A quick disassembly and assembly frame structure for platform structure support and its construction method

A technology of platform structure and disassembly frame, which is applied in the direction of building structure support, building structure support, building structure, etc., which can solve the problems of low production cost, uncontrollable bearing capacity and stability, poor height and horizontal position adjustment accuracy, etc. problem, to achieve the effect of good integrity, convenient and flexible combination operation, and flexible height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

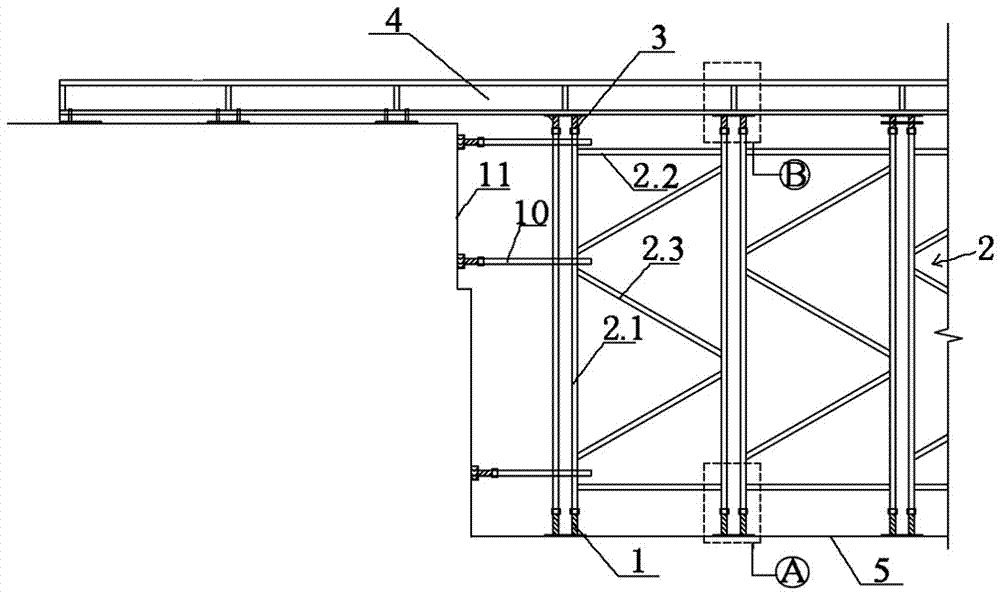

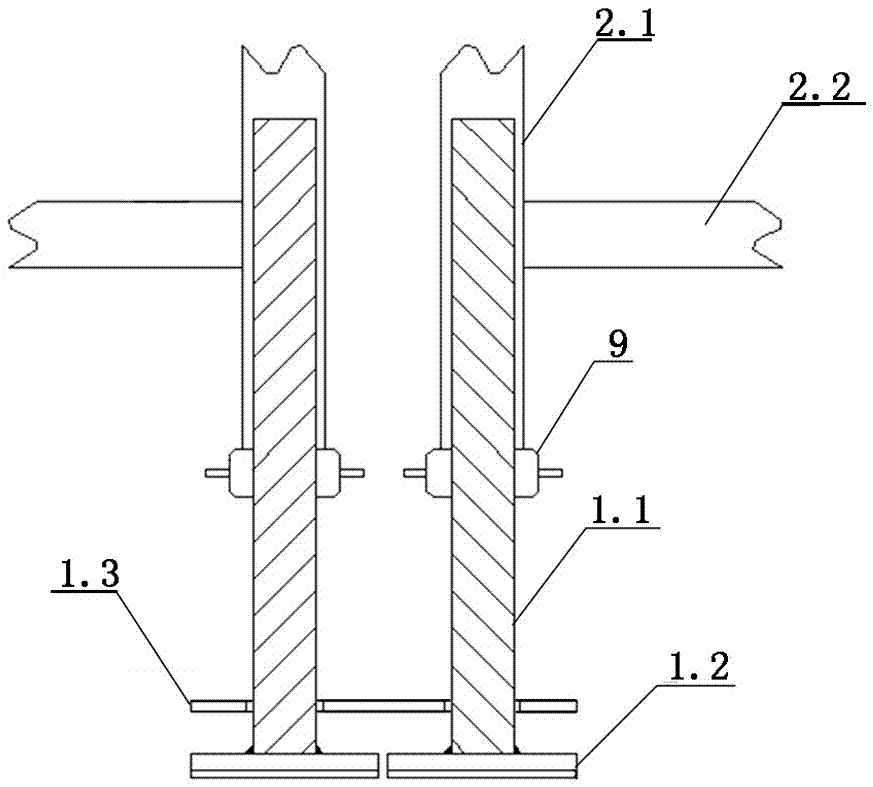

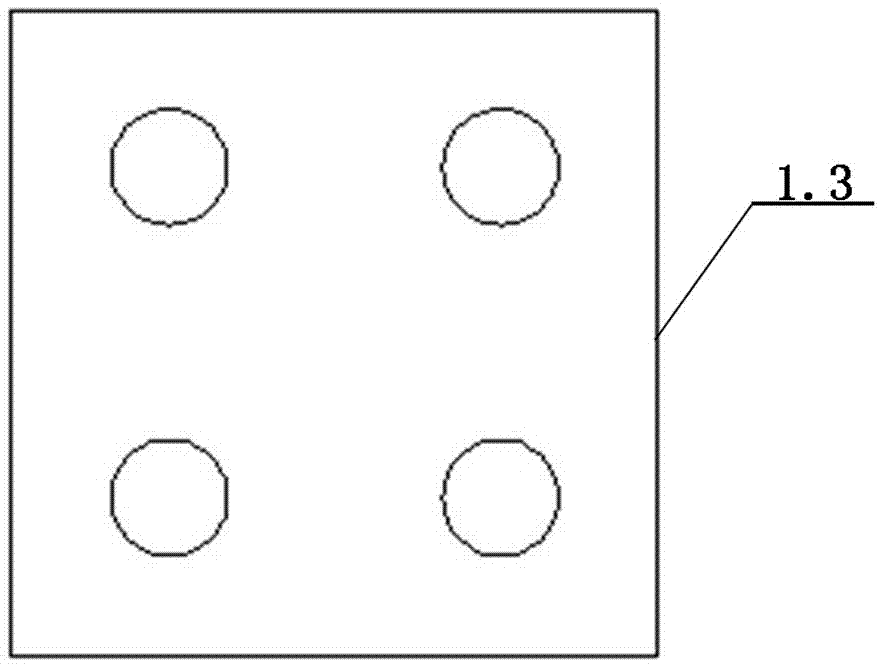

[0040] The present invention relates to a quick disassembly and assembly frame structure used for platform structure support, which is supported on the bottom of platform structure 4, and is characterized in that: figure 1 As shown, it includes an adjustment screw base 1, a scaffolding 2 and a top combination connector 3 from bottom to top; wherein, the adjustment screw base 1 is set on the bottom plane 5, including a square bottom plate 1.2 horizontally arranged at the bottom and a vertical Four lead screws 1.1 welded on the upper surface of the square bottom plate, the four lead screws 1.1 are arranged in a rectangle; the scaffold 2 is a tool-type scaffold, including a vertical rod 2.1 and a horizontal rod 2.2 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com