Injection mould lifting device

A technology for lifting equipment and injection molds, which is applied in the directions of cranes, load hanging components, transportation and packaging, etc. It can solve the problems that the mold needs to be moved, the mold is heavy, and it is difficult to move manually, so as to reduce the pulling force and facilitate the movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

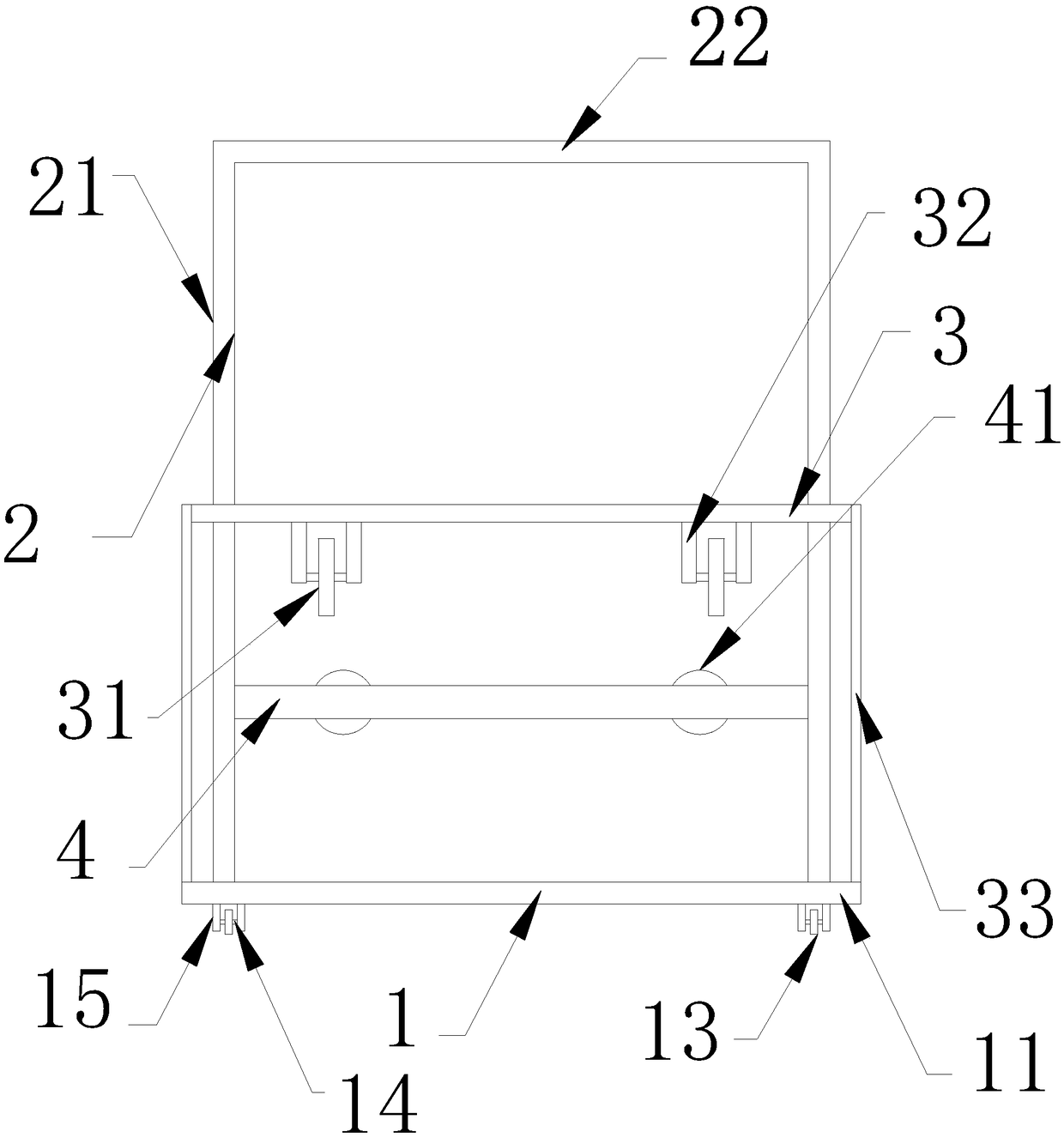

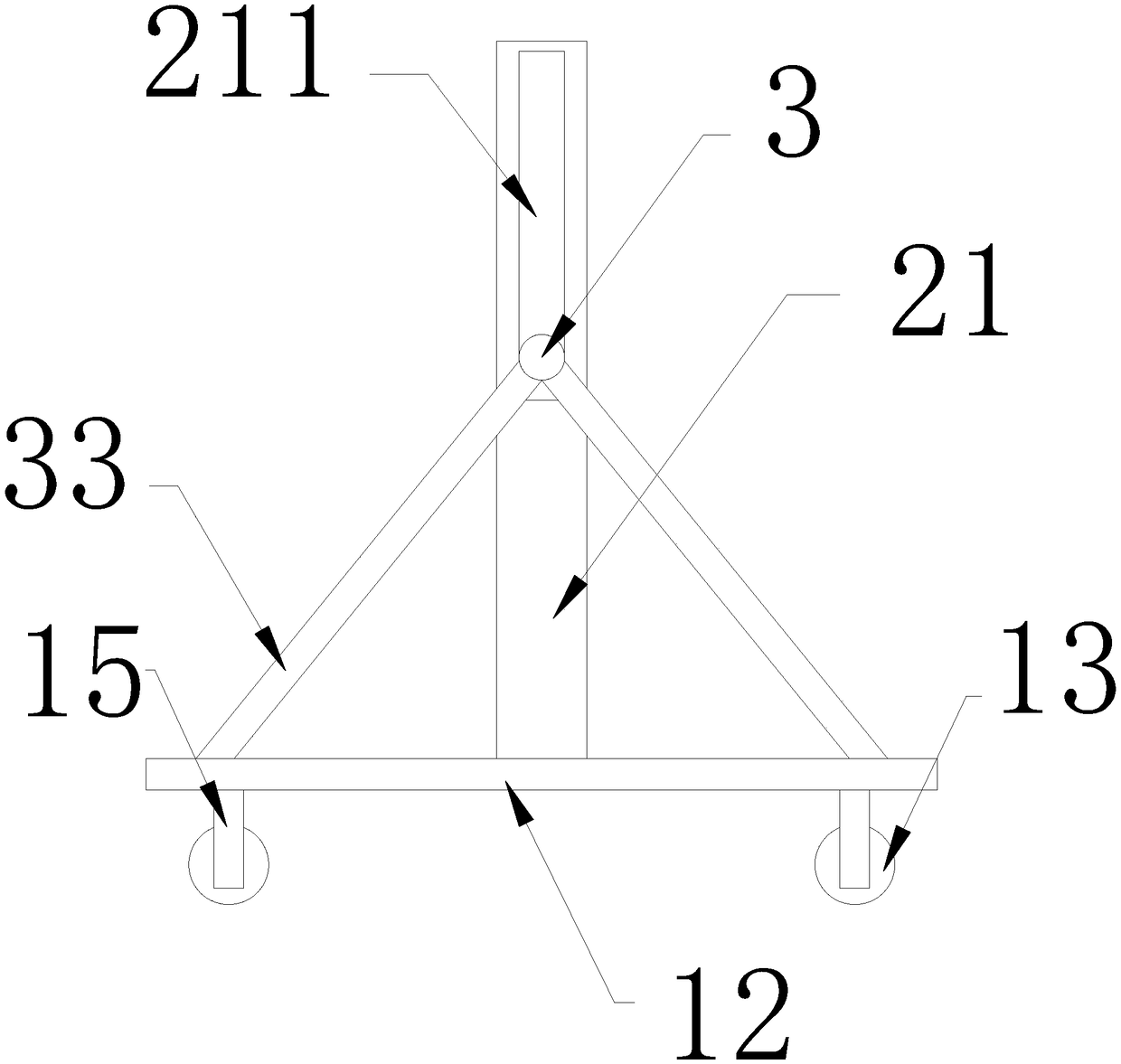

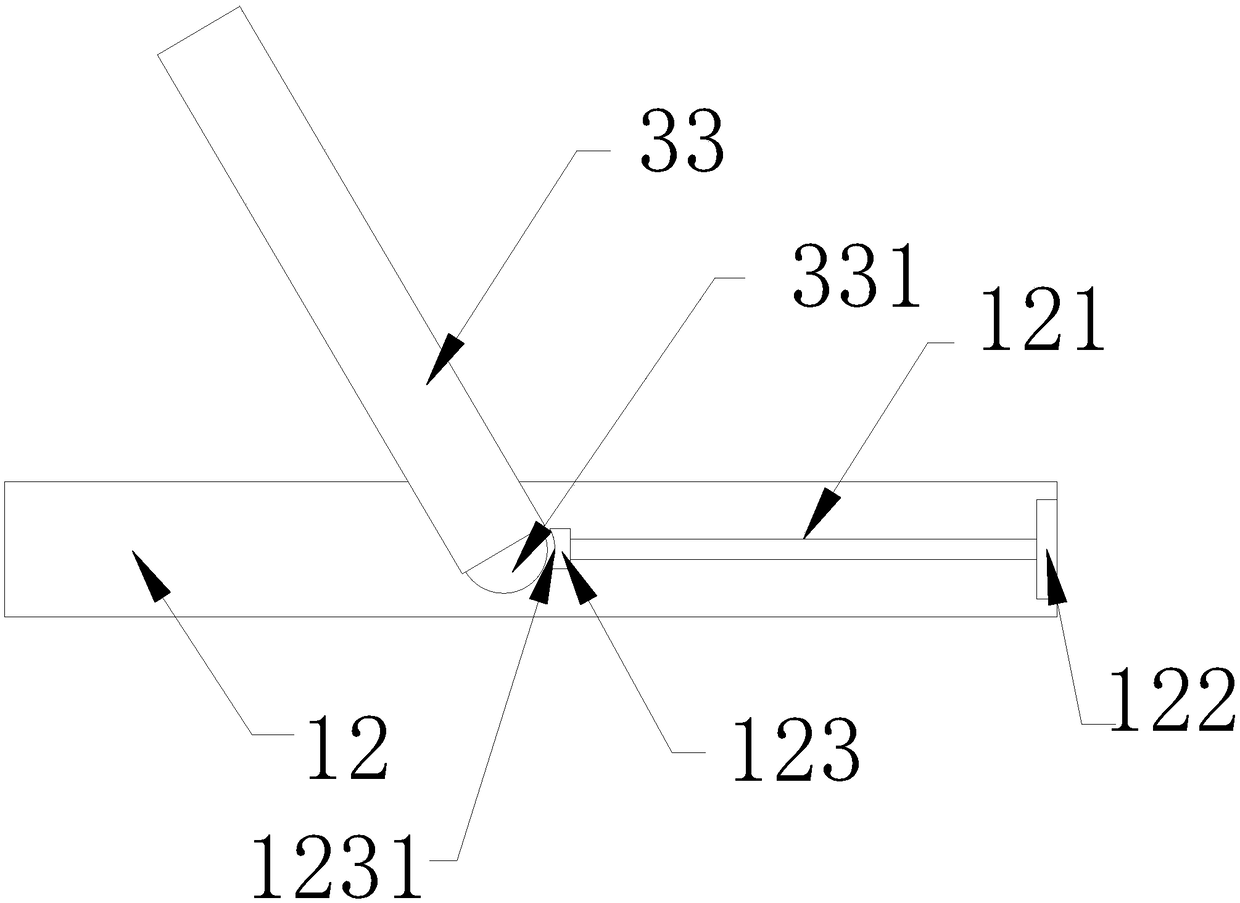

[0022] Example: such as Figure 1-5 As shown, the present invention provides a lifting device for an injection mold, comprising a horizontal frame 1, a vertical frame 2, a lifting rod 3, a steering rod 4 and a controller, and the horizontal frame 1 includes a first frame rod 11, a second Two frame bars 12, the first frame bar 11, the second frame bar 12 are all provided with two, the first frame bar 11, the second frame bar 12 are mutually connected into a rectangular frame; the vertical frame 2 includes a third There are two frame rods 21, a fourth frame rod 22, and two third frame rods 21. One end of the third frame rod 21 is fixedly arranged in the middle of the second frame rod 12, and the other end is connected to the fourth frame rod 22; Said lifting rod 3 passes through the third frame rod 21, and two ends are provided with movable struts 33; said movable struts 33 are provided with four, and one end of the movable struts 33 is fixed with the third frame rod 21 by a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com