Mounting method for energy-saving conduit of ultra large crude carrier in block stage

An installation method and super-large technology, applied in transportation and packaging, ship parts, ships, etc., can solve problems such as crane coordination and installation difficulty, and achieve the effects of saving construction costs, improving construction efficiency, and shortening construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

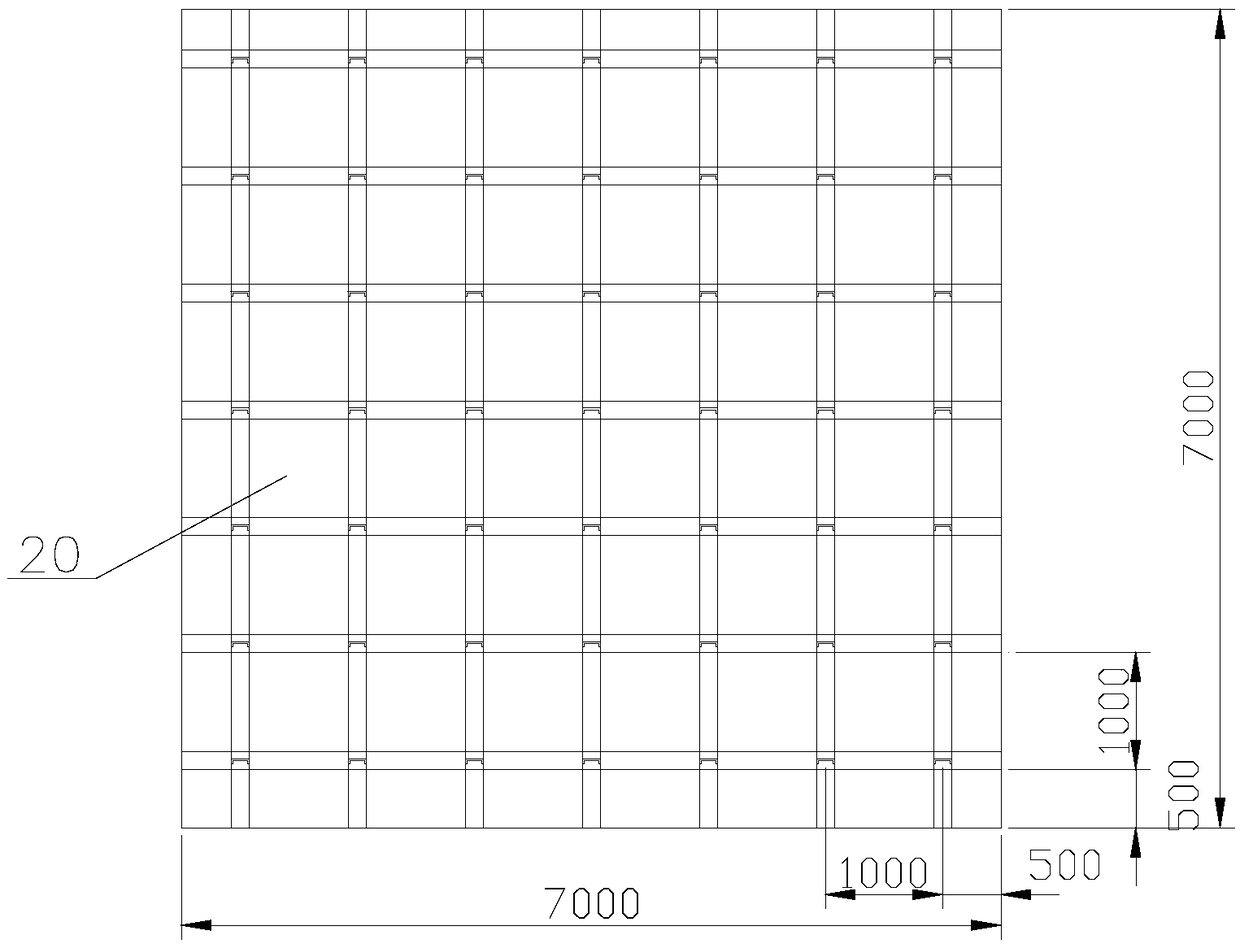

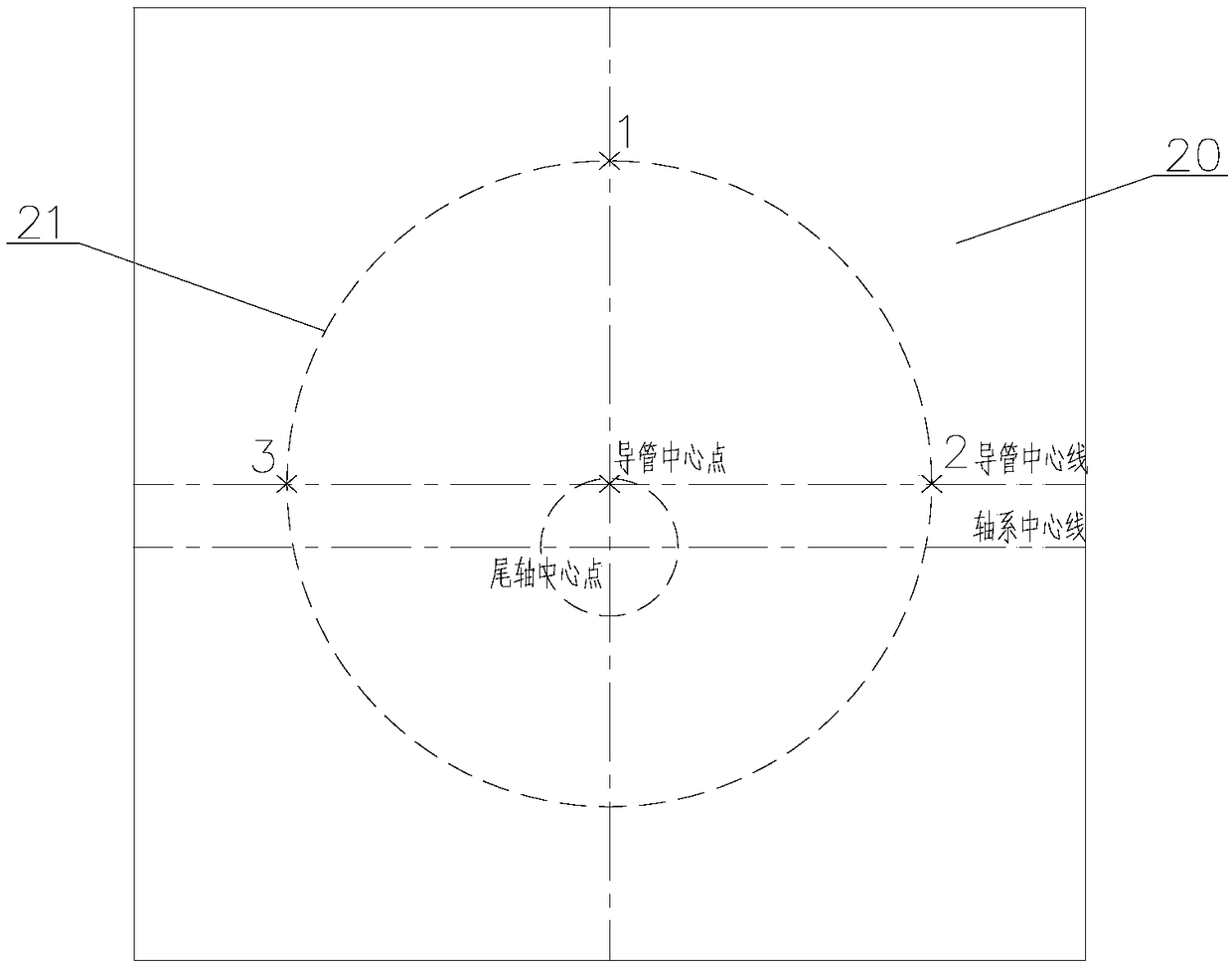

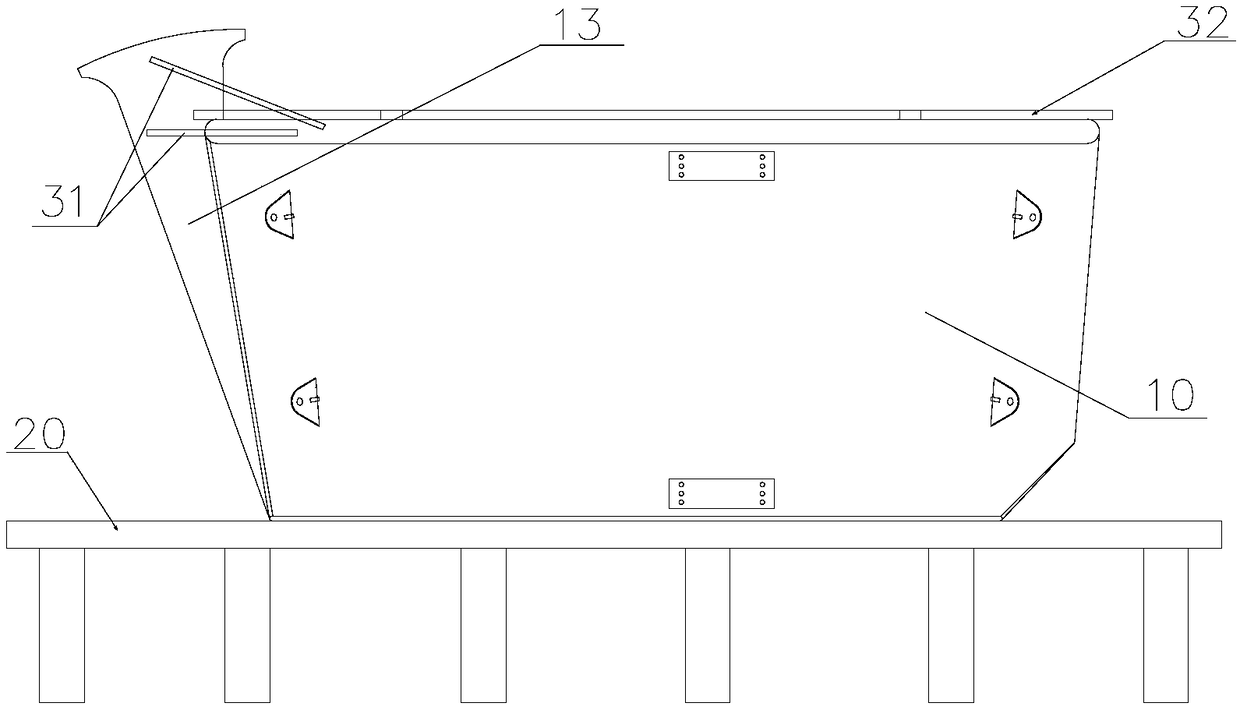

[0040] The energy-saving conduit involved in the installation method of the ultra-large tanker energy-saving conduit of the present invention is an unclosed conical cylindrical structure. The outer diameter of the front end of the energy-saving conduit is 7176mm, the inner diameter of the rear end is 6100mm, and the length is 2968mm; In the subsection stage, the energy-saving duct consists of a semicircular port duct and a starboard duct, a central longitudinal bracket that splices the port duct and the starboard duct into one, and four pairs that cover the port duct and the starboard duct and are located on the mid-longitudinal bracket. The cover plates on both sides; the outer surfaces of the port duct and the starboard duct are respectively marked with the duct centerline and the shafting centerline and each has two pairs of lifting rings; the inner surface of the port du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com