Height adjustment power maintenances rack with high-efficiency oil dissolver

A technology for power maintenance racks and adjustment devices, which is applied to switchgear, electrical components, overhead line/cable equipment, etc., can solve problems such as energy consumption for hot water heating, inability to instantaneously improve oil-dissolving efficiency, and difficulty in old oil. achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

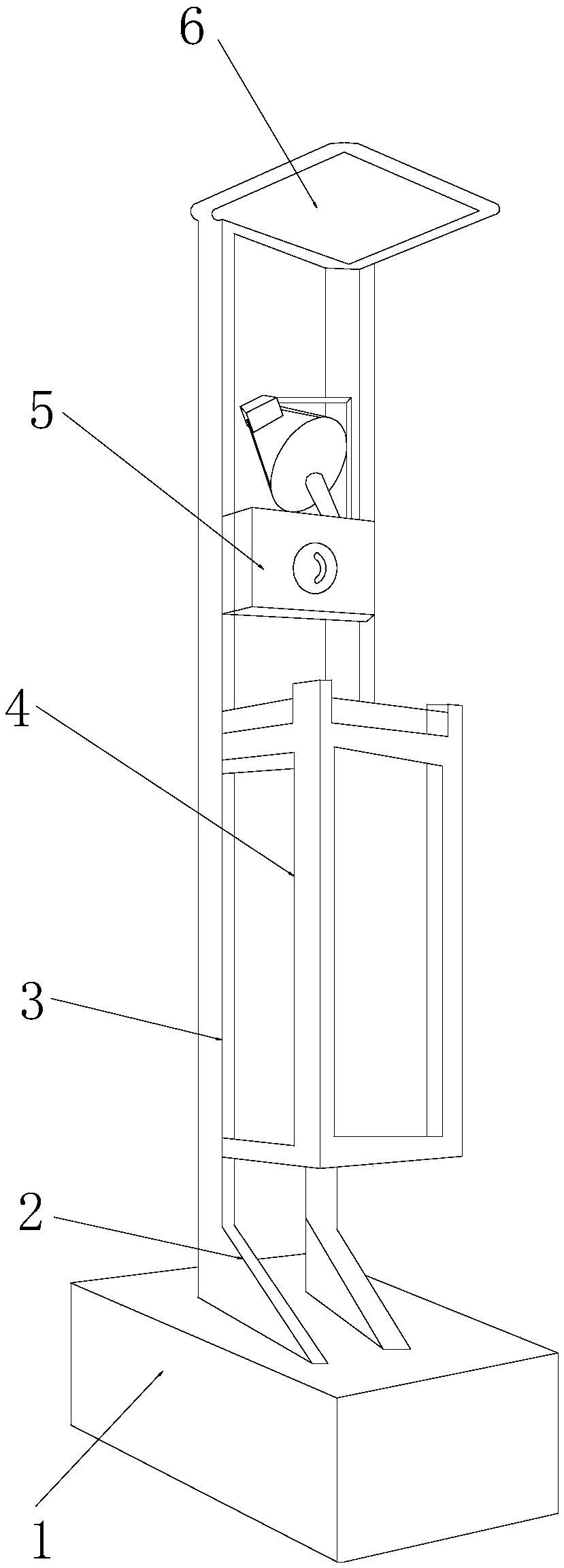

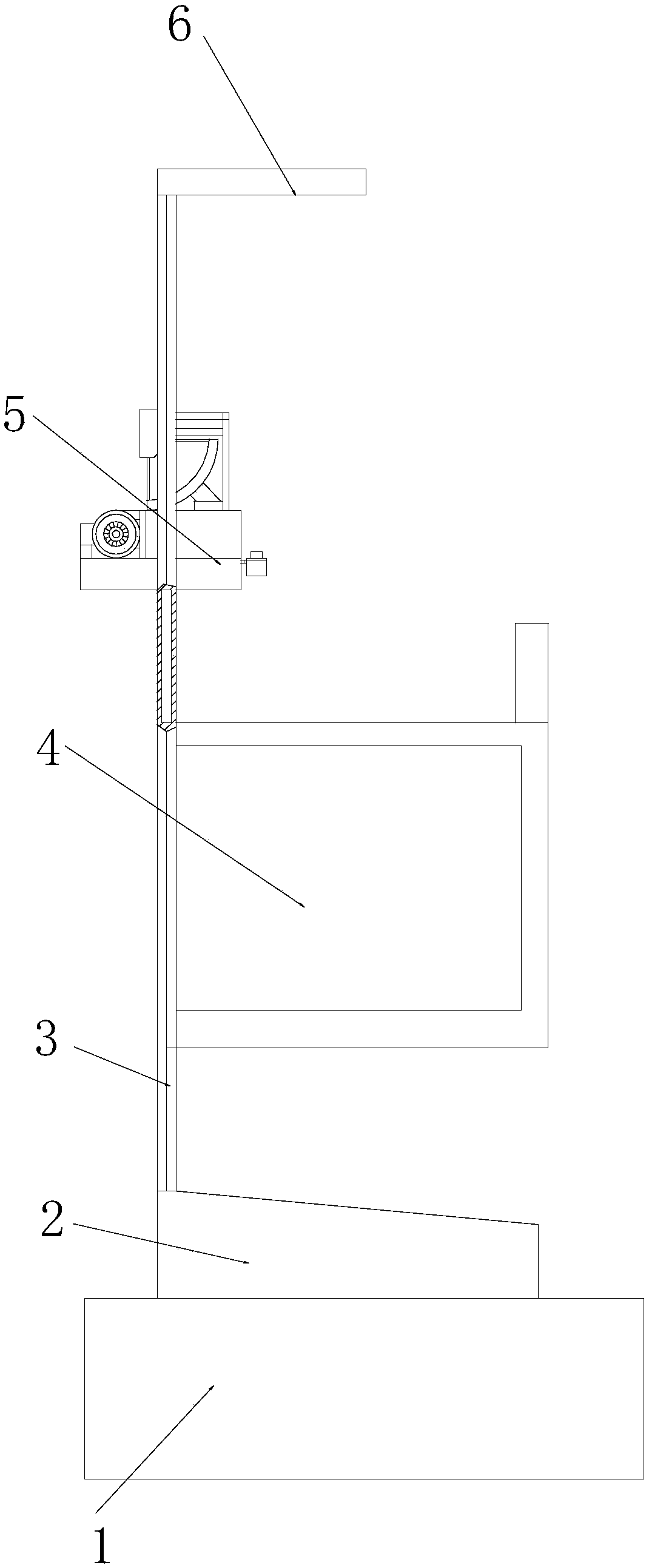

[0029] see figure 1 and figure 2 , the present invention provides an electric maintenance stand with adjustable height and equipped with a high-efficiency oil-dissolving device. The chute frame 3 is located on the upper surface of the fixed frame 2 and forms an integrated structure with the fixed frame 2 by welding, the workbench 4 is embedded in the chute frame 3 and both adopt clearance fit, and the device shell The body 1 and the fixed frame 2 are perpendicular to each other and are installed on the lower surface of the fixed frame 2 by welding. The photovoltaic panel 6 is perpendicular to the upper surface of the chute frame 3 and the two are connected to form an integrated structure. The high-efficiency oil-dissolving The device 5 is parallel to the workbench 4 up and down while being embedded in the inside of the chute frame 3 for mechanical connection, and the device base 2 is a metal structure with a triangular structure.

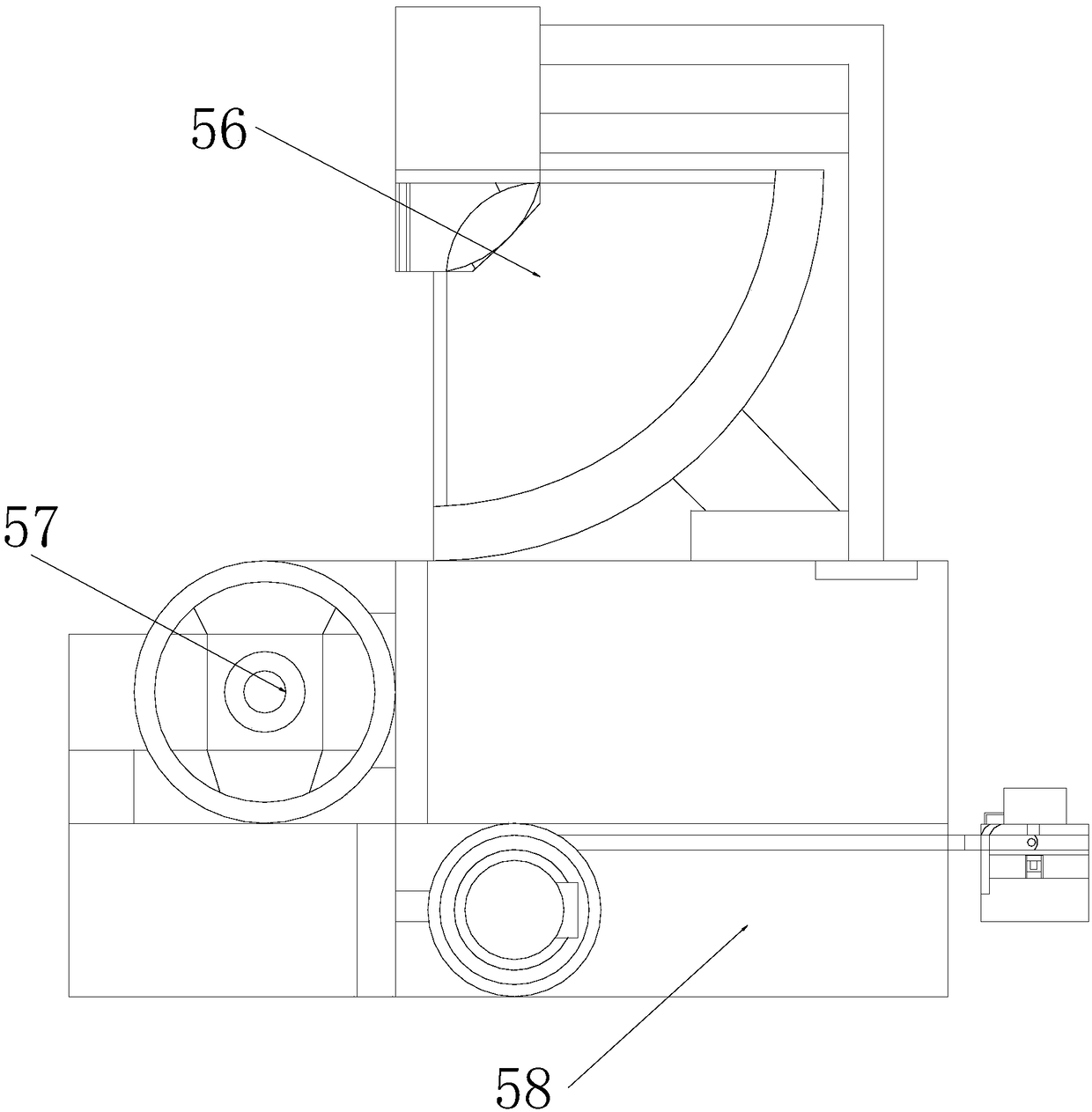

[0030] see image 3 , the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com