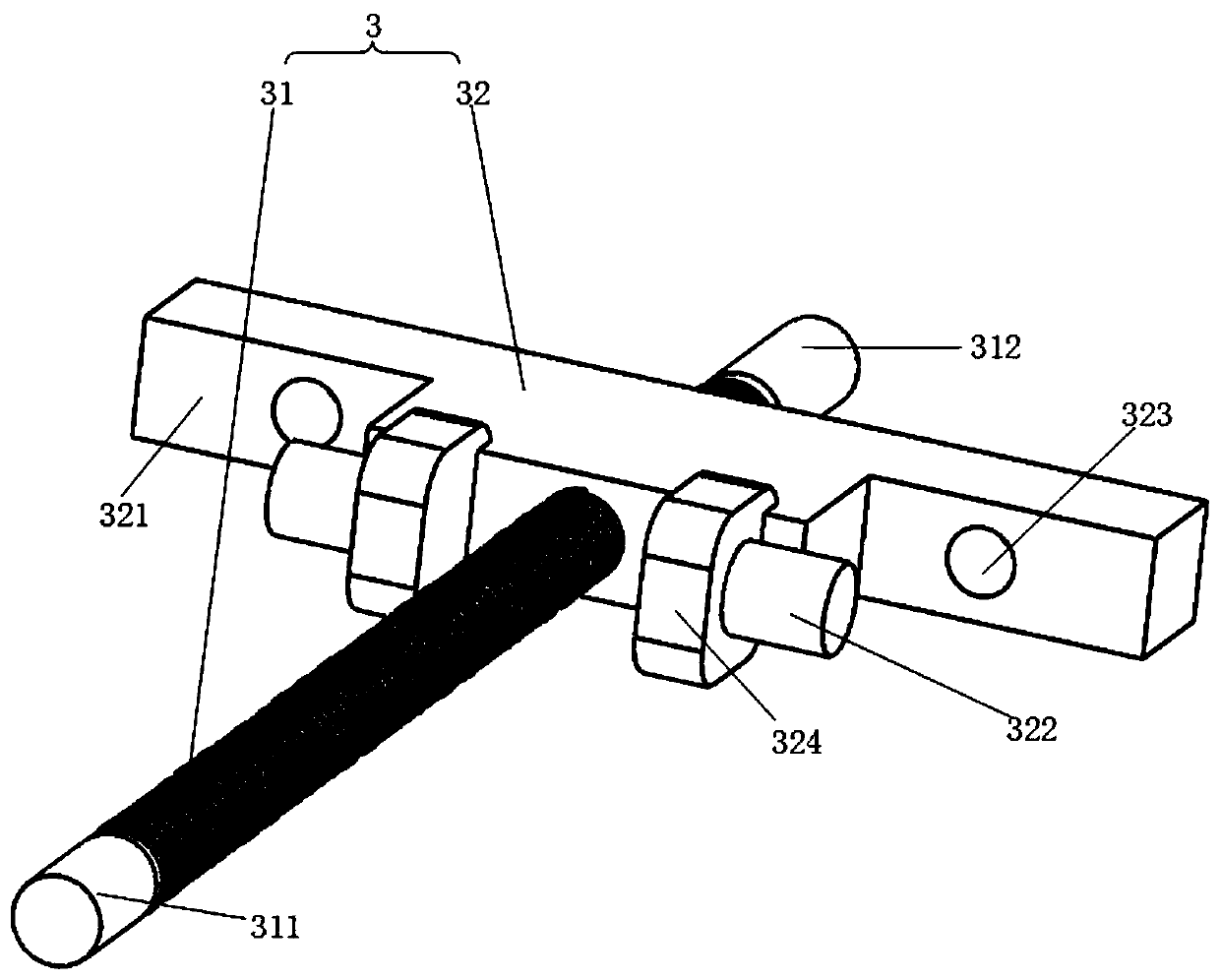

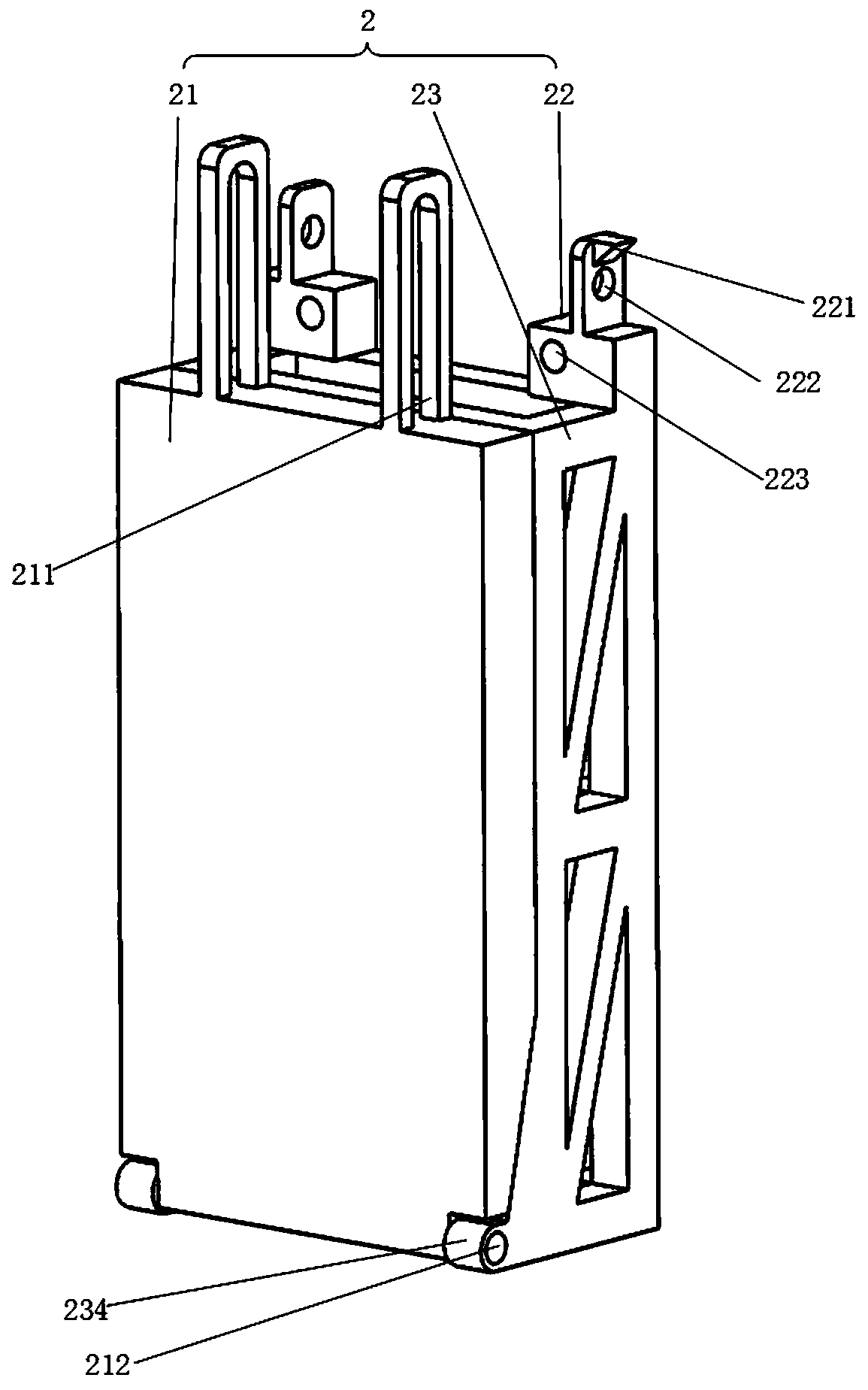

[0026] exist Figure 1 to Figure 10 In the schematic diagram of the present invention, the back seat is a square frame, the back seat is provided with a front end face 52 of the back seat, and a crossbeam 51 is provided in the middle of the top of the back seat. One end of the guide rail support frame of the guide rail support is fixed on the top of the rear seat 5. A second lead screw hole 131 and two groups of guide rail holes are opened on the guide rail support frame, and the positions of the second lead screw holes correspond to the positions of the first lead screw holes. A first lead screw hole 113 and two guide rail holes are opened on the guide rail support boss 11 . The first servo motor 9 is fixed on the rear seat beam, the output end of the first servo motor is connected to the rear end 312 of the lead screw through a coupling, and the lead screw extends to the guide rail support frame through the corresponding second lead screw hole of the guide rail support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com