Device and method for length fixing and notch positioning of welded joint impact specimens

A technology of impact specimens and welded joints, which is applied in the field of material testing specimen processing, can solve problems such as low efficiency, difficulty in checking the correctness of the notch position, cumbersome processing of impact specimens, etc., and achieve the effect of fast batch length fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

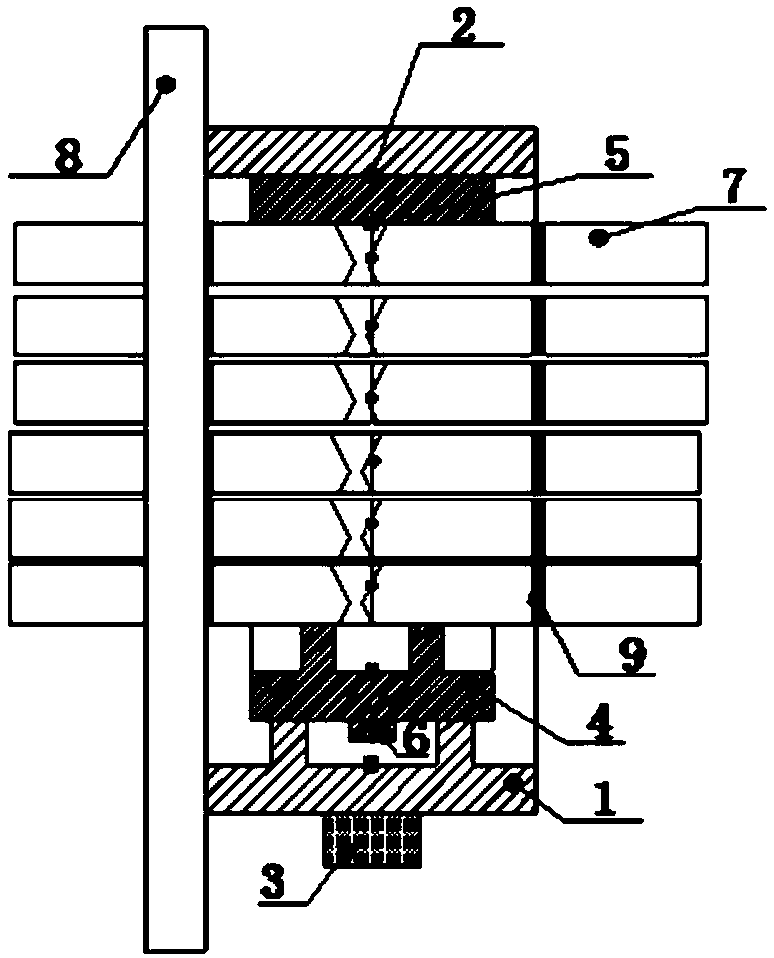

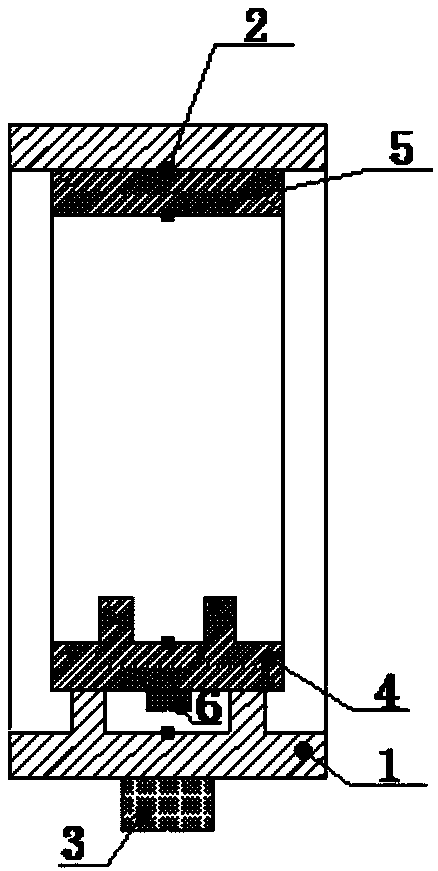

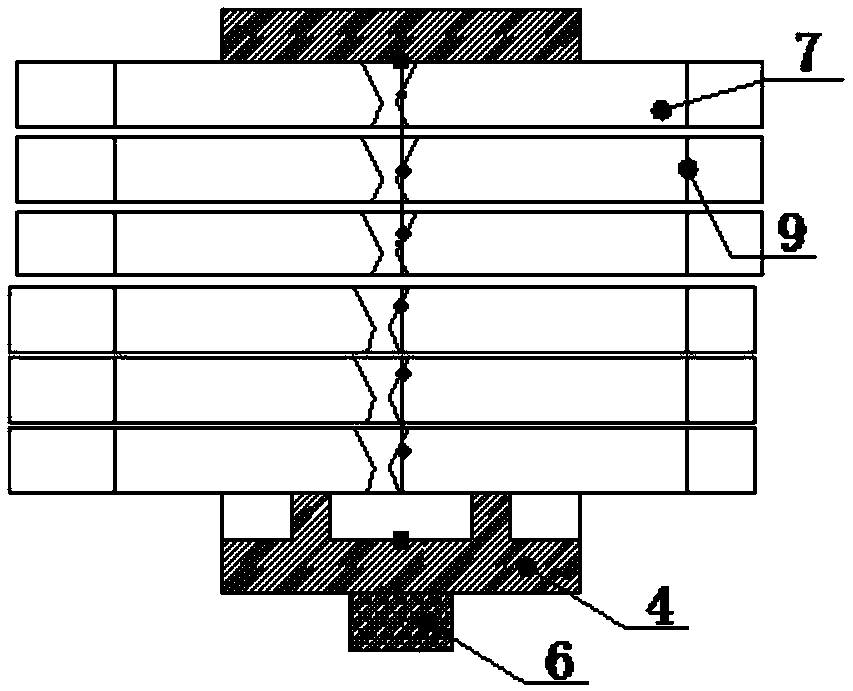

[0029] The implementation method of using the above-mentioned device to determine the length of the sample and locate the gap comprises the following steps:

[0030] Step 1: After corroding the two opposite surfaces of each sample to show the outline of the weld, mark the notch position points respectively;

[0031] Step 2: Arrange several sample blanks with marked position points into the cutting fixture 4, then put the cutting fixture 4 into the fixed-length fixture 1, and then use the ruler 8 to assist along the fixed length. The long center point 2 and the cutting center point 5 are arranged so that the position points marked on each sample blank, the fixed-length center point 2 and the cutting center point 5 are on the same straight line, and then respectively The cutting clamping knob 6 and the fixed-length clamping knob 3 are tightened, and then the straight line is drawn on each sample blank, and a straight line mark 11 is formed on the sample blank, and the operation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com