Campus plant landscape cultivation device

A cultivation device and plant technology, applied in the field of campus plant landscape cultivation devices, can solve the problems of wasting manpower, increasing labor load, and low efficiency, and achieve the effects of reducing labor costs, improving work efficiency, and flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

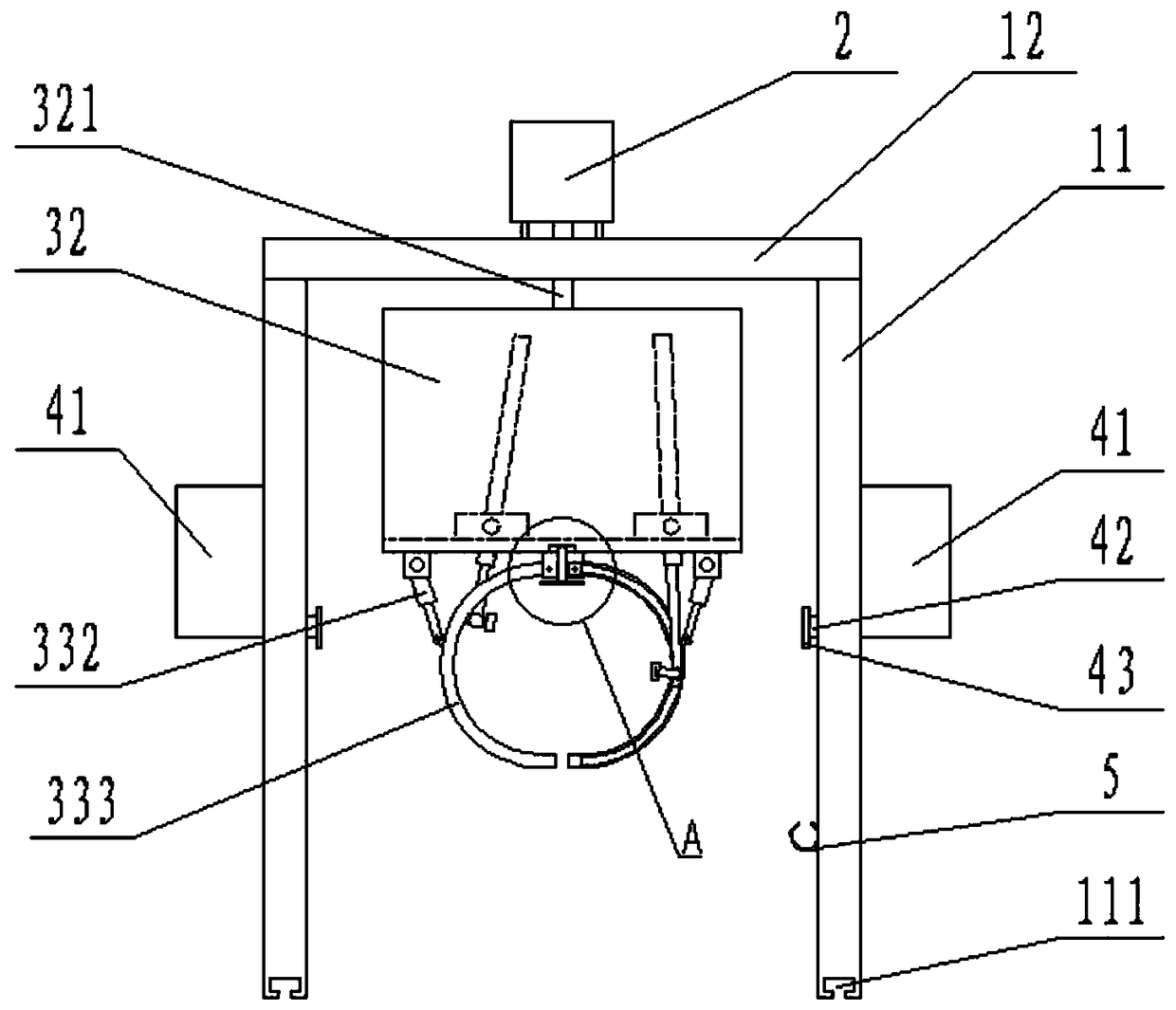

[0024] as attached figure 1 To attach Figure 5 As shown, it includes a mobile frame, a motor 2, a pruning device and a controller. The mobile frame includes four vertically arranged pillars 11 and a horizontally arranged top plate 12. The height of the pillar 11 is greater than the maximum height of the plant landscape, ensuring that the The pruning device can work normally, and the upper end of the pillar 11 is fixed with the top plate 12 by welding. In order to facilitate the movement of the entire cultivation device, slide rails are preset on both sides of the plant landscape, and a slide groove 111 corresponding to the slide rails is opened at the lower end of each pillar 11 .

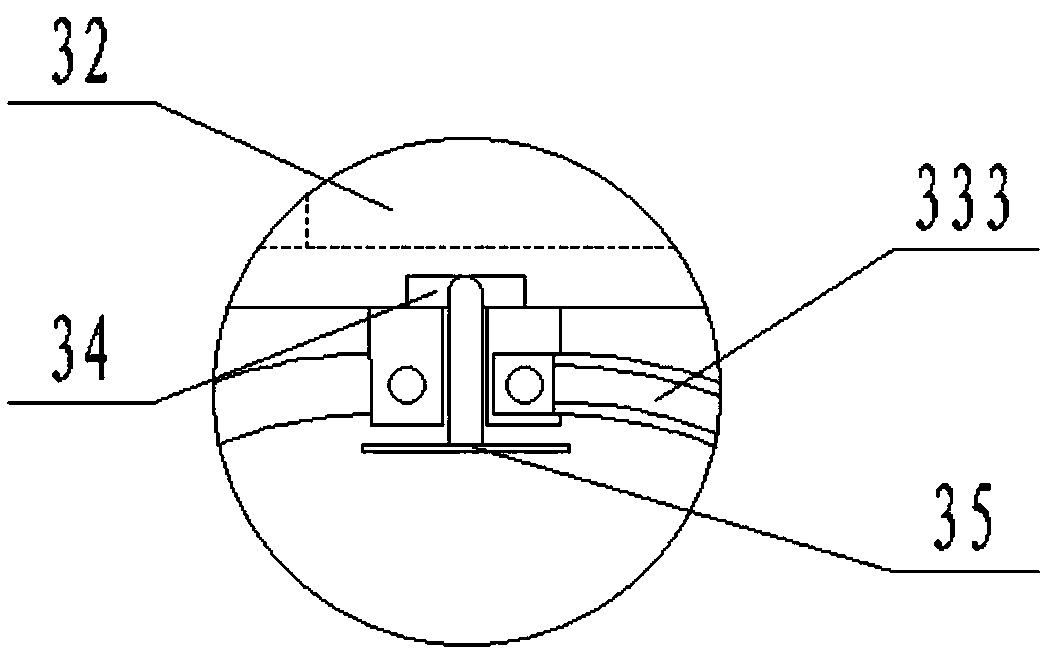

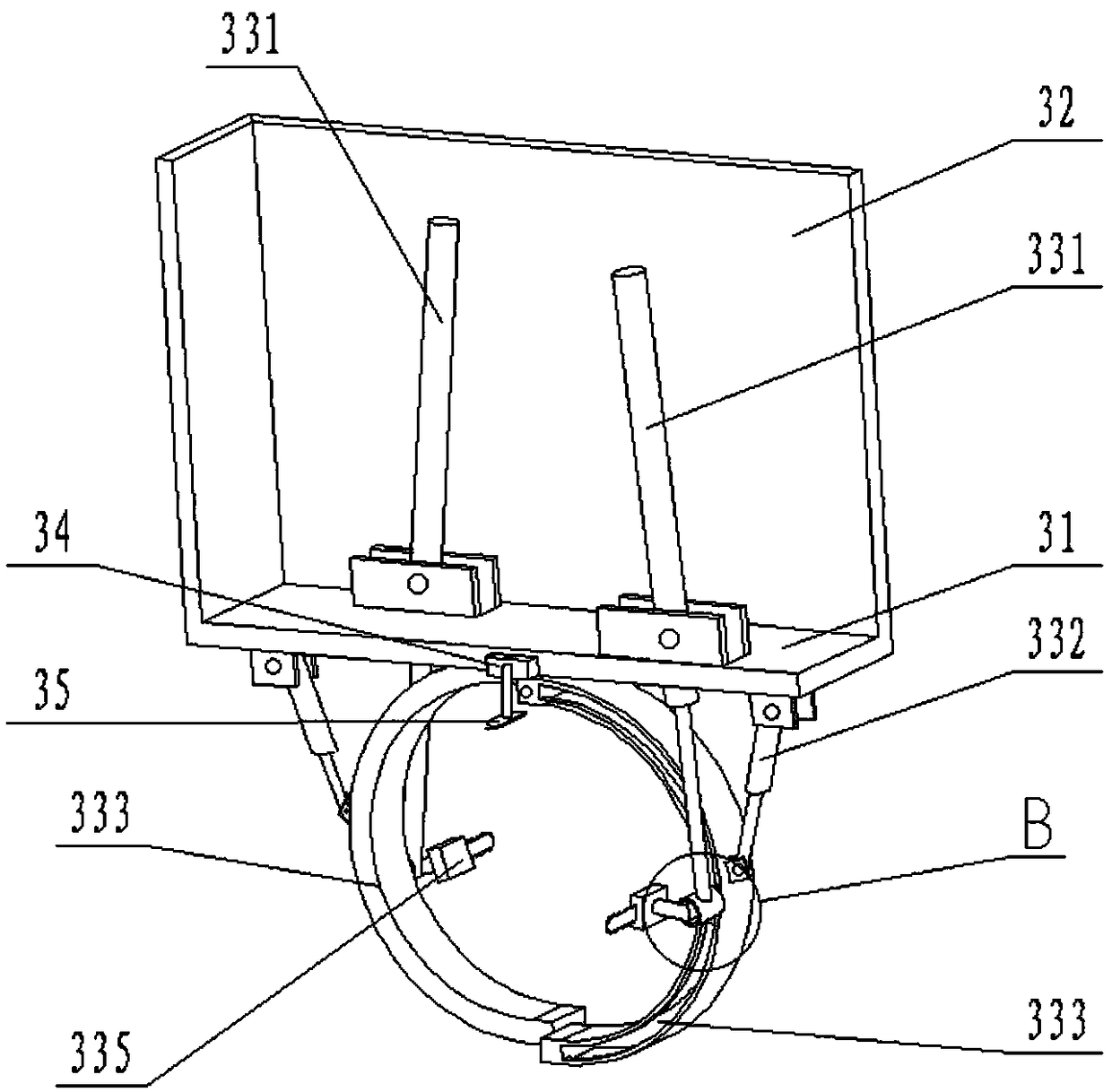

[0025] Trimming device comprises base plate 31, casing 32 and pruning mechanism, casing 32 lower ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com