Corner plastic coating cable core

A cable core and plastic-coating technology, applied in the direction of flexible shaft, linear motion axis, axis, etc., can solve the problems of vibration, noise, and easy rust of the cable core, so as to reduce the probability of vibration, prolong the service life, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

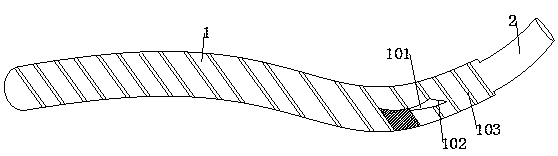

[0033] An angular plastic-coated cable core, such as figure 1 As shown, an angular plastic-coated cable core is provided with side strands 101 on the outer surface of the protective tube 1, the side strands 101 are fixedly connected to the protective tube 1, and a strand core 102 is penetrated and connected inside the side strands 101, By being provided with side strands 101 and strand cores 102, the compressive capacity of the protective tube 1 can be improved, and a side wire 103 is provided, and the structure of the side wires 103 and the side strands 101 being threaded is wound on the outer surface of the protective tube 1, and the side wire 103 can be improved. The stability between the strands 101 prevents loosening.

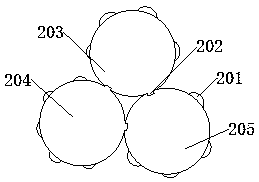

[0034] In the example, such as figure 2 As shown, a cable core 2 is arranged inside the protective tube 1, and the cable core 2 is composed of a cable core 1 203, a cable core 2 204 and a cable core 3 205, so that the cable core 1 203, the cable core 2 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com