Rotor core and steam turbine generator with rotor core

A steam turbine generator and rotor core technology, which is applied to machines/engines, electrical components, electromechanical devices, etc., can solve problems affecting work efficiency, operation safety, magnetic circuit loss, and aging of rotor core surface insulation, so as to improve heat dissipation capacity. And the effect of heat dissipation uniformity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

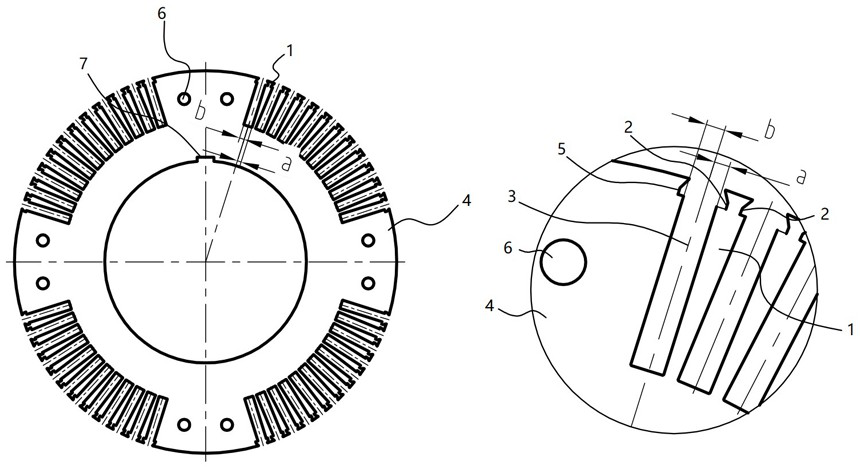

[0013] A rotor core, such as figure 2 As shown, it includes a plurality of rotor punches 1 arranged at intervals, the two opposite side walls on the free end side of the rotor punches 1 are respectively provided with first grooves 2, and two adjacent rotor punches 1 The distance between the center line 3 between the side walls of the opposite first groove body 2 is a from the side wall of the rotor punch 1 on one side, and the distance from the side wall of the rotor punch 1 on the other side is b, and b>a or b figure 2 As shown, the distance between the center line 3 between the opposite side walls of the first slot body 2 on two adjacent rotor punches 1 is c from the side wall of the first slot body 2 . Wherein, the values of a and b are calculated and determined according to the actual magnetic circuit, and the calculation method is the prior art.

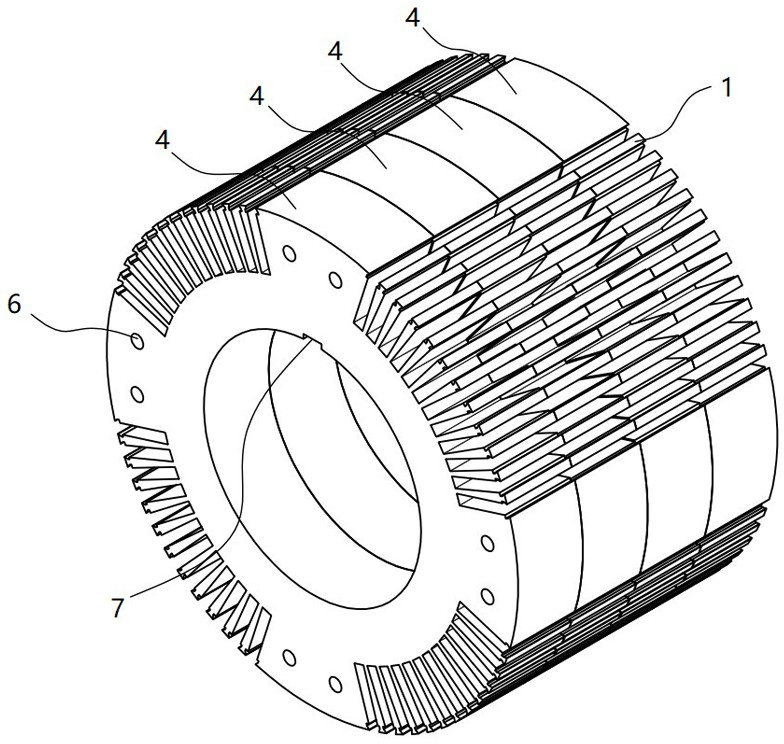

[0014] The rotor core 4 includes a ring-shaped body on which a plurality of sets of rotor punching sets are arranged at in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com