Centering device for valve side sleeve of converter transformer

A converter transformer and centering device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of alignment accuracy, damage to bushings, and increased difficulty of assembly, and achieve the goal of improving alignment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

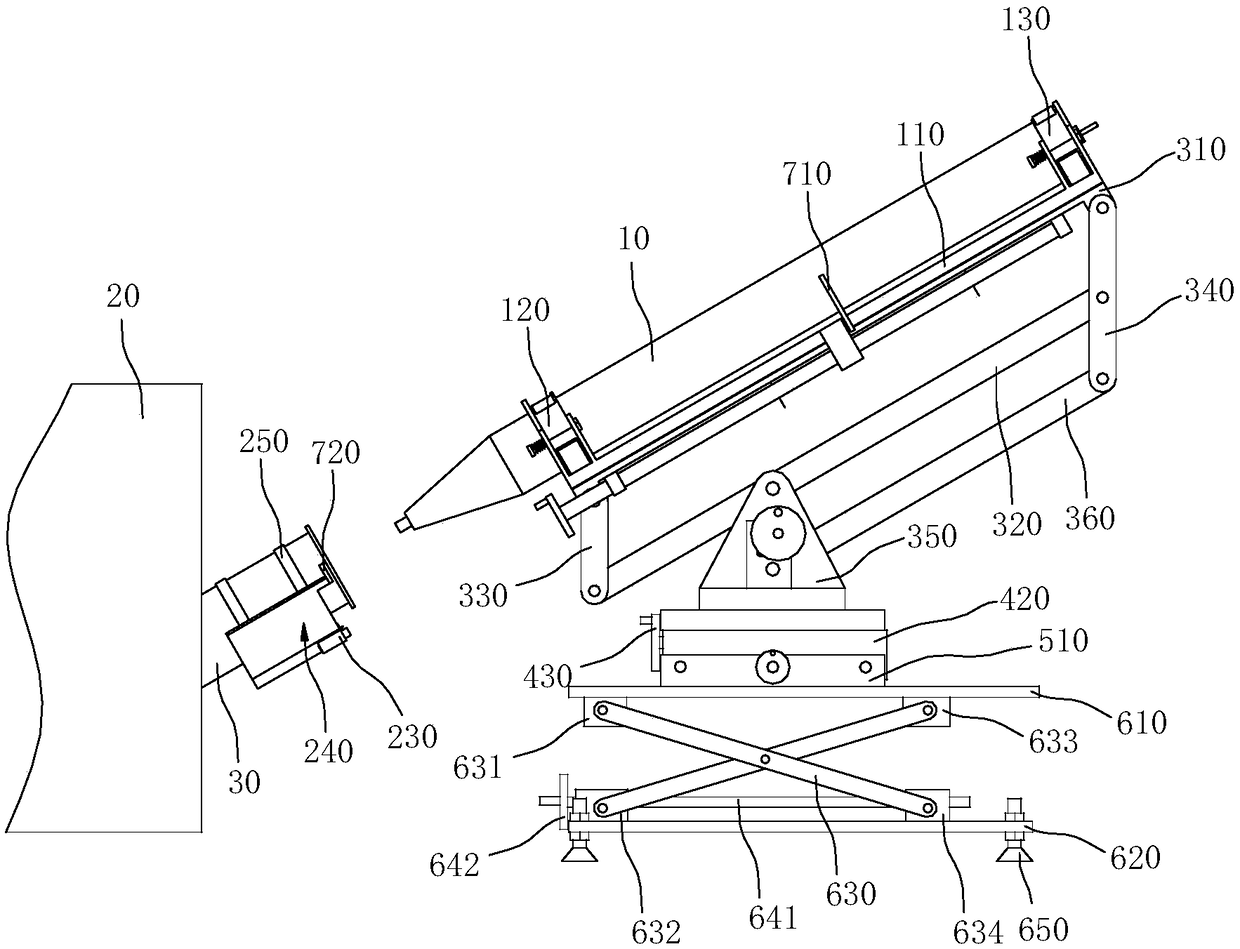

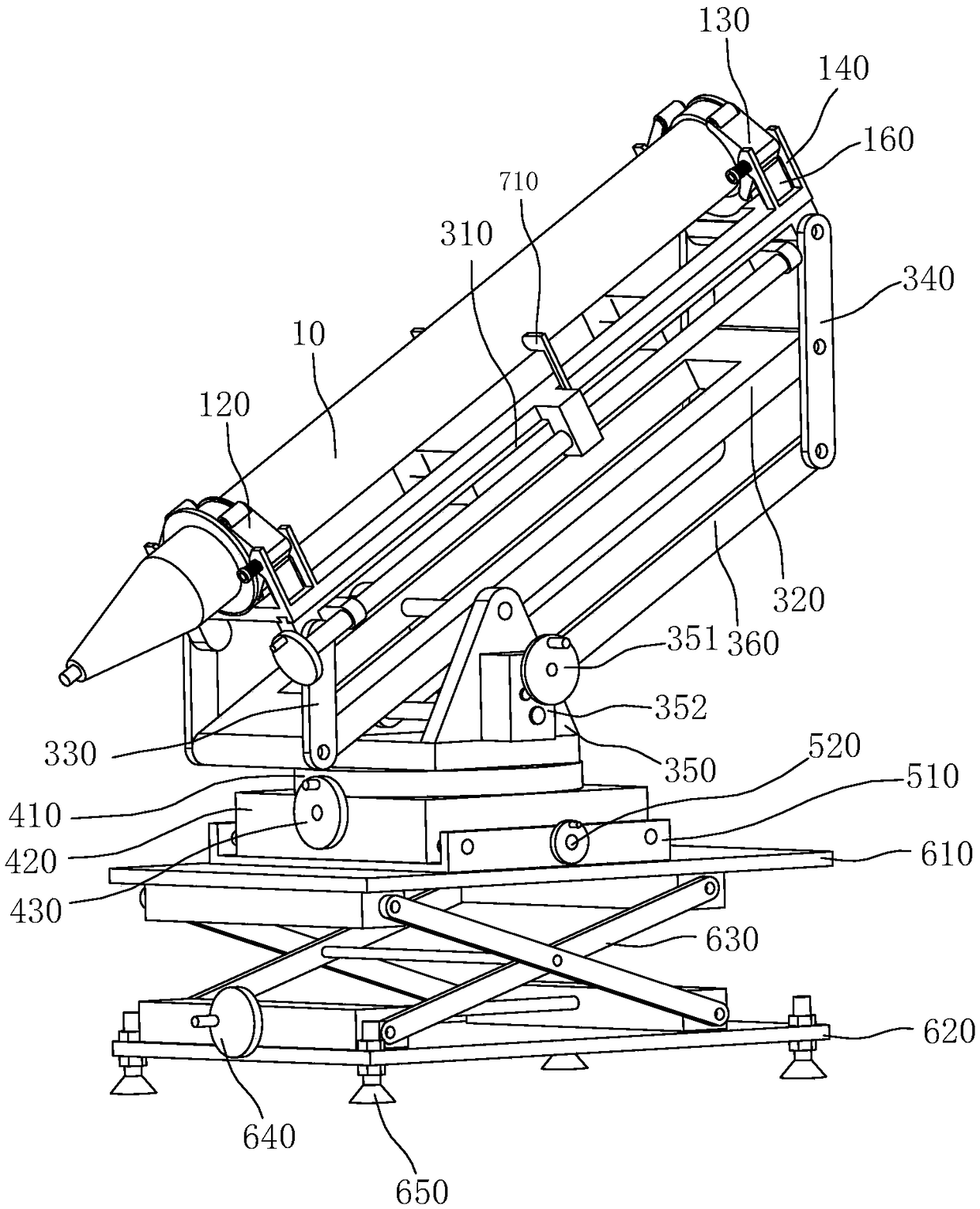

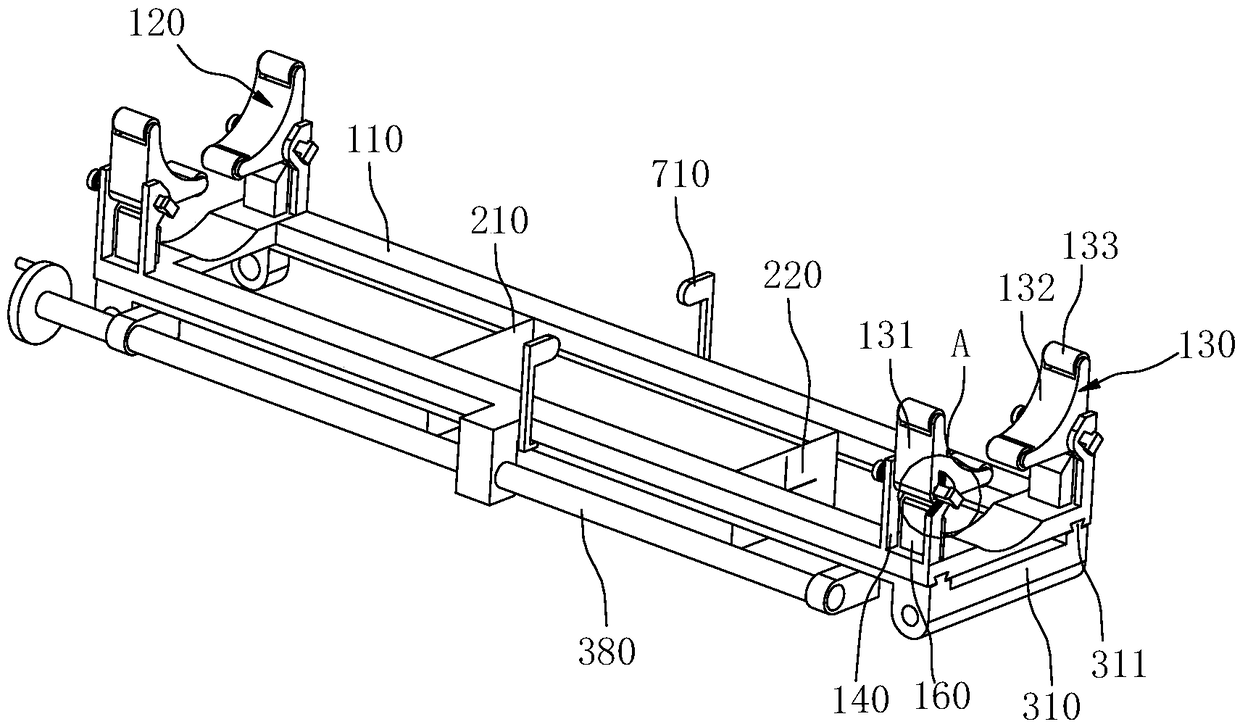

[0029] The following is attached Figure 1-19 Specific embodiments of the present invention will be described in detail.

[0030] A bushing installation device on the valve side of a converter transformer, comprising a clamping device for clamping and locking the bushing 10, the clamping device is connected with the adjusting device to realize the adjustment of the up and down, left and right, pitch and rotation positions of the bushing 10 , A centering device is provided between the bushing 10 and the outlet sleeve 30 on the converter transformer 20. After the bushing 10 and the outlet sleeve 30 are centered, the clamping device is driven by the power element to move toward the outlet sleeve 30, thereby The end of the sleeve 10 enters the outlet sleeve 30 to realize the docking between the two, and the separation of the sleeve 10 and the clamping device is realized by the unlocking device.

[0031] Such as figure 1 , 2 , 3, 4, and 5, the specific implementation of one of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com