Curved glass automatic film pasting equipment and film pasting method thereof

A technology for curved glass and film sticking equipment, which is applied in the field of automatic film sticking equipment for curved glass and its film sticking. It can solve the problems of unclean air bubbles, easy warping of tempered film, and easy falling off of tempered film, so as to improve precision and fit. The effect of tightness and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

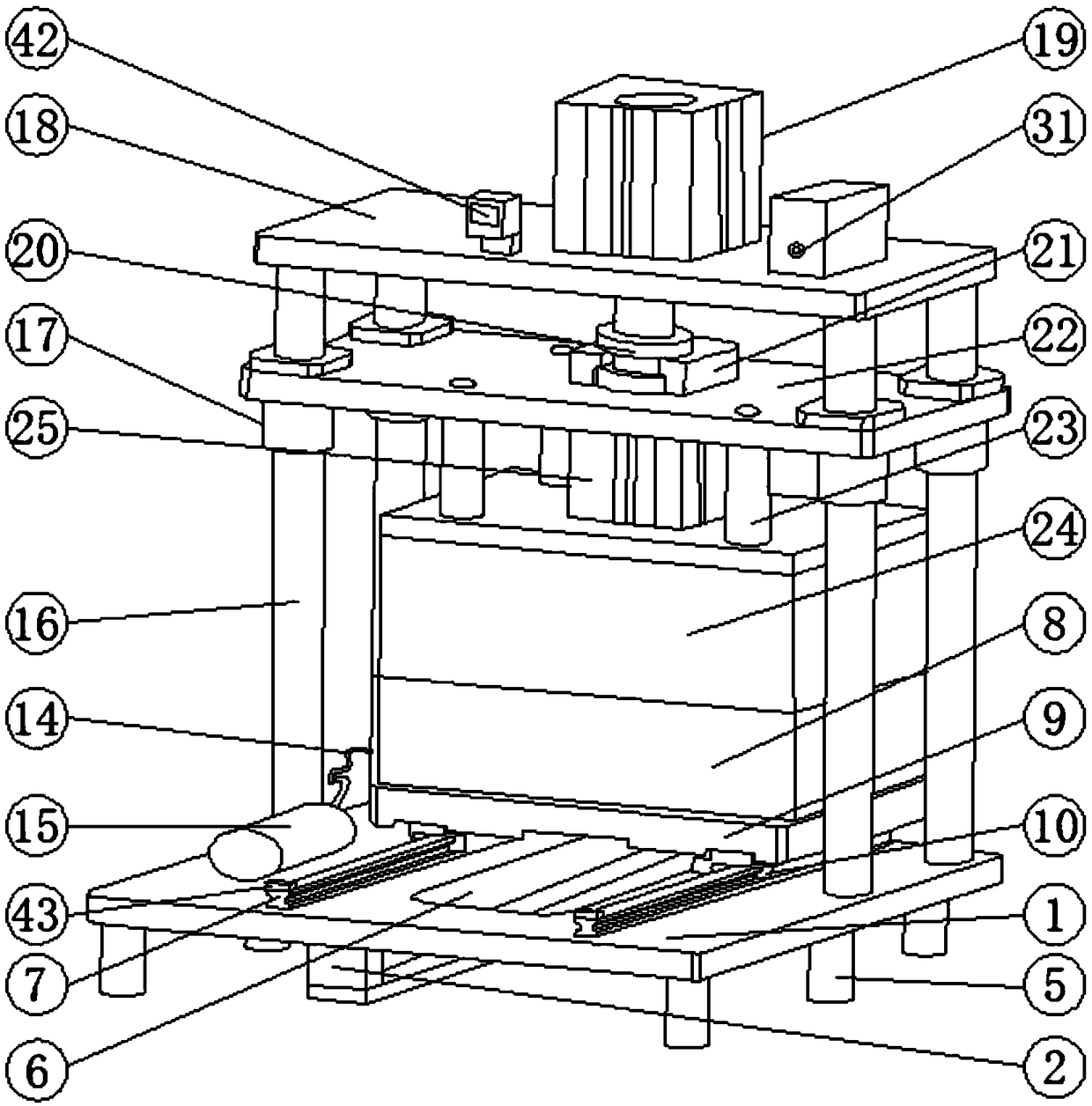

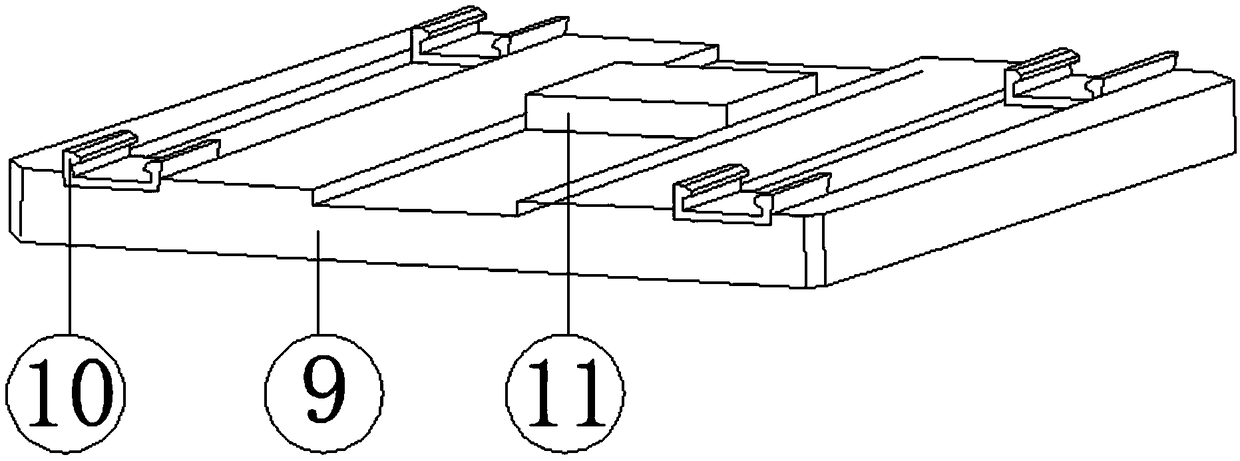

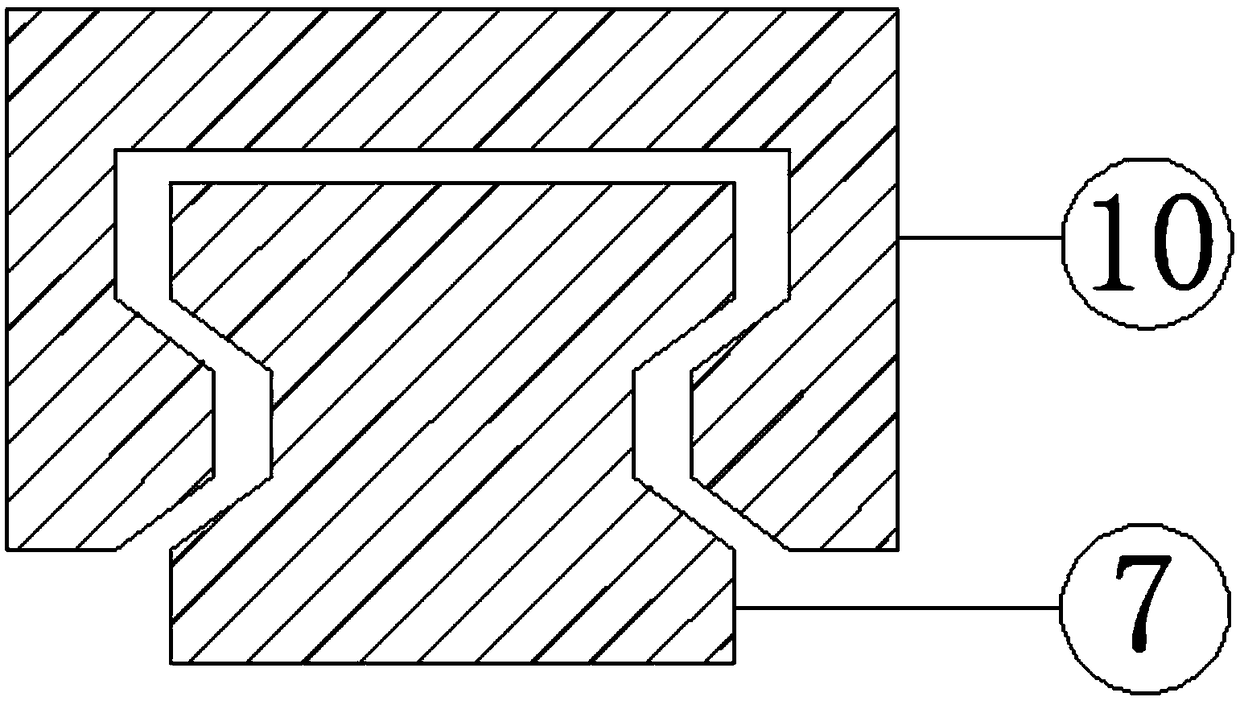

[0045] see Figure 1-11 According to an embodiment of the present invention, an automatic film-attaching device for curved glass includes a first base 1, a translation cylinder 2, a lower mold 13 module mechanism, an upper mold 28 module mechanism, an electric heating tube 4 and a pressing module mechanism, The transmission mechanism is located below the first base 1, the lower mold 13 module mechanism is located above the first base 1 and is movably connected with the first base 1 through a transmission mechanism, and the upper mold 28 module mechanism is located Above the module mechanism of the lower mold 13, the electric heating tube 4 is located in the module mechanism of the upper mold 28, the pressing module mechanism is located above the module mechanism of the upper mold 28, and the first base 1 is fixedly provided with six foot posts 5, and the middl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap