Alignment method for turnover boring

A technology of boring and positive blocks, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems that the turning-back boring cannot meet the requirements, and the processing coaxial error is too large, etc., to achieve Solve the coaxial problem of U-turn boring, good practicability, and clear design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

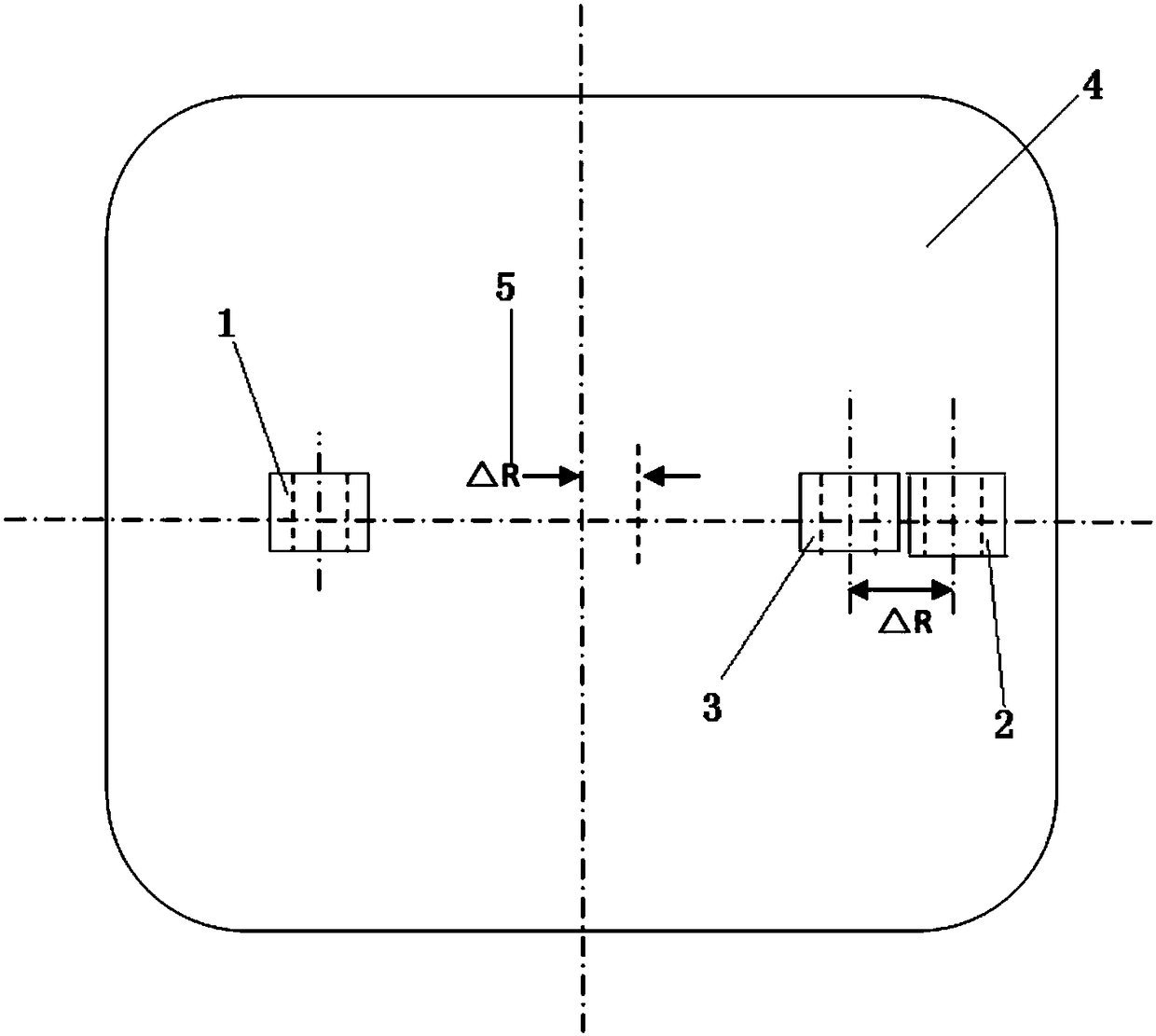

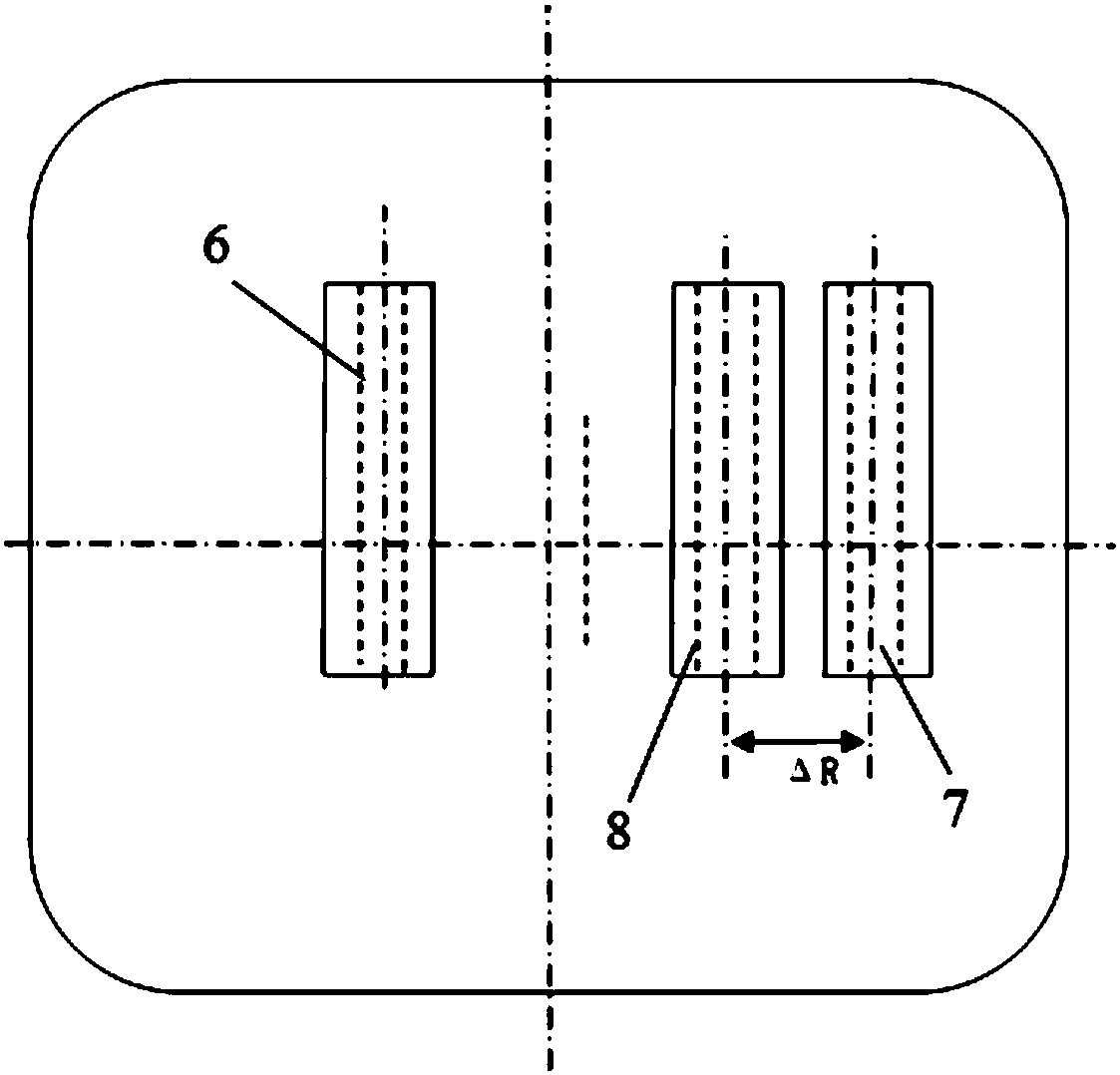

[0023] Example: A certain type of housing has a Φ25 through hole and a length of 323mm. Use a Φ26 standard hole with a length of 100mm for alignment, use a dial indicator to straighten the through hole on the standard alignment block 1 to 0.002mm, and the center error of the through hole of the standard alignment block 1 for alignment is 0.002mm, eliminating the machine tool table rotation 180 °Finally, for the alignment error of the through hole on the standard alignment block 1, set the horizontal coordinate of the through hole center of the alignment block 1 to 0, and use this coordinate as the theoretical horizontal coordinate. The machine tool table rotates 180° to drive the standard aligning block 1 to turn around to the actual position 3 of the standard aligning block, and to align again the actual horizontal coordinate of the center of the through hole on the standard block 1 is +0.012mm, and the theoretical position 2 after the standard aligning block is turned around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com