Tubular lead-acid storage battery and manufacturing method thereof

A technology for lead-acid batteries and manufacturing methods, applied in the direction of lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve the problem of increasing the contact area between the surface of the tubular electrode and the surface of the separator, and the volume of the tubular lead-acid battery Large, small volume specific energy, etc., to improve softening or/and shedding, improve life, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

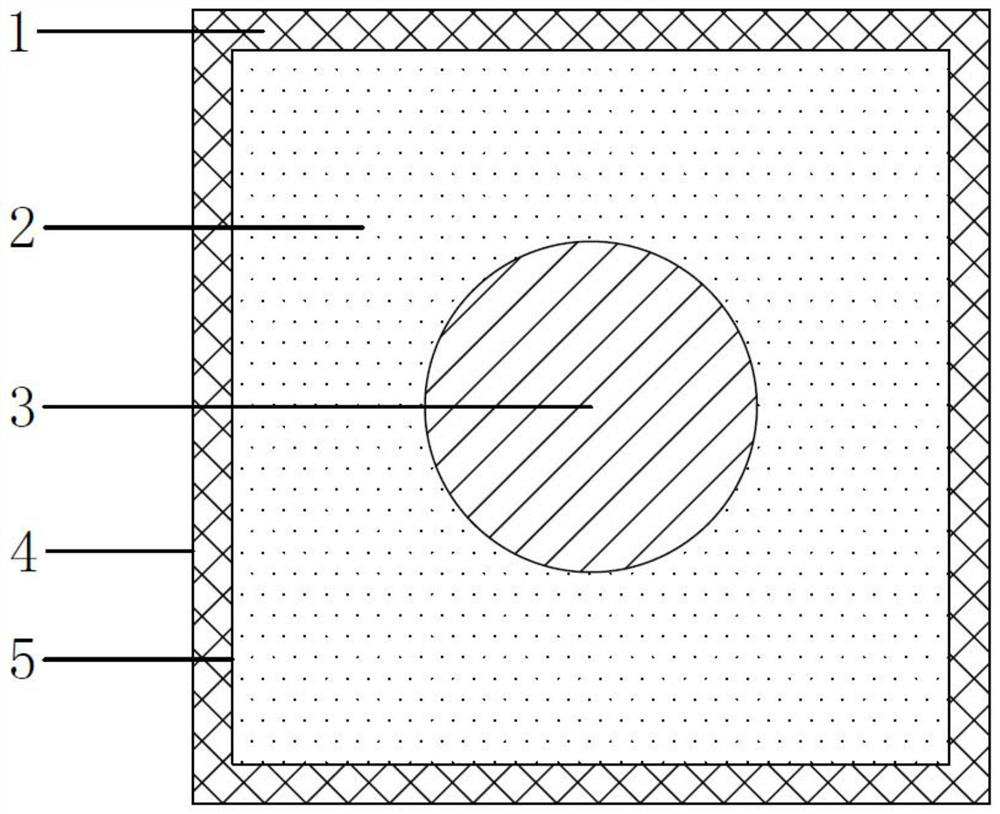

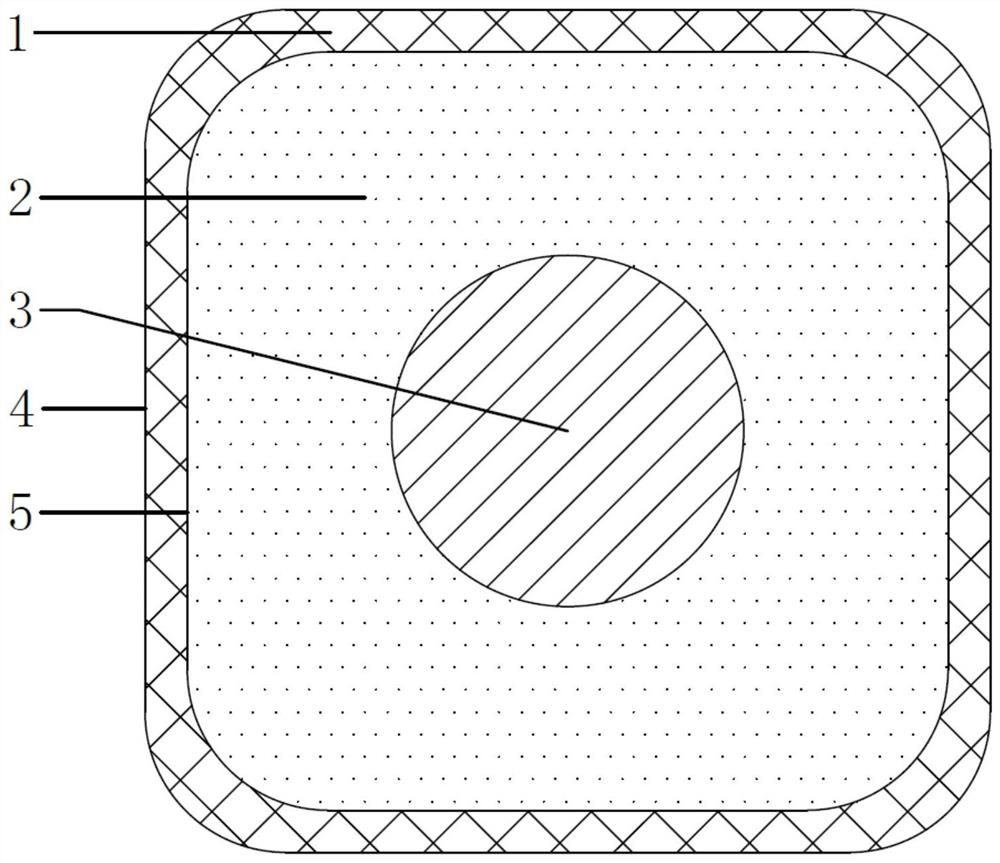

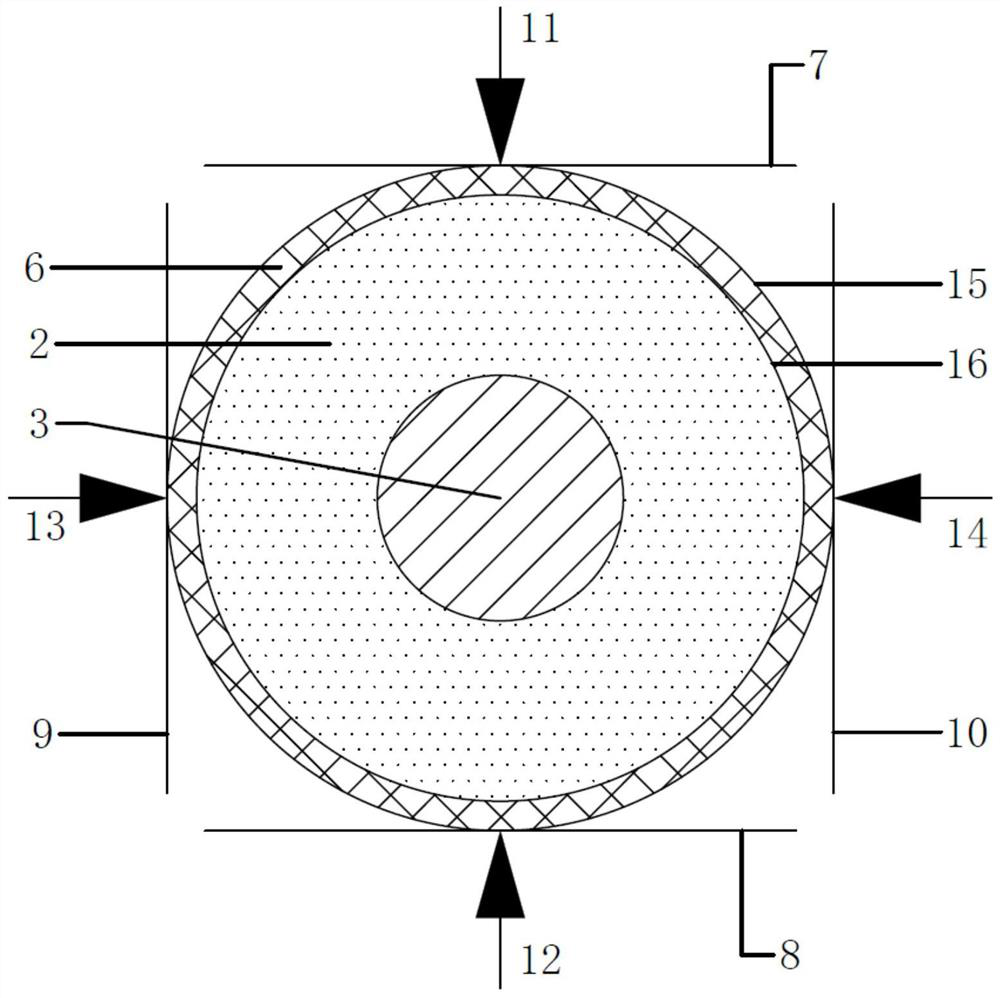

[0105] The tubular lead-acid storage battery of this embodiment comprises a square tubular electrode, such as figure 1 As shown in -2, the square tubular electrode in this embodiment includes: a porous square tube 1, an active material 2, and a cylindrical conductive bone core 3, wherein the active material 2 is in contact with the cylindrical conductive bone core 3, and both are contained in In the porous square tube 1, the porous square tube 1 or the active material 2 of the square tube electrode in this embodiment has more than one surface plane 4 or 5, and the diameter of the square tube electrode or its porous square tube 1 or its active material 2 The cross-sectional shape is square ( figure 1 ), rounded squares ( figure 2 ).

[0106] The aforementioned square tubular electrode in this embodiment is obtained through a certain manufacturing method. The manufacturing method includes: selecting a round tubular electrode, and the round tubular electrode is, for example, ...

Embodiment 2

[0112] The tubular lead-acid storage battery of this embodiment comprises rectangular tubular electrodes, such as Figure 4 , 5 As shown, the rectangular tubular electrode in this embodiment includes: a porous rectangular tube 17, an active material 2, and a rectangular columnar conductive bone core 18, wherein the active material 2 is in contact with the rectangular columnar conductive bone core 18, and both Contained in the porous rectangular tube 17, the porous rectangular tube 17 or the active material 2 of the rectangular tubular electrode in this embodiment has more than one surface plane 4, 5, the tubular electrode or its porous rectangular tube 17 or its The radial cross-sectional shape of the active material 2 is a rectangle ( Figure 4 ), rounded rectangle ( Figure 5 ).

[0113] In this embodiment, the above-mentioned rectangular tubular electrode is manufactured through a certain manufacturing method, and the manufacturing method includes: selecting a circular t...

Embodiment 3

[0118] The tubular lead-acid battery of this embodiment includes elliptical tubular electrodes with 2 curved surfaces deformed into 2 planes, such as Figure 7 As shown, the elliptical tubular electrode with two arc surfaces deformed into two planes in this embodiment includes: an oval tube 19 with two arc surfaces deformed into two planes, an active material 2, and a rectangular columnar conductive bone core 18, wherein the active material 2 and Rectangular columnar conductive bone core 18 is in contact, and both of them are contained in an oval tube 19 whose two arc surfaces are deformed into two planes. In this embodiment, the oval tube 19 with two arc surfaces deformed into two planes or the active material 2 has a Above the surface planes 4 and 5, the tubular electrode or its 2 arcs are deformed into 2 planar elliptical tubes 19 or the radial cross-sectional shape of its active material 2 is an ellipse with 2 arcs deformed into 2 straight sides ( Figure 7 ).

[0119] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com