A virtual synchronous power generation system

A technology of virtual synchronous power generation and cooler, which is applied to electromechanical devices, electrical components, electric components, etc., can solve the problem of reducing the service life of the virtual synchronous power generation system, the operation efficiency of the virtual synchronous power generation system is easily affected by its temperature, and the virtual synchronous power generation system. Reduce system operating efficiency and other problems to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

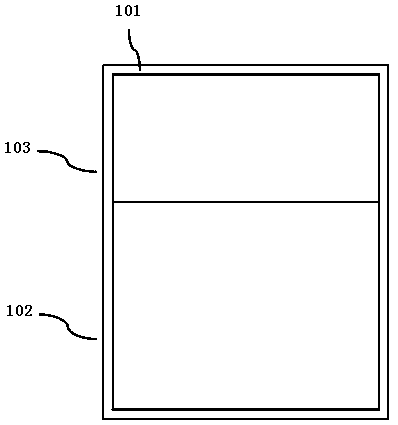

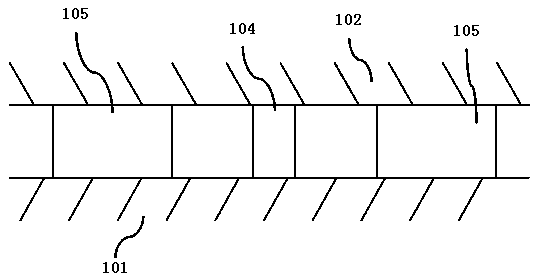

[0022] Such as Figure 1-4 As shown, the virtual synchronous power generation system of the present invention includes a virtual synchronous power generation unit 102 , a casing 101 , a power supply, and a cooler 103 . The power source of the virtual synchronous power generation system is connected to the virtual synchronous power generation unit 102 and the cooler 103 , and the power source is used to provide electric energy to the virtual synchronous power generation unit 102 and the cooler 103 . The virtual synchronous power generation unit 102 , the power supply and the cooler 103 are all arranged in the casing 101 . The cooler 103 is attached to at least a part of the virtual synchronous power generation unit 102 , and the cooler 103 is used for cooling the virtual synchronous power generation unit 102 .

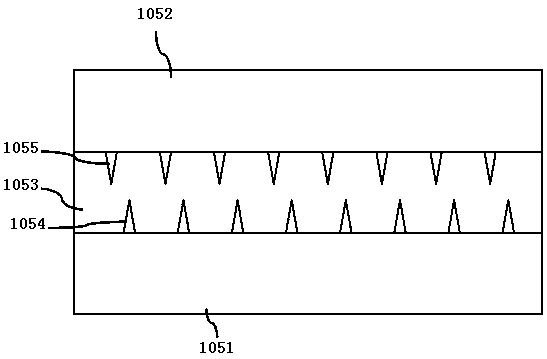

[0023] The cooler 103 includes a control unit, a heat collecting plate, a running part, a cooler body, a bearing shaft, a coolant supply unit, a coolant delivery pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com