Motor installing structure and compressor

A technology for installation structure and compressor, which is applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., which can solve the problem of difficulty in cost reduction, large amount of material used for the stator core of the motor stator compressor base, and reliable motor stator low stability and other issues, to achieve the effect of reducing offline rate, enhancing market competitiveness, and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

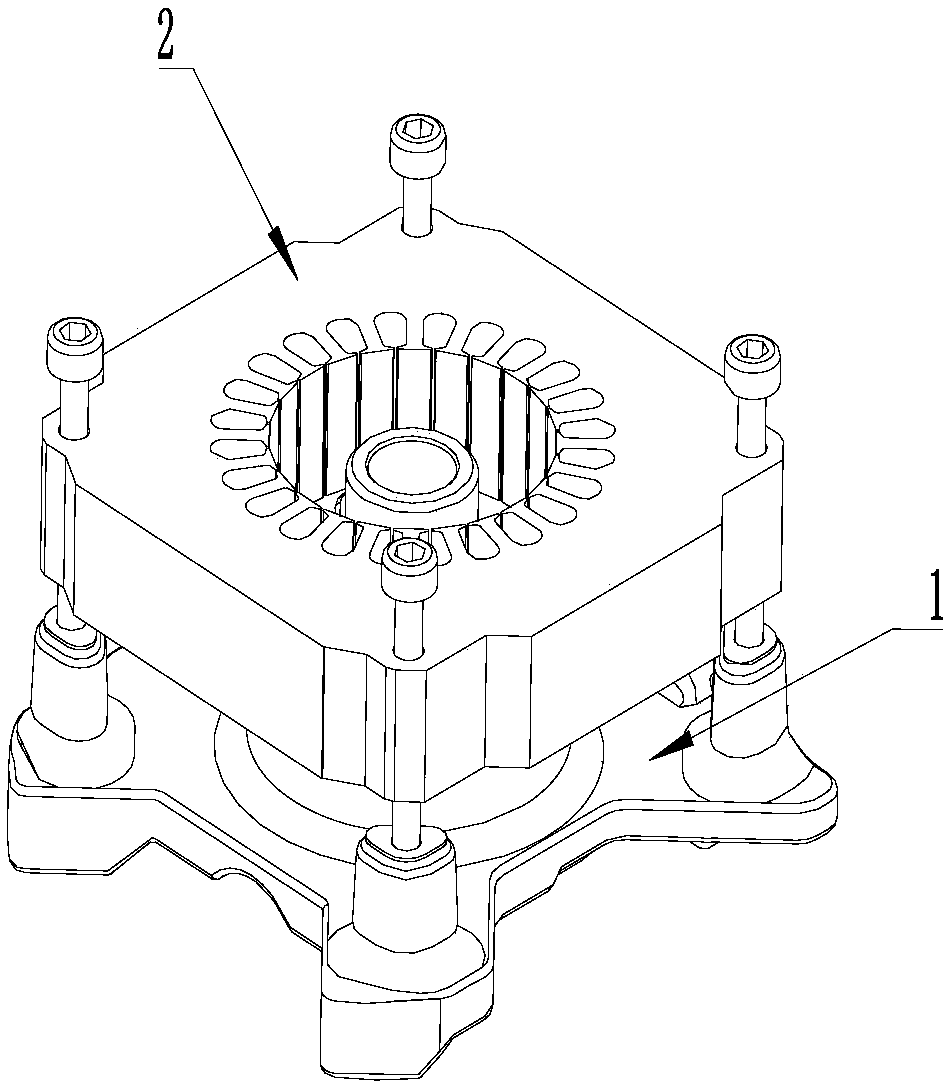

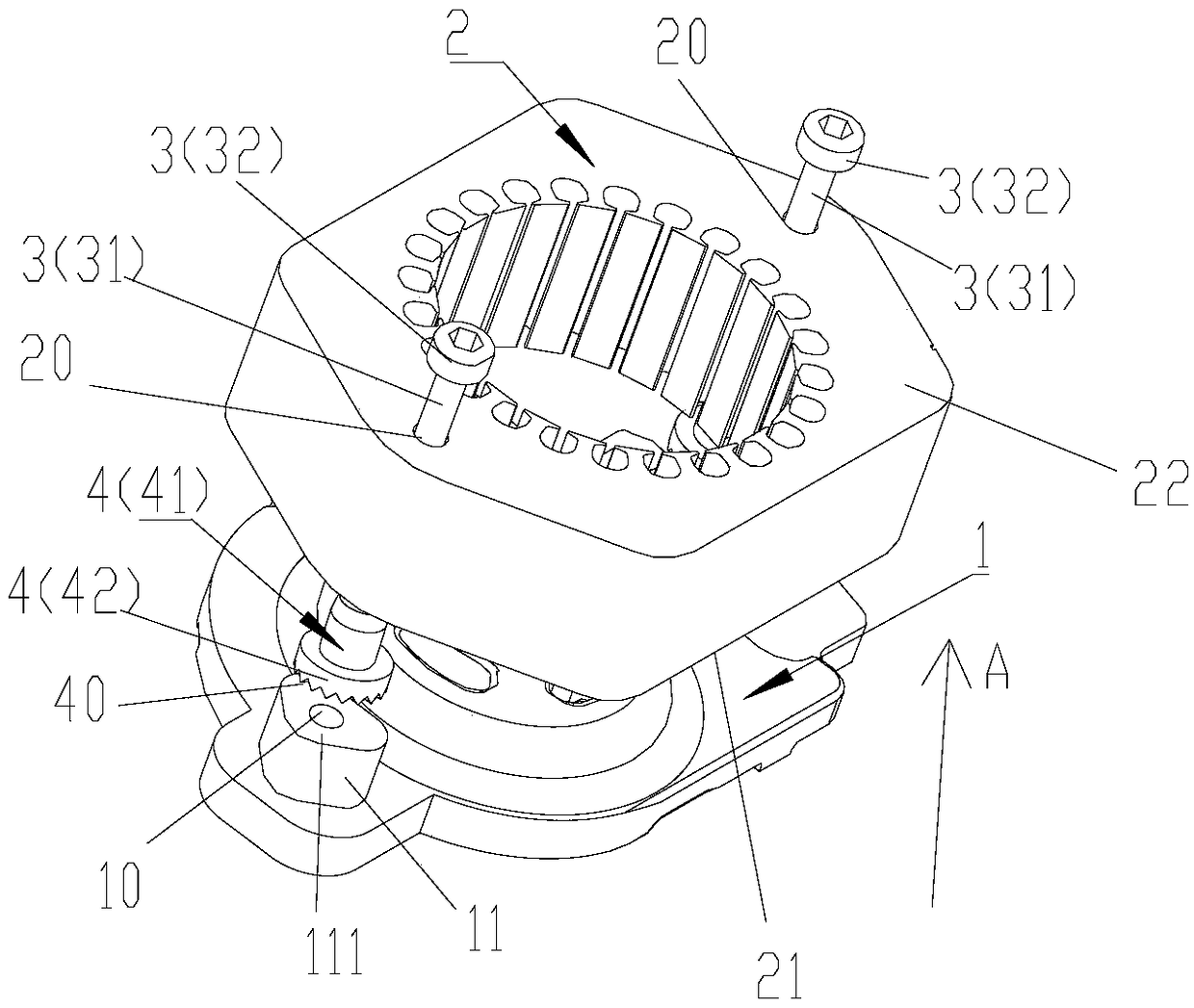

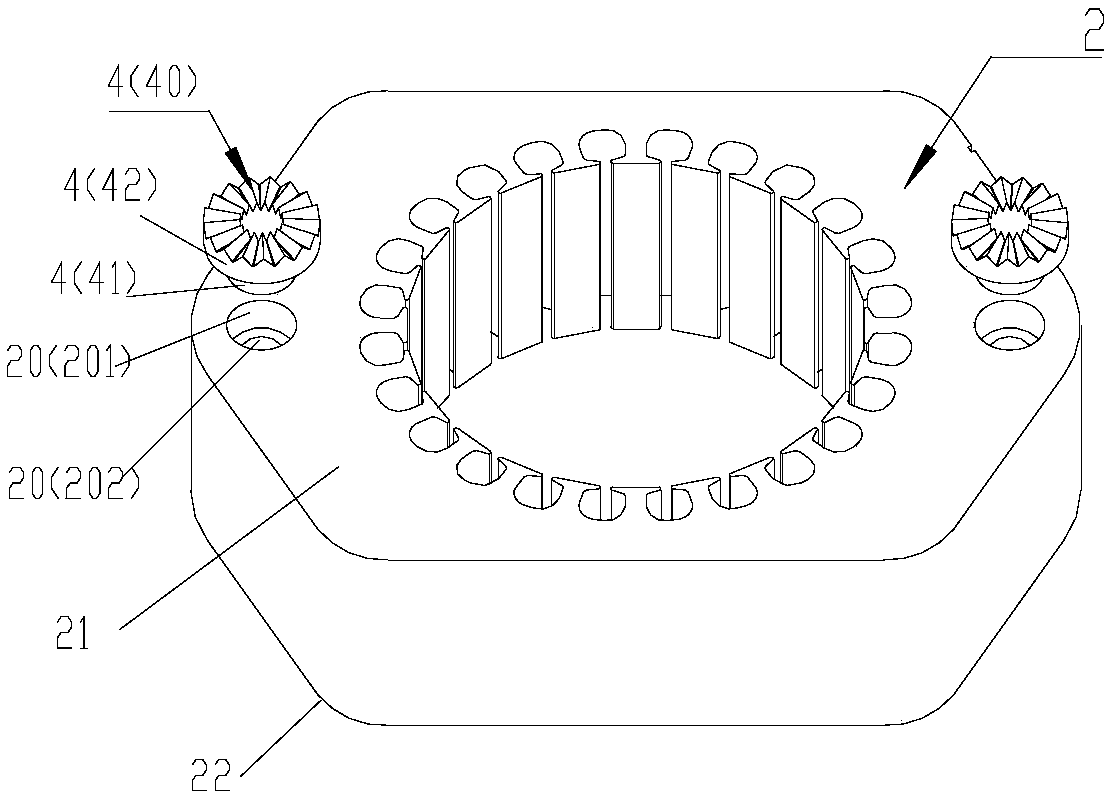

[0041] like Figure 2-4b As shown, the present invention provides a motor mounting structure, which includes:

[0042]A bracket base 1, the bracket base 1 is provided with a mounting platform 11, and the mounting platform 11 is provided with a first mounting hole 10;

[0043] The motor stator 2 is provided with a second mounting hole 20 corresponding to the first mounting hole 10;

[0044] The threaded connector 3 includes a screw 31, and the screw 31 can pass through the first installation hole 10 and the second installation hole 20 at the same time;

[0045] The positioning pin 4 can be inserted into the second mounting hole 20, and the positioning pin 4 has an inner middle hole 44 passing through the interior of the positioning pin along its length direction, and the inner middle hole 44 can allow the screw rod 31 pass through (the diameter of the inner middle hole is not less than the diameter of the screw rod), and the mounting surface of the positioning pin 4 opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com