Container module building of integrated plane conversion framework

A plane conversion and container technology, which is applied to buildings, small buildings, building types, etc., can solve the problems of inability to align bolts and difficult on-site installation, achieve uniform and reasonable stress, improve construction efficiency, and reduce assembly difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

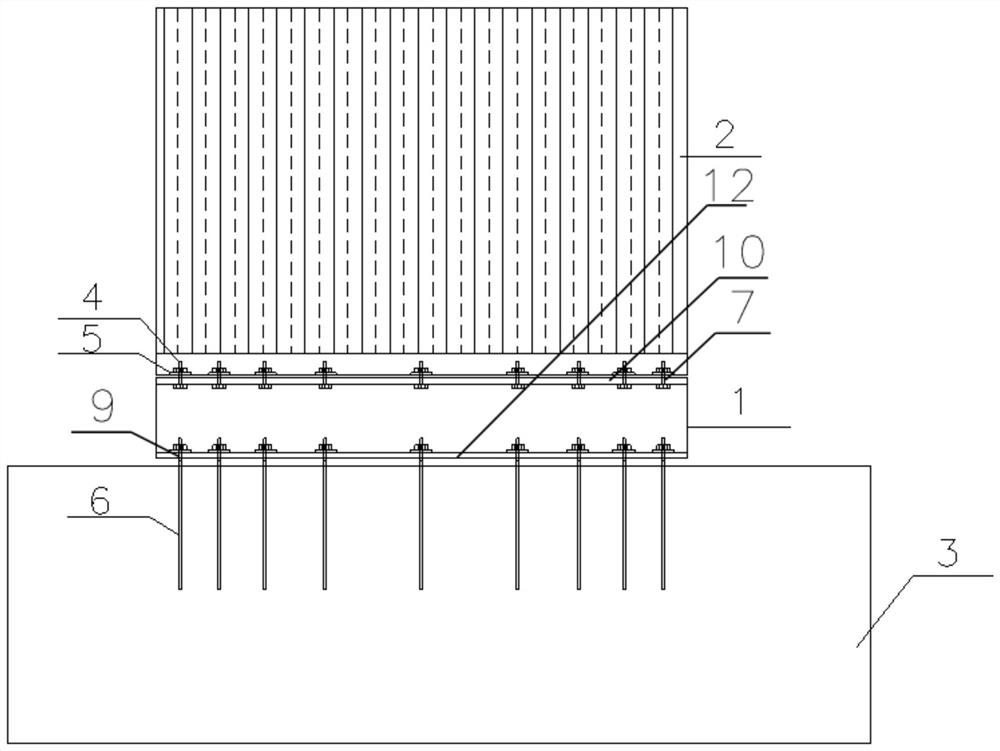

[0029] A container module building with an integrated plane conversion frame, the container module building is fixed on the building foundation 3, the foundation bolts 6 are fixed on the building foundation 3, the bottom of the container module building is fixedly connected with the plane conversion frame 1, and the plane conversion frame 1 passes through The foundation bolt 6 is fixedly connected with the building foundation.

[0030] Such as figure 1 As shown, in this embodiment, the foundation anchor bolt 6 is pre-embedded in the building foundation 3 , and the top end of the foundation anchor bolt 6 protrudes upward from the building foundation 3 .

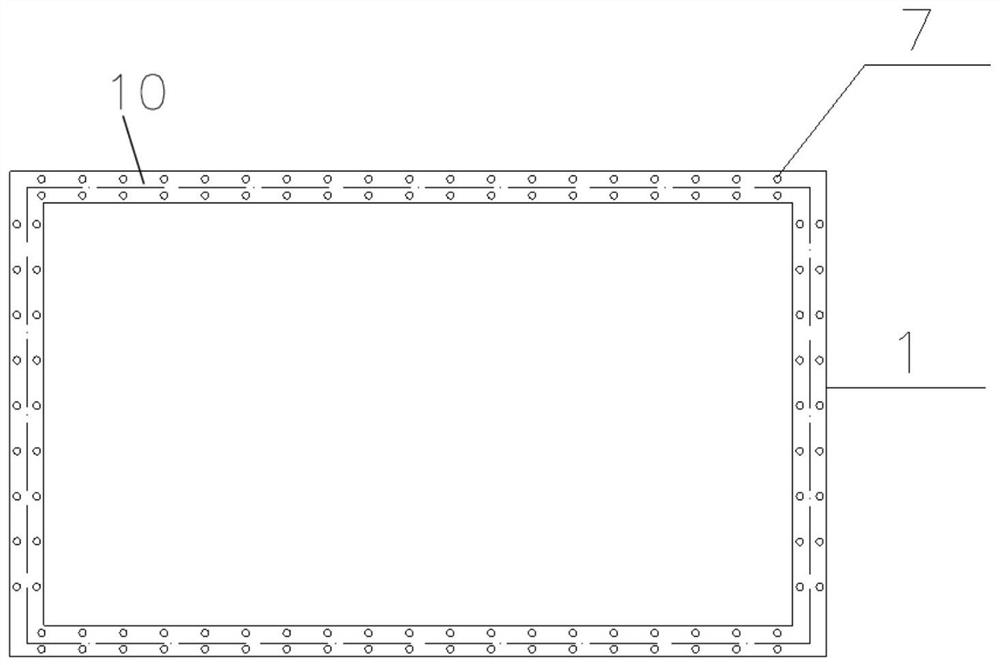

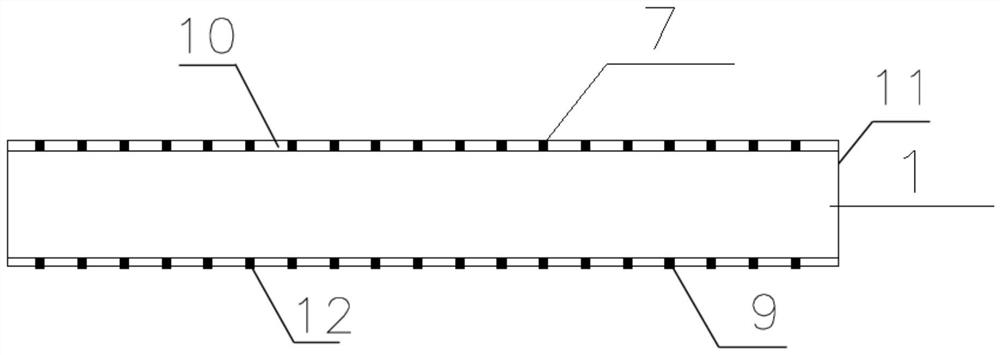

[0031] Such as Figure 2-4 As shown, specifically, the container module building includes a cuboid building body 2 and a plane conversion frame 1, the bottom plate of the building body 2 is provided with bottom plate connecting screw holes, and the plane conversion frame 1 includes metal thick gaskets 5, connecting bolts 4, ...

Embodiment 2

[0039] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the building foundation 3 includes a foundation body and a plurality of overhead frames 8, and a plurality of overhead frames 8 are fixed on the foundation body at intervals to form an overhead groove, and the overhead frame body 8 includes an overhead roof , the overhead support plate and the overhead bottom plate, the top of the overhead support plate is fixedly connected with the overhead roof plate, the foundation bolt 6 is fixed on the overhead roof plate, the foundation bolt 6 passes through the lower screw hole 9 and the metal thick washer 5 and is screwed with the nut, and fixed The overhead frame connecting the foundation connecting plate 12 and the building foundation 3 .

[0040] Specifically, the overhead roof plate, the overhead support plate and the overhead floor plate are all steel plates, the top of the overhead support plate is welded to the overhead roof plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com