A v-cone flowmeter with bionic microstructure on the surface

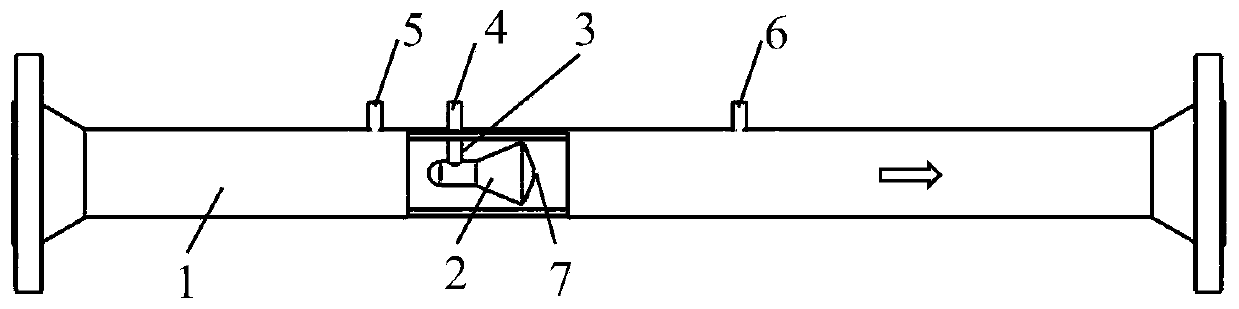

A microstructure and flowmeter technology, which is applied to the volume/mass flow generated by mechanical effects, and the direction of fluid flow detection by measuring differential pressure. The effect of coefficient, energy saving and flow resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

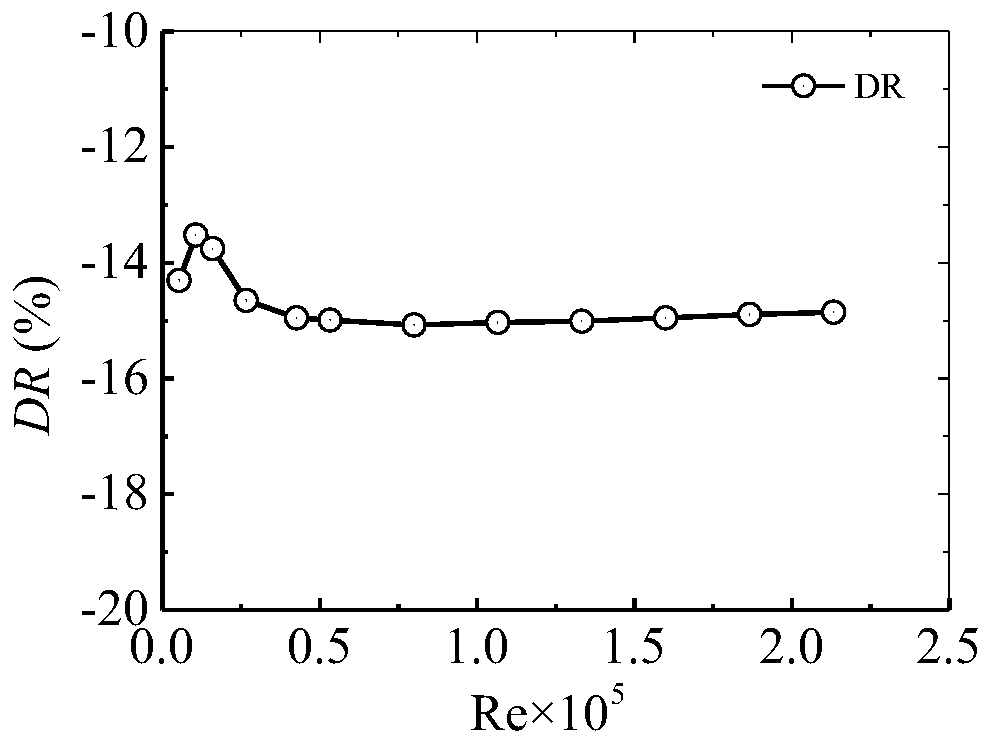

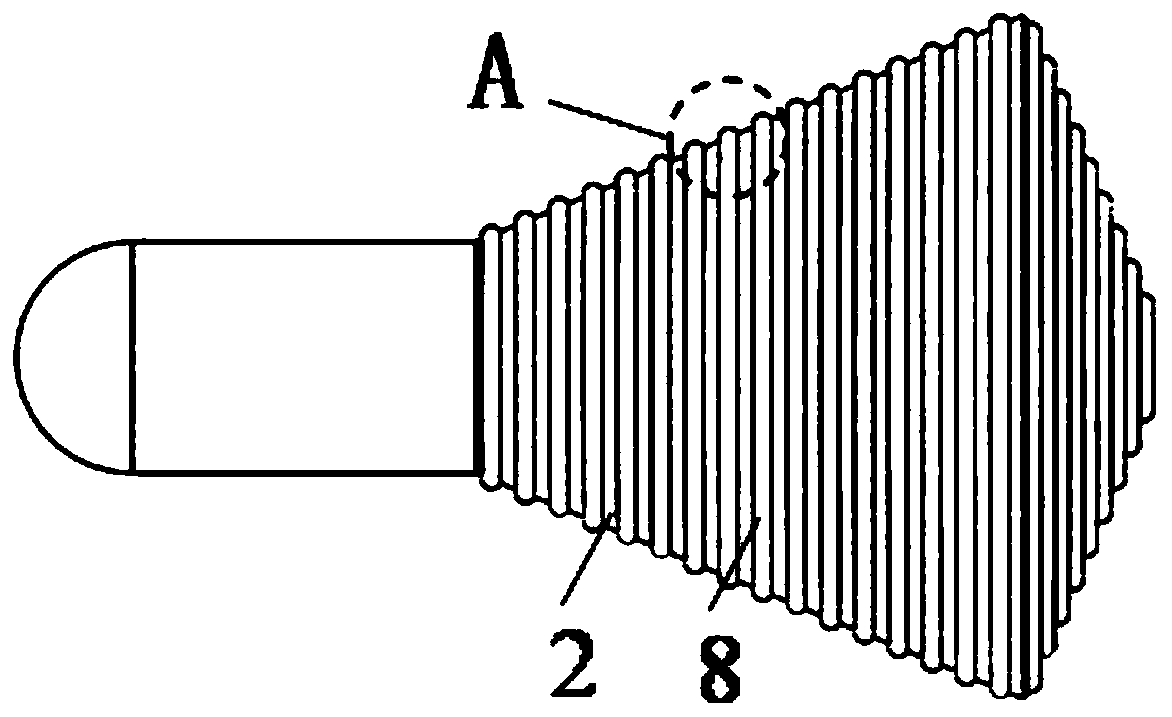

[0039] The rib microstructure is arranged on the surface of the V-shaped cone, and the schematic diagram is as follows image 3 shown. The ribs are arranged circumferentially along the surface of the cone, with a semicircular or arc-shaped cross section. The width of the ribs is W, the height is H, and the distance between adjacent ribs is L. The ratio of the width W of the rib cross-section to the height H, W:H=2:1~4:1, the distance L between adjacent ribs is, L=(0~2)W, preferably, when W:H=2: 1. When L=W, the V-cone flowmeter has the best drag reduction effect. Define the rent reduction rate DR as

[0040]

[0041] In the formula, Δω′ is the pressure loss after microstructures are arranged on the surface of the V-cone flowmeter cone, and Δω is the pressure loss without microstructures on the surface of the V-cone flowmeter cone.

[0042] When DR is a negative value, it indicates that the flow resistance of the V-cone flowmeter decreases, otherwise, the flow resistance ...

Embodiment approach 2

[0044] Groove microstructures are arranged on the surface of the V-shaped cone, and the schematic diagram is as follows Figure 5 and Figure 6 shown. The grooves are arranged circumferentially along the surface of the cone. The cross-sectional shape of the grooves is arc-shaped or semicircular. The ratio of the width W of the groove cross-section to the height H is W:H=2:1~4:1, adjacent The rib spacing L is, L=(0-2)W, preferably, when W:H=2:1, L=W, the V-cone flowmeter has the best drag reduction effect.

Embodiment approach 3

[0046] The convex hull microstructure is arranged on the surface of the V-shaped cone, and the schematic diagram is as follows Figure 7 and Figure 8 shown. The cross-sectional shape of the convex hull is arc-shaped or semicircular, and the ratio of the width W to the height H of the groove cross-section is W:H=2:1-4:1. The number of convex hulls is multiple, and they are aligned vertically and horizontally on the surface of the V-shaped cone, arranged in a criss-cross pattern on the surface of the V-shaped cone, or arranged irregularly on the surface of the V-shaped cone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com