Cross-type counterweight energy-saving quay crane double-trolley steel wire rope winding system

A steel wire rope and counterweight technology, which is applied to the cranes, hoists, and hoisting devices of trolleys, can solve the problems of complex wire rope winding systems and difficult layout, improve container loading and unloading efficiency, avoid mutual interference between wire ropes, and improve structural stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

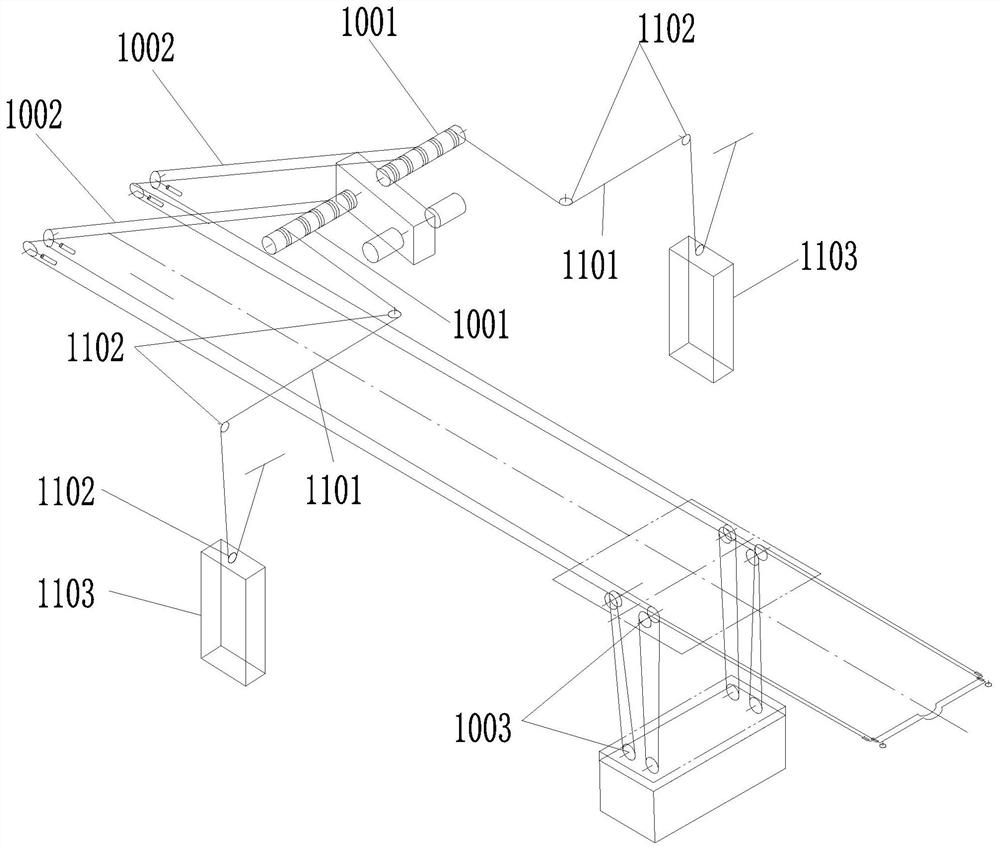

[0026] Embodiment 1 of the present invention: as figure 1 As shown, this embodiment is a double-trolley steel wire rope winding system for a cross-counter balance weight energy-saving quay bridge, including an energy-saving winding system for the upper trolley, an energy-saving winding system for the lower trolley, a lifting and winding system for the upper trolley, a lifting and winding system for the lower trolley, and an upper and lower trolley winding system. Trolley walking winding system, lower trolley walking winding system, upper trolley energy-saving counterweight 1 and lower trolley energy-saving counterweight 2.

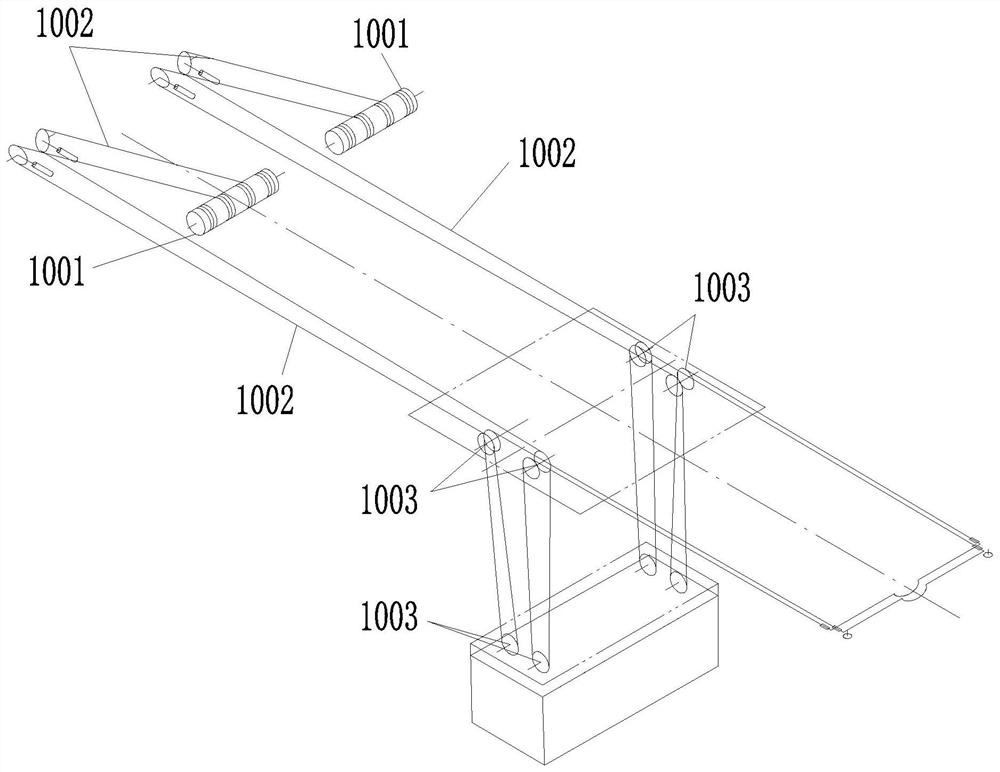

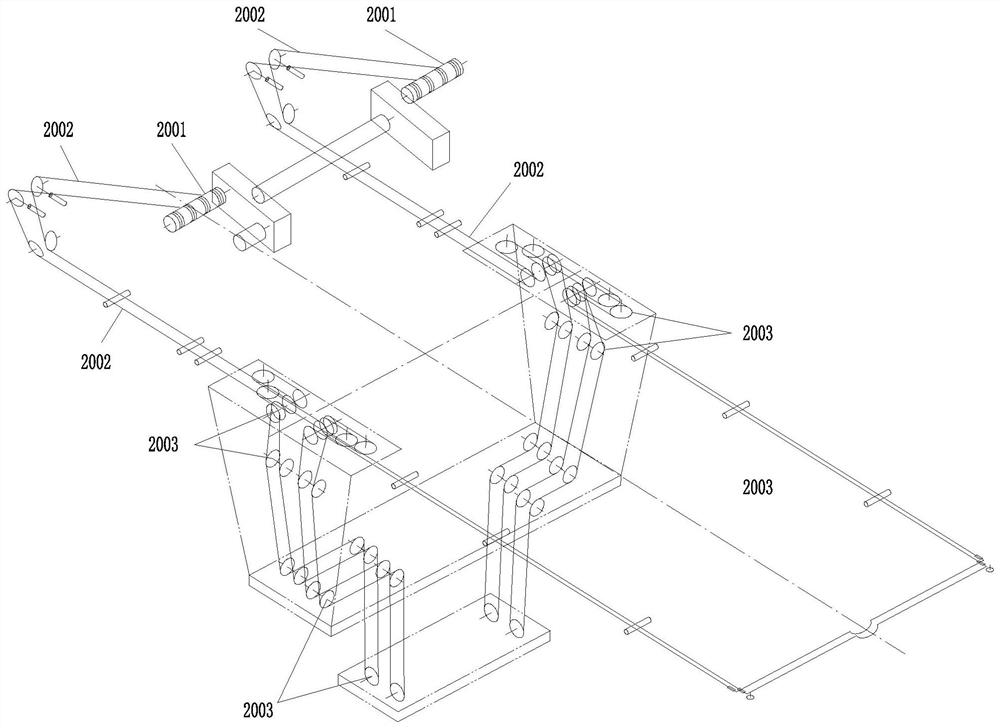

[0027] Such as figure 2 and Figure 4 As shown, the upper trolley lifting winding system described in this embodiment includes the upper trolley lifting reel 1001 and the upper trolley lifting steel wire rope 1002 wound on the upper trolley lifting reel 1001, the upper trolley energy-saving winding system includes winding The upper trolley energy-saving...

Embodiment 2

[0035] Embodiment 2 of the present invention: as figure 1 As shown, this embodiment is a double-trolley steel wire rope winding system for a cross-counter balance weight energy-saving quay bridge, including an energy-saving winding system for the upper trolley, an energy-saving winding system for the lower trolley, a lifting and winding system for the upper trolley, a lifting and winding system for the lower trolley, and an upper and lower trolley winding system. Trolley walking winding system, lower trolley walking winding system, upper trolley energy-saving counterweight 1 and lower trolley energy-saving counterweight 2.

[0036] Such as figure 2 and Figure 4 As shown, the upper trolley lifting winding system described in this embodiment includes the upper trolley lifting reel 1001 and the upper trolley lifting steel wire rope 1002 wound on the upper trolley lifting reel 1001, the upper trolley energy-saving winding system includes winding The upper trolley energy-saving...

Embodiment 3

[0046] Embodiment 3 of the present invention: as figure 1 As shown, this embodiment is a double-trolley steel wire rope winding system for a cross-counter balance weight energy-saving quay bridge, including an energy-saving winding system for the upper trolley, an energy-saving winding system for the lower trolley, a lifting and winding system for the upper trolley, a lifting and winding system for the lower trolley, and an upper and lower trolley winding system. Trolley walking winding system, lower trolley walking winding system, upper trolley energy-saving counterweight 1 and lower trolley energy-saving counterweight 2.

[0047] Such as figure 2 and Figure 4 As shown, the upper trolley lifting winding system described in this embodiment includes the upper trolley lifting reel 1001 and the upper trolley lifting steel wire rope 1002 wound on the upper trolley lifting reel 1001, the upper trolley energy-saving winding system includes winding The upper trolley energy-saving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com