Assembled exhibition stand for textiles

A technology for exhibition racks and textiles, applied in display hangers, display shelves, display stands, etc., can solve the problems of textile waste and difficult textiles, and achieve the effect of preventing waste and facilitating exhibitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

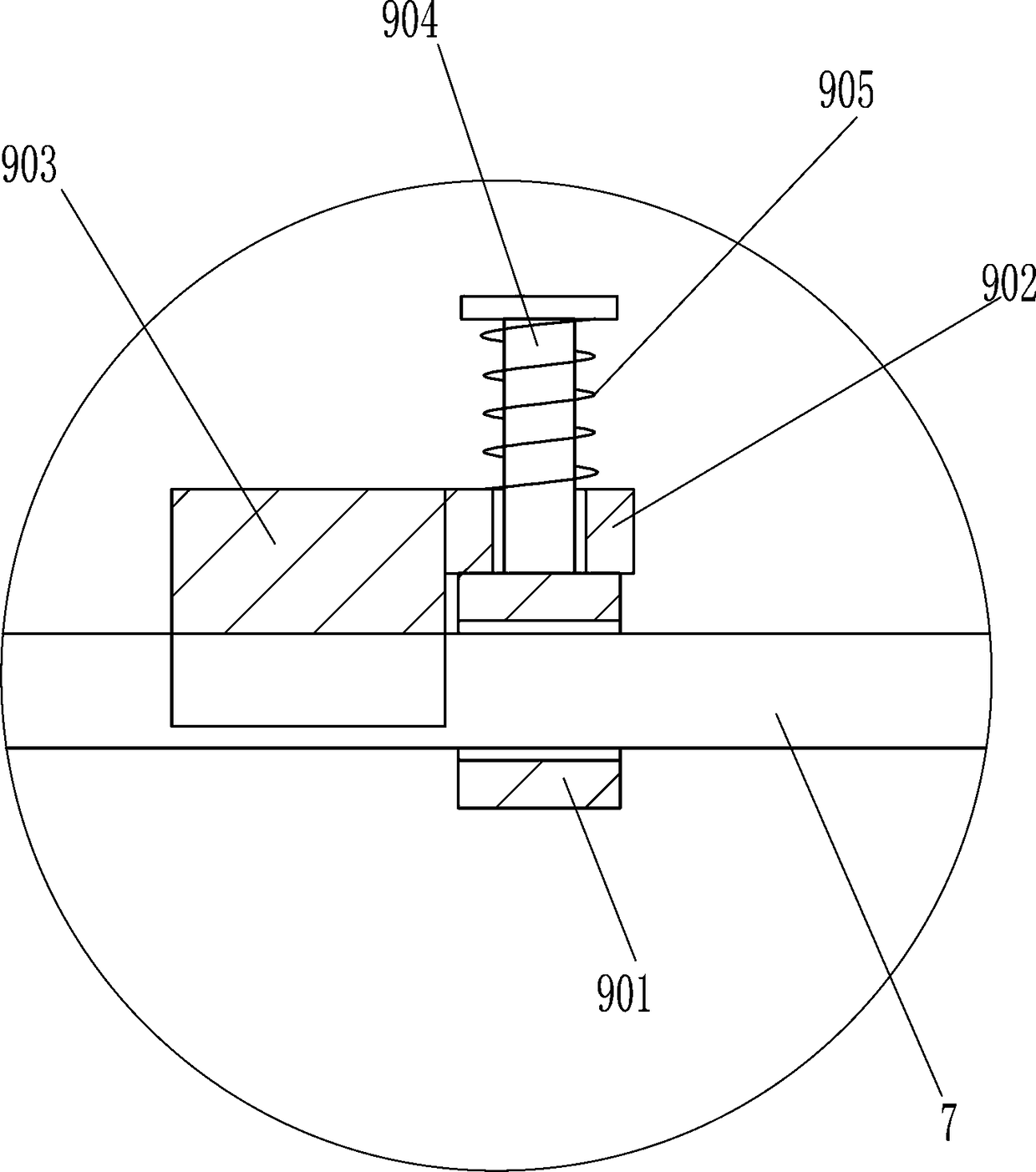

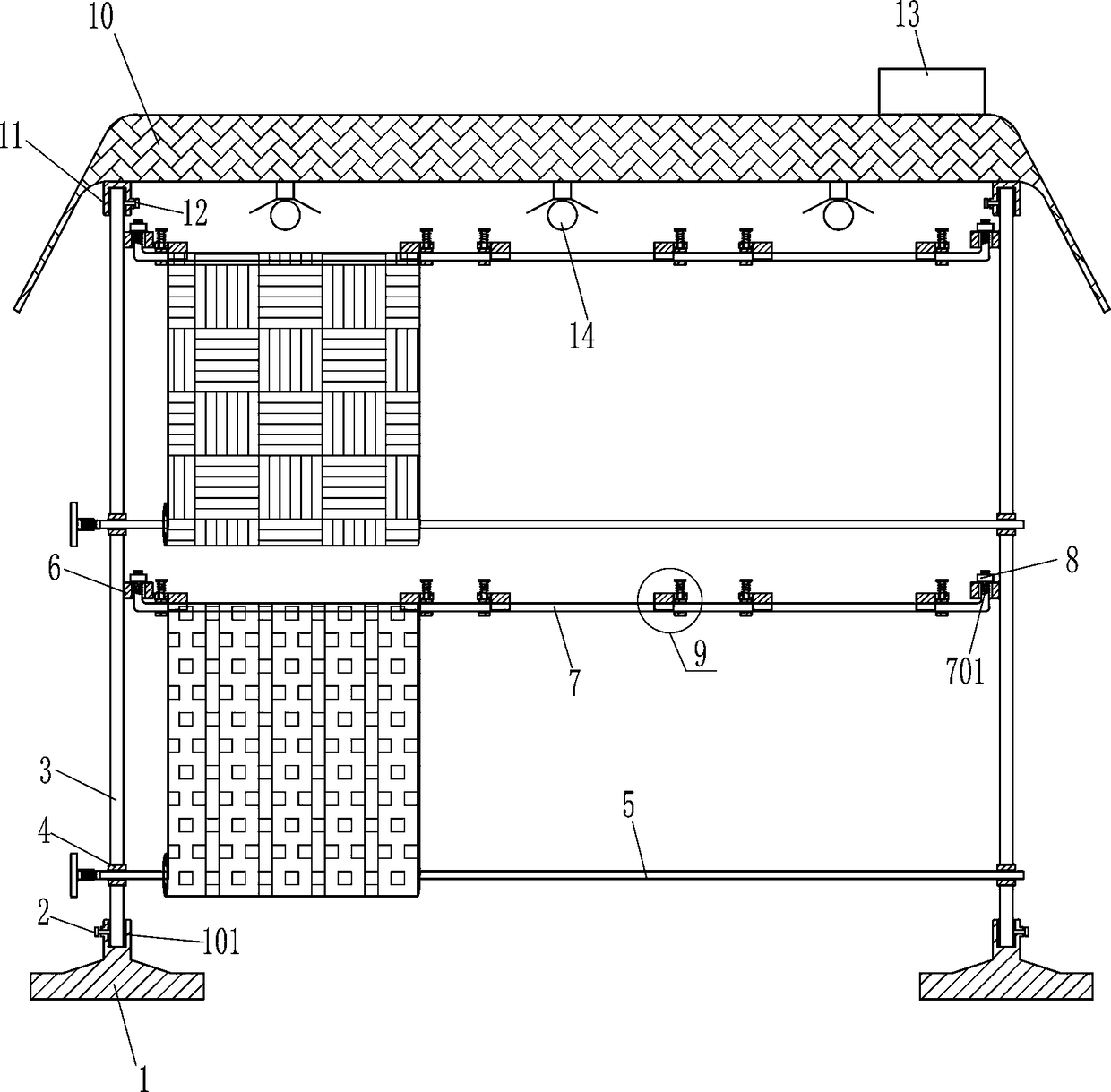

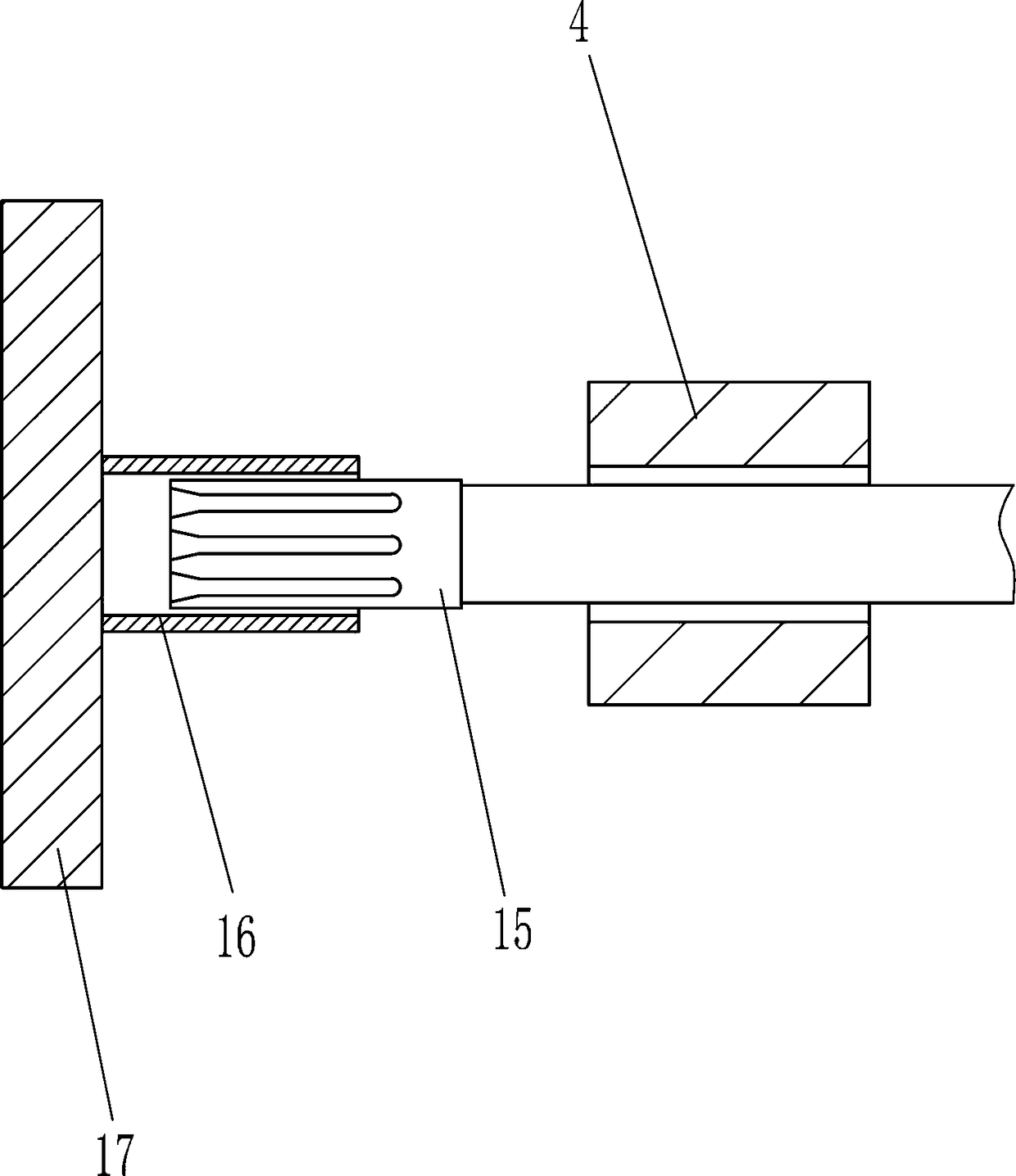

[0019] A textile assembly display stand, such as Figure 1-3 As shown, it includes a base 1, a first screw 2, a support plate 3, a sleeve 4, a rotating rod 5, an orifice 6, a U-shaped rod 7, a nut 8 and a clamping device 9 for fixing. The top of the base 1 There is a card slot 101 for fixing, and a support plate 3 for supporting is slidably provided in the card slot 101, first screws 2 are provided on the outer surface of the base 1 on the left and right sides, and four screws 2 are provided on the casing 4. , respectively embedded in the middle and lower parts of the support plates 3 on the left and right sides, a rotating rod 5 is slidingly provided between the two left and right casings 4, and there are four orifice plates 6, which are respectively installed on the left and right sides of the support plates 3 The upper part and the middle part of the inner surface, the left and right two orifice plates 6 are provided with U-shaped bars 7, the left and right sides of the U-s...

Embodiment 2

[0021] A textile assembly display stand, such as Figure 1-3 As shown, it includes a base 1, a first screw 2, a support plate 3, a sleeve 4, a rotating rod 5, an orifice 6, a U-shaped rod 7, a nut 8 and a clamping device 9 for fixing. The top of the base 1 There is a card slot 101 for fixing, and a support plate 3 for supporting is slidably provided in the card slot 101, first screws 2 are provided on the outer surface of the base 1 on the left and right sides, and four screws 2 are provided on the casing 4. , respectively embedded in the middle and lower parts of the support plates 3 on the left and right sides, a rotating rod 5 is slidingly provided between the two left and right casings 4, and there are four orifice plates 6, which are respectively installed on the left and right sides of the support plates 3 The upper part and the middle part of the inner surface, the left and right two orifice plates 6 are provided with U-shaped bars 7, the left and right sides of the U-s...

Embodiment 3

[0024] A textile assembly display stand, such as Figure 1-3 As shown, it includes a base 1, a first screw 2, a support plate 3, a sleeve 4, a rotating rod 5, an orifice 6, a U-shaped rod 7, a nut 8 and a clamping device 9 for fixing. The top of the base 1 There is a card slot 101 for fixing, and a support plate 3 for supporting is slidably provided in the card slot 101, first screws 2 are provided on the outer surface of the base 1 on the left and right sides, and four screws 2 are provided on the casing 4. , respectively embedded in the middle and lower parts of the support plates 3 on the left and right sides, a rotating rod 5 is slidingly provided between the two left and right casings 4, and there are four orifice plates 6, which are respectively installed on the left and right sides of the support plates 3 The upper part and the middle part of the inner surface, the left and right two orifice plates 6 are provided with U-shaped bars 7, the left and right sides of the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com