Floating butt joint

A butt joint and floating technology, applied in the direction of electrical components, etc., can solve the problems of increasing manufacturing cost, reducing production efficiency, hard steel pipe material, etc., and achieve the effect of reducing manufacturing cost, improving production efficiency, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

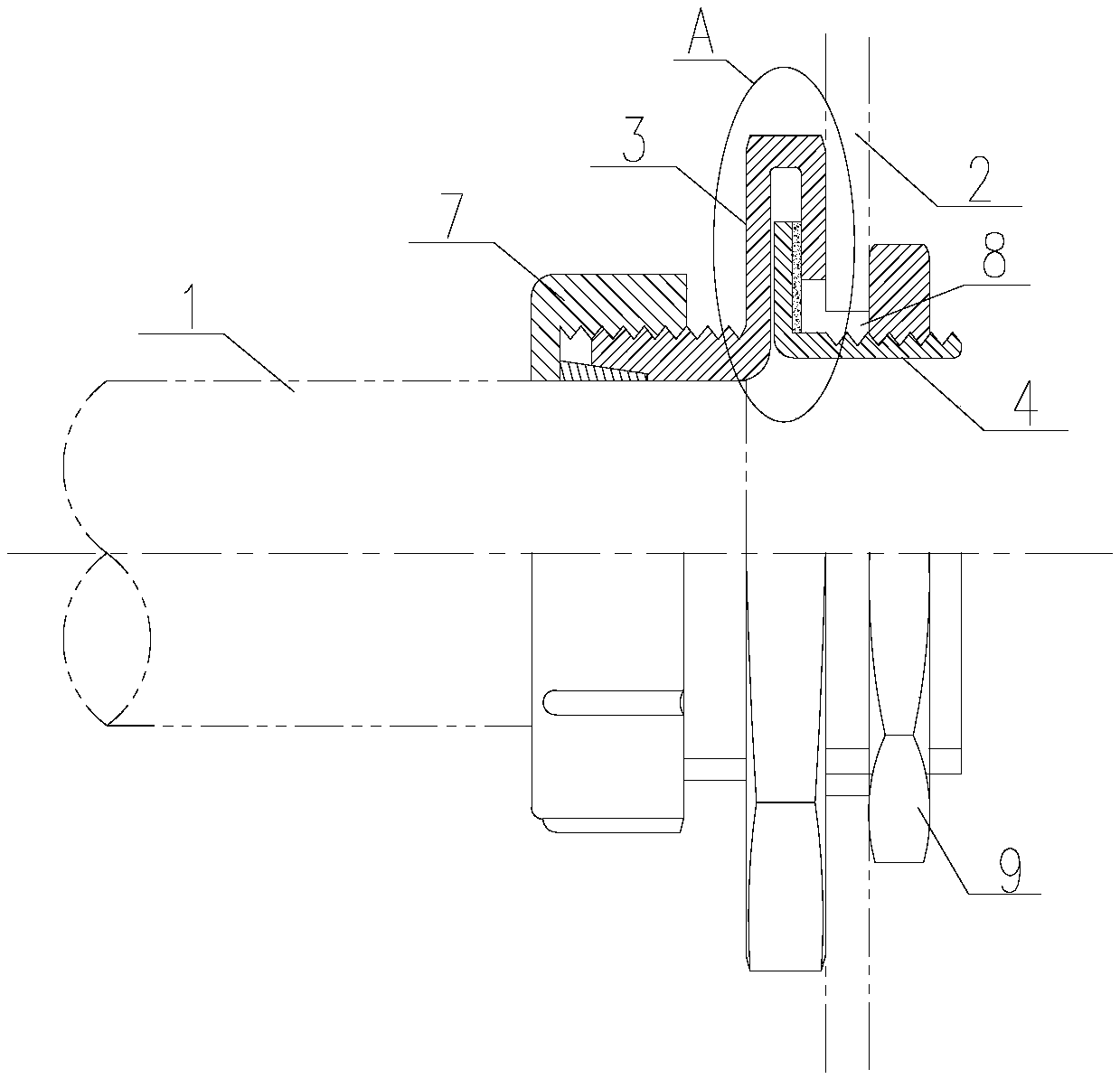

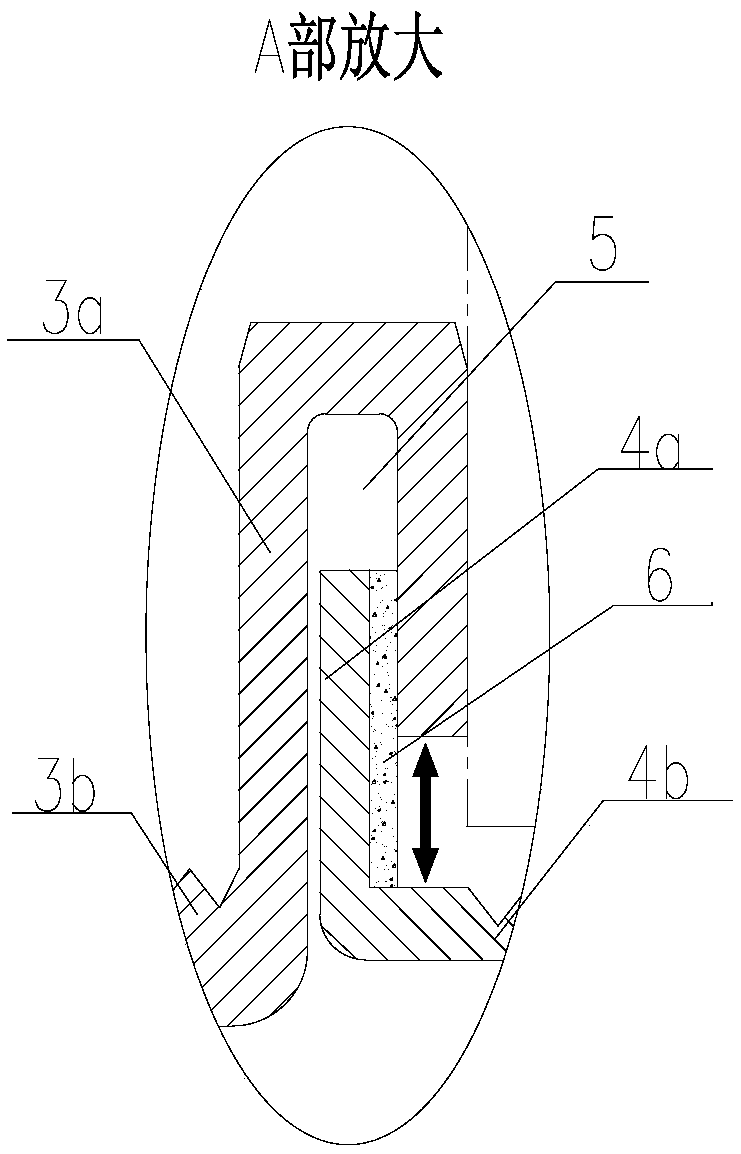

[0022] Such as Figure 1 to Figure 3 As shown, a floating butt joint provided by the present invention is used to connect piece one 1 and piece two 2. hole structure.

[0023] The joints include split joint one 3 and joint two 4 . Joint one 3 is composed of a head 3a and a tail 3b, and joint two 4 is also composed of a head 4a and a tail 4b. The tail portion 3b of joint one 3 is fixedly connected with piece one 1, the tail portion 4b of joint two 4 is fixedly connected with piece two 2, the head 3a of joint one 3 is connected with the head 4a of joint two 4, and then piece one 1 is connected with Pieces two 2 are connected together. Wherein, the head 3a of the first joint 3 and the head 4a of the second joint 4 are configured to be relatively radially floating, so that when there are manufacturing and installation errors between the first 1 and the second 2 to be connected , when the central axes of piece 1 and piece 2 are not on a straight line, the relative position in t...

Embodiment 2

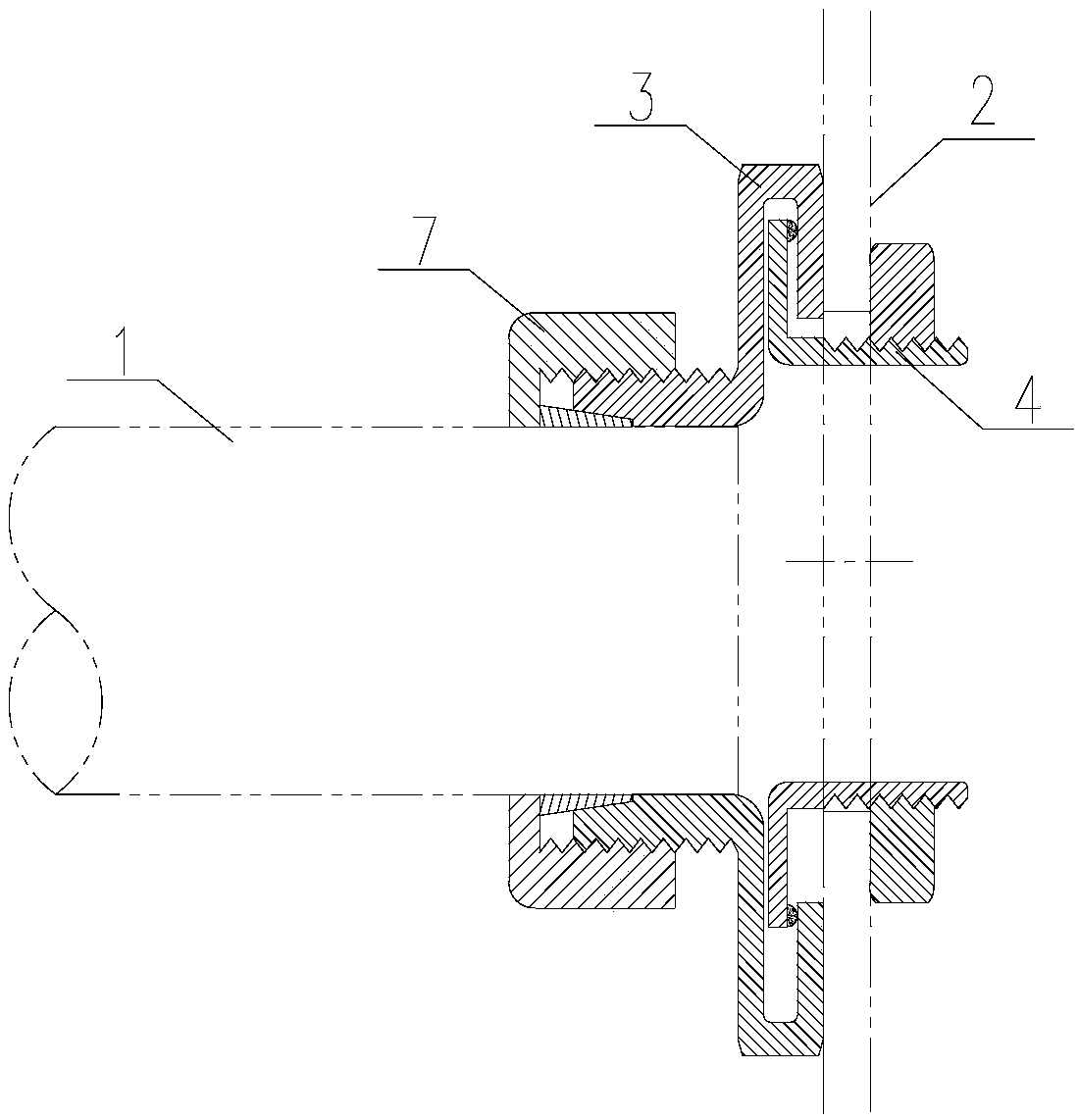

[0033] The difference from Embodiment 1 is that, as Figure 4 As shown, the first part 1 and the second part 2 in this embodiment are both electric wire pipes, and a nut 7 and a nut 7' are respectively sleeved on the front ends of the first part 1 and the second part 2, and are described in the first embodiment. The joint realizes the butt connection between the pipe and the pipe.

[0034] The working process is as follows: Figure 4 As shown, when the center line of part 2 (wire conduit) deviates from the center line of part 1 (wire pipe) due to manufacturing and installation errors, first screw the tail 4b of joint 2 4 and nut 7' into the part The end of the second 2 is tightened and fixed by the external thread on the tail 4b and the nut 7', adjust the relative position of the head 4a of the joint 2 4 and the head 3a of the joint 1 3, and insert the pipe end of the joint 1 1 into the joint In the tail part 3b of one 3, finally tighten the nut 7 installed on part one 1, an...

Embodiment 3

[0036] The difference from the first embodiment is that the head 3a of the first joint 3 has an integrated structure, and an internal spline groove (not shown in the figure) is provided on one side of its opening. Correspondingly, at the head of the second joint 4 4a is provided with an external spline protrusion. When installing, it is only necessary to insert the external spline protrusion of the joint 2 head 4a into the internal spline groove of the joint 1 head 3a, and then adjust the relative position of joint 1 3 and joint 2 4 , and then rotate and clamp, the connection between joint one 3 and joint two 4 can be realized, and this structure can be used to connect joint one 3 and joint two 4 when the vehicle is assembled.

[0037] The floating butt joint provided by the present invention, through the arrangement of joint one 3 and joint two 4 that can float relative to each other in the radial direction, successfully solves the problems between pipes and pipes and between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com