Double-label transmission device for double-label machine

A transmission device and transmission component technology, applied in the directions of transportation and packaging, cloth feeding mechanism, sewing machine components, etc., can solve the problems of low clothing production efficiency, and achieve the effect of satisfying production and processing needs, improving production efficiency, and convenient and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

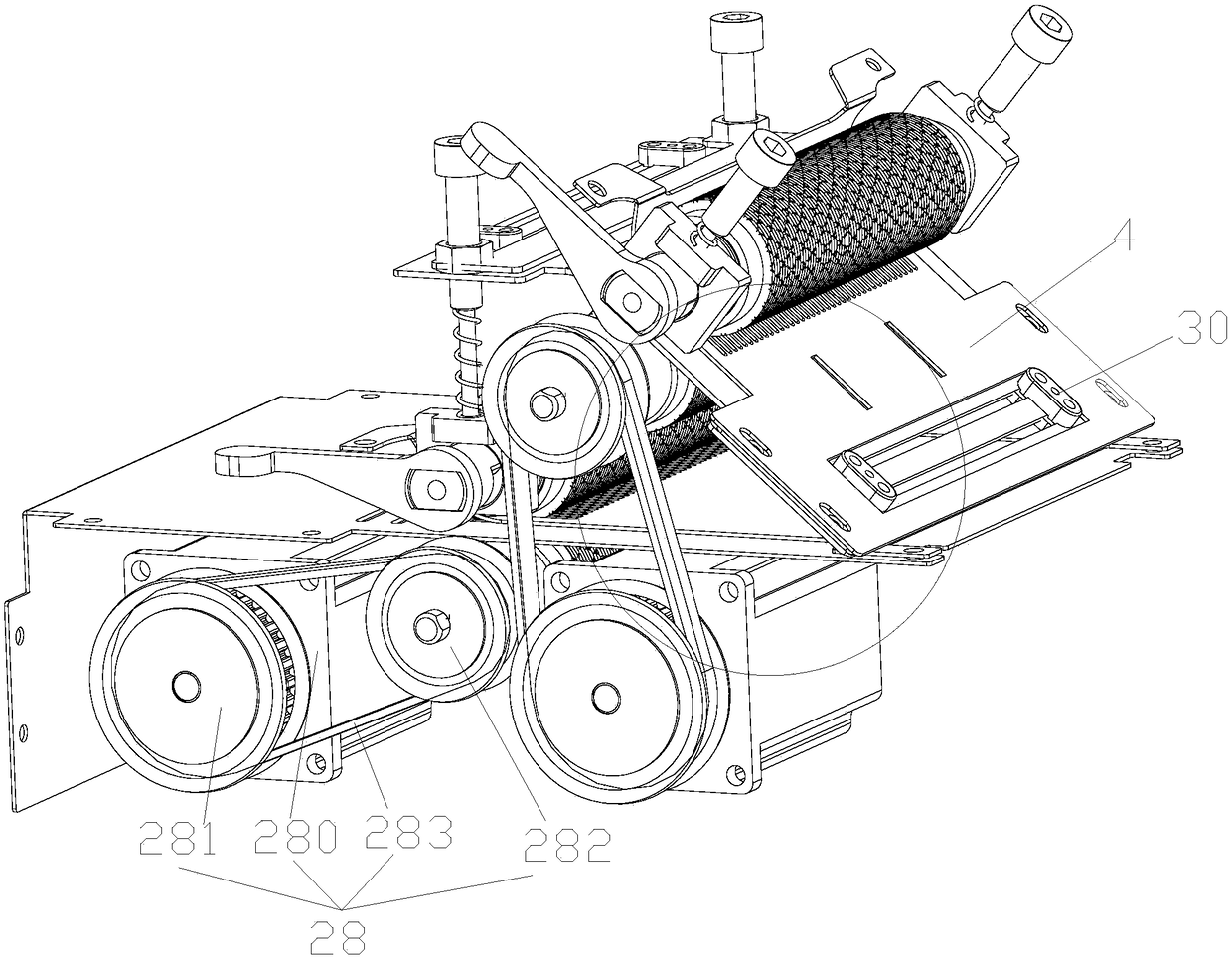

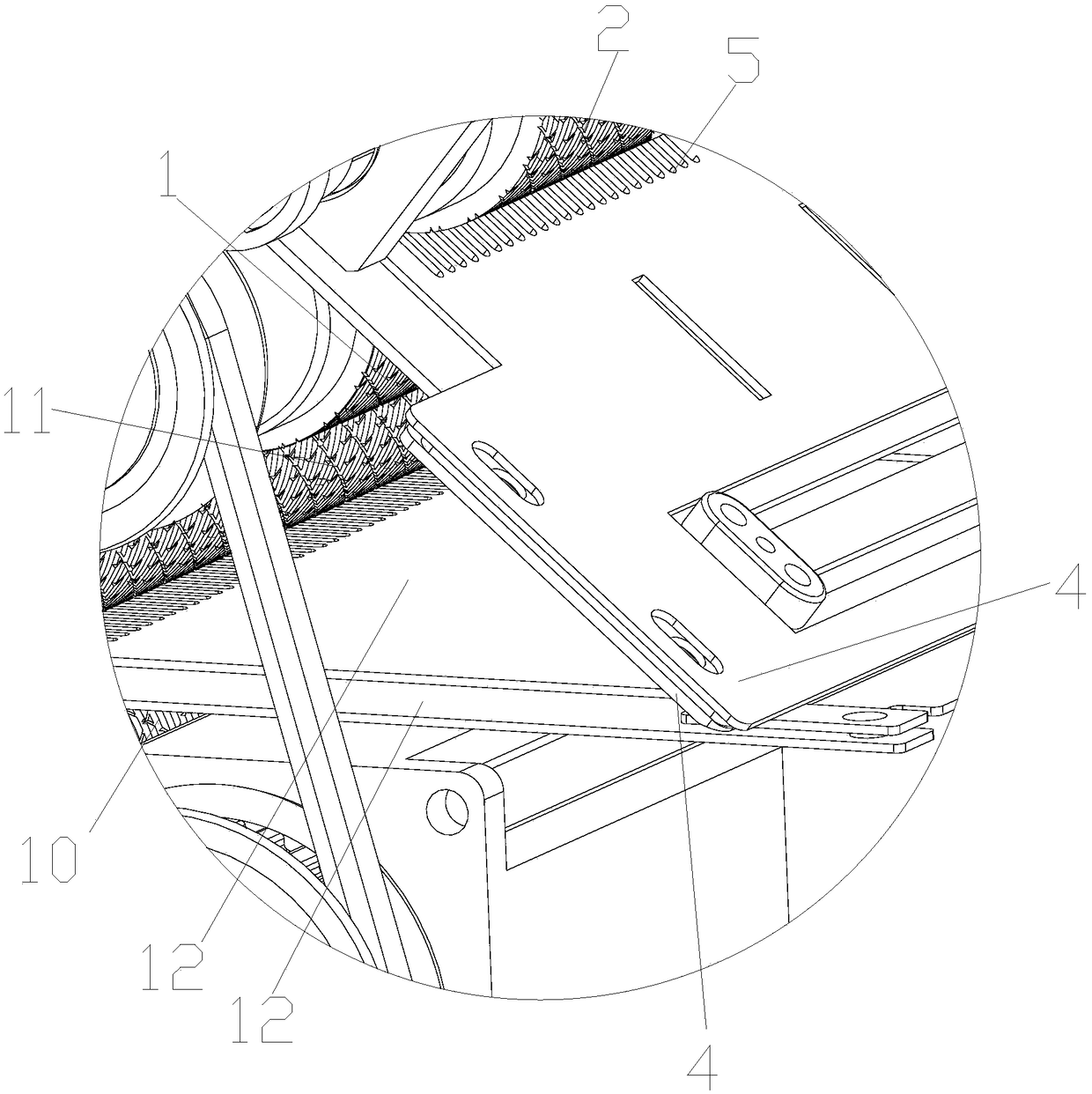

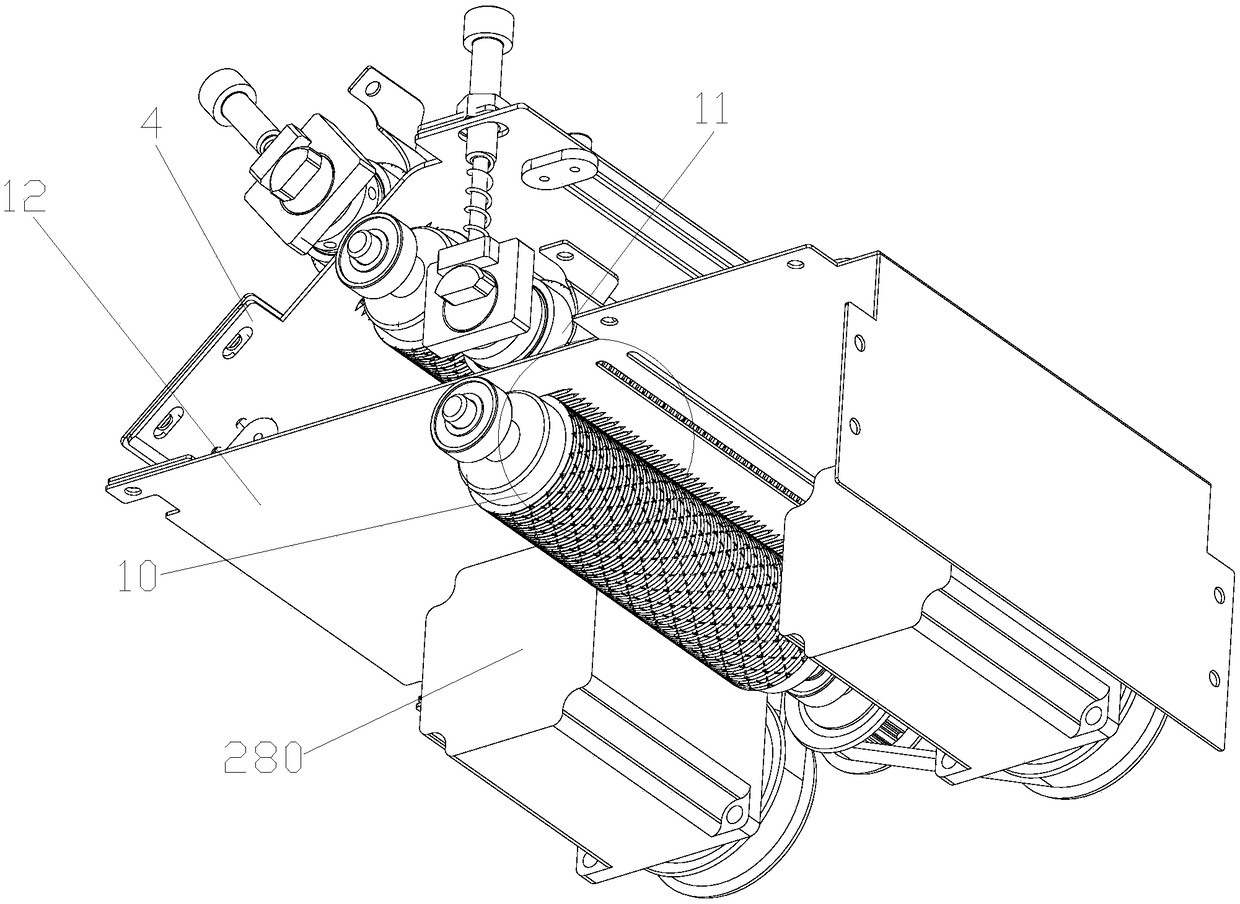

[0018] as attached Figure 1-4 The shown dual-label transmission device for a double-label machine of the present invention includes a superscript transmission component and a subscript transmission component arranged up and down, and one end of the above-mentioned superscript transmission component is closely attached to one end of the subscript transmission component. .

[0019] The superscript transmission assembly includes a first main roller 1, a first slave roller 2, a transmission ring 3, a power mechanism, a superscript clamping plate 4 and gaskets (not shown in the figure); the first main roller 1 Set opposite to the first slave roller 2, the length direction of the outer surface of the above two rollers is provided with a plurality of transmission rings 3 distributed sequentially; the first main roller 1 is rotated by the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap