Variable-diameter positioning pin structure and multiple-vehicle-type rail trolley

A technology of positioning pins and trolleys, applied to conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of cost increase, inconvenient storage, waste of resources, etc., and achieve the effects of saving costs, facilitating storage, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

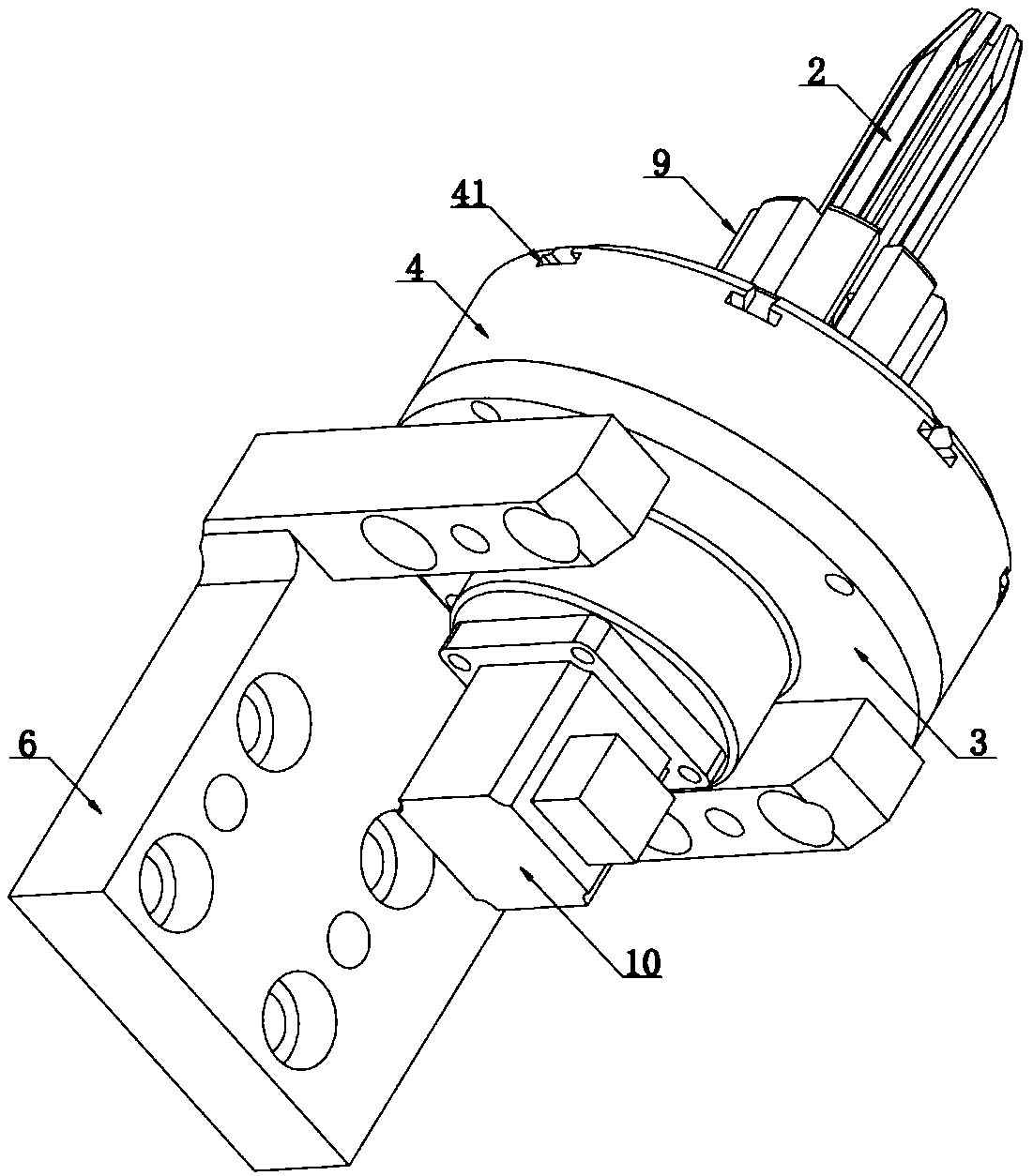

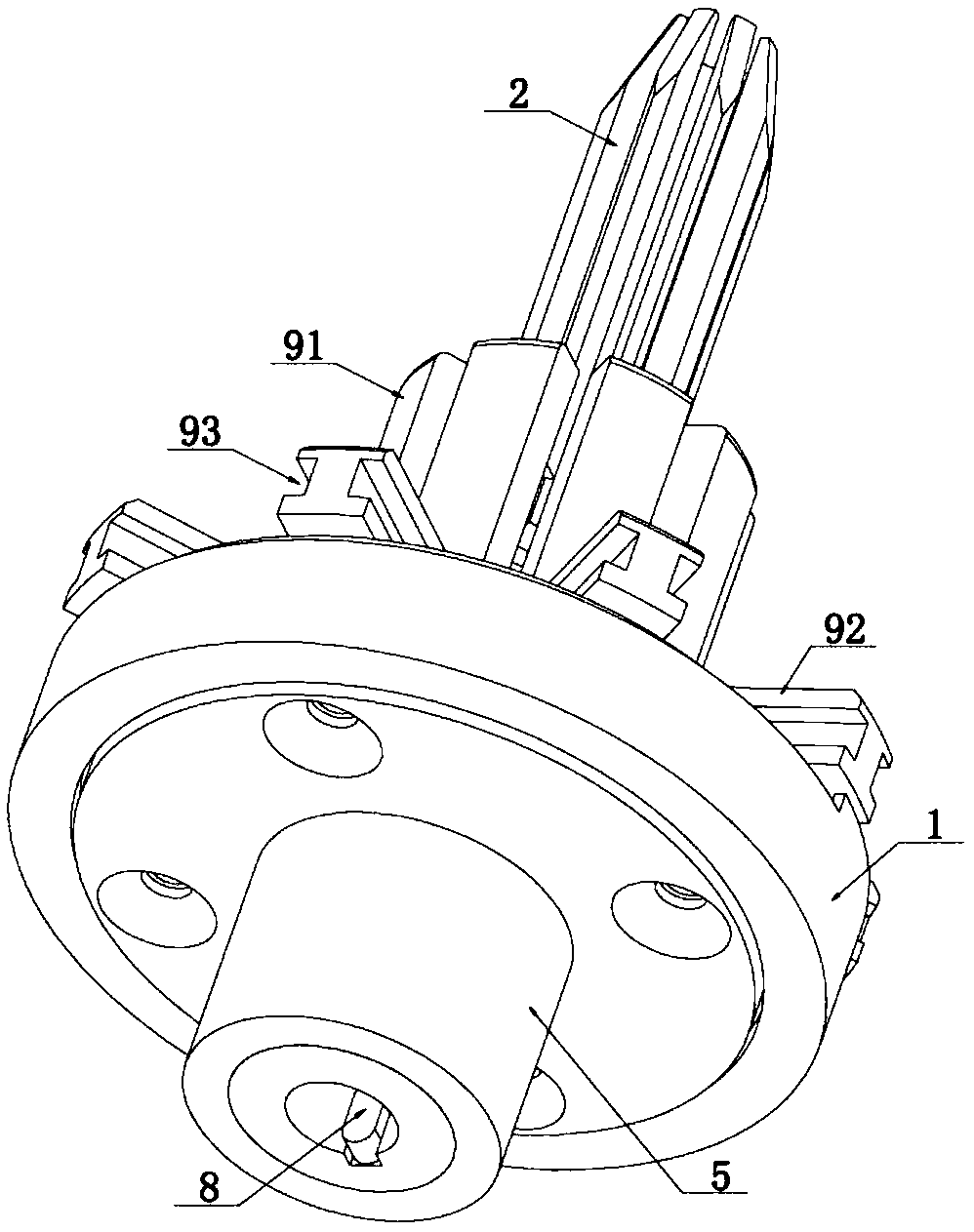

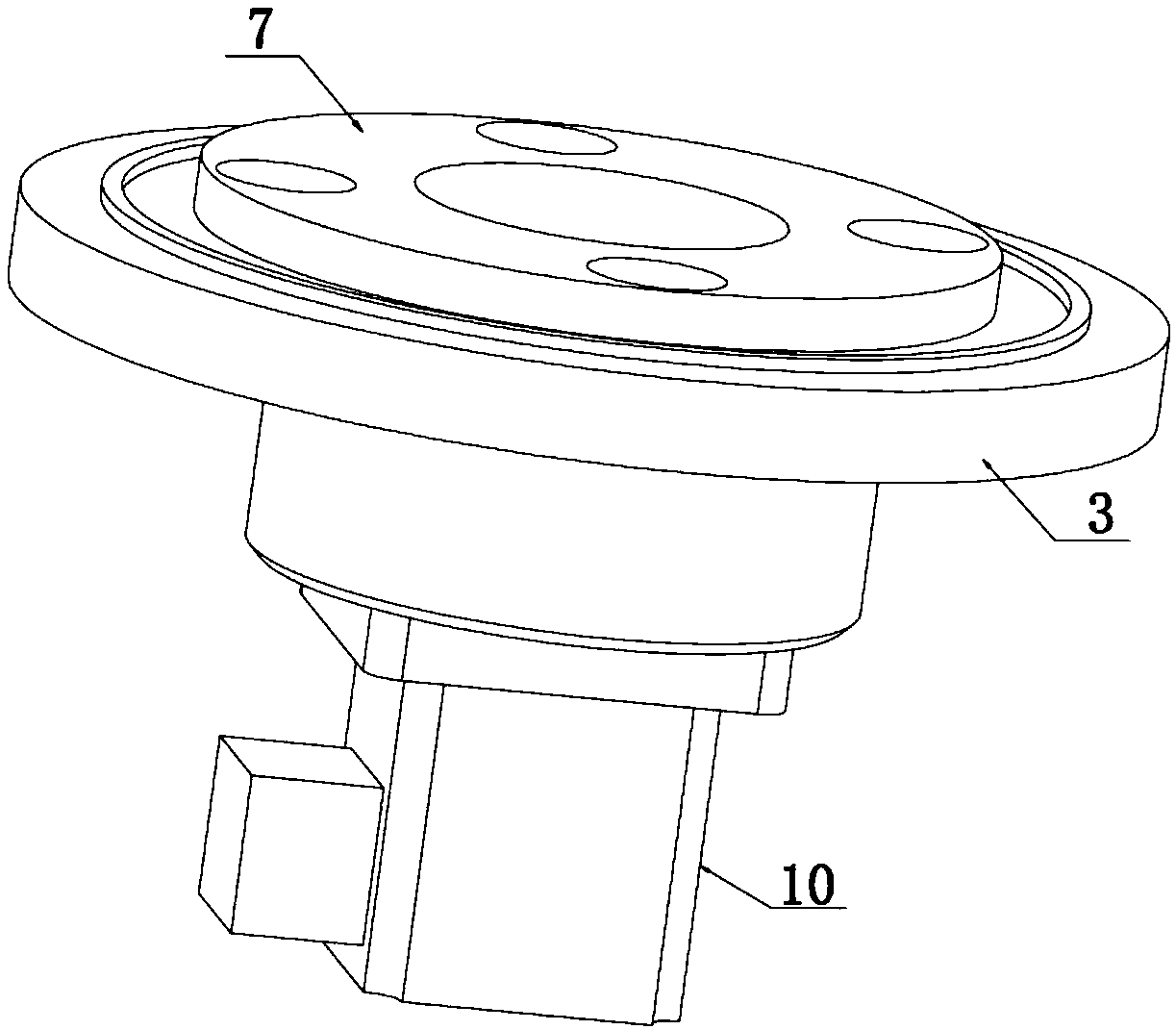

[0058] Such as Figure 1-Figure 9 As shown, a variable diameter positioning pin structure includes a mounting base 3, a turntable 1 arranged on the mounting base, a servo motor 10 for driving the turntable to rotate, a protective cover 4 and a plurality of pin claws 2, and the servo motor is installed On the mounting seat, a shaft hole is provided on the mounting seat, the output shaft of the servo motor passes through the shaft hole to connect with the turntable, the protective cover is sleeved on the outside of the turntable, and The mounting seat is connected, the upper surface of the protective cover is provided with a plurality of radial notches 41, the claws are installed on the claw seat 9, and the claw seats are correspondingly installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com