Improved capacitor base

A capacitor and seat technology, applied in capacitor parts and other directions, can solve the problems of melting solder, capacitor short circuit, lead breakage, etc., to ensure normal use, reduce shaking, and strengthen the effect of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

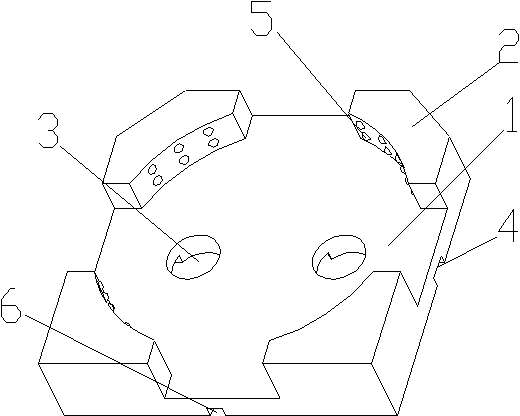

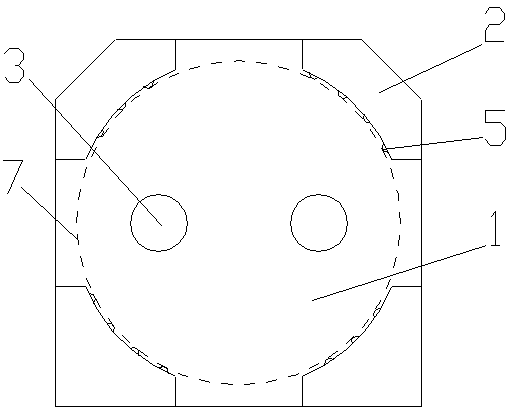

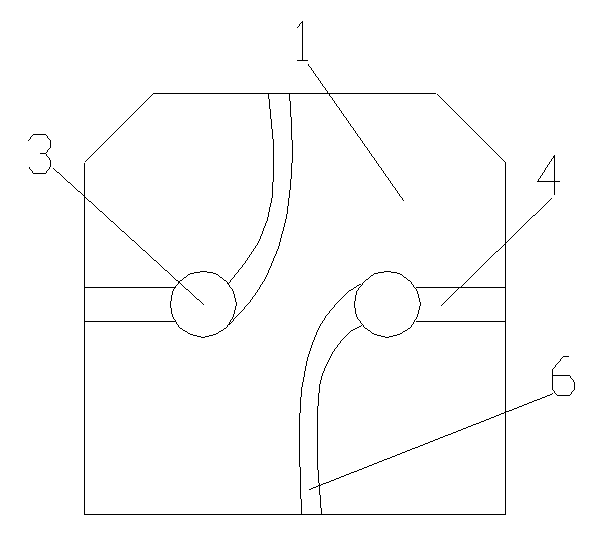

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 , 2 An improved capacitor base shown includes a seat body 1, several arc-shaped bosses 2 are provided on the top of the seat body 1, and two symmetrical electrode lead-out holes 3 are provided in the middle of the seat body 1. The bottom of the body 1 is provided with an electrode lead groove 4, one end of the electrode lead groove 4 communicates with the electrode lead-out hole 3, and the other end communicates with the outer edge of the base body 1, and it is characterized in that each arc-shaped convex A number of hemispherical projections 5 that are evenly arranged and of equal size are arranged on the inner arc surface of the table 2, and the plurality of hemispherical projections 5 form an inner circular cavity 7 that coincides with the outer circle of the patch capacitor; the hemispherical The distance between the highest point of the shaped protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com