Quartz sand surface dirt washing tank

A technology for surface dirt and quartz sand, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Completely remove and other problems to achieve the effect of full and complete flushing effect, increased contact and collision, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

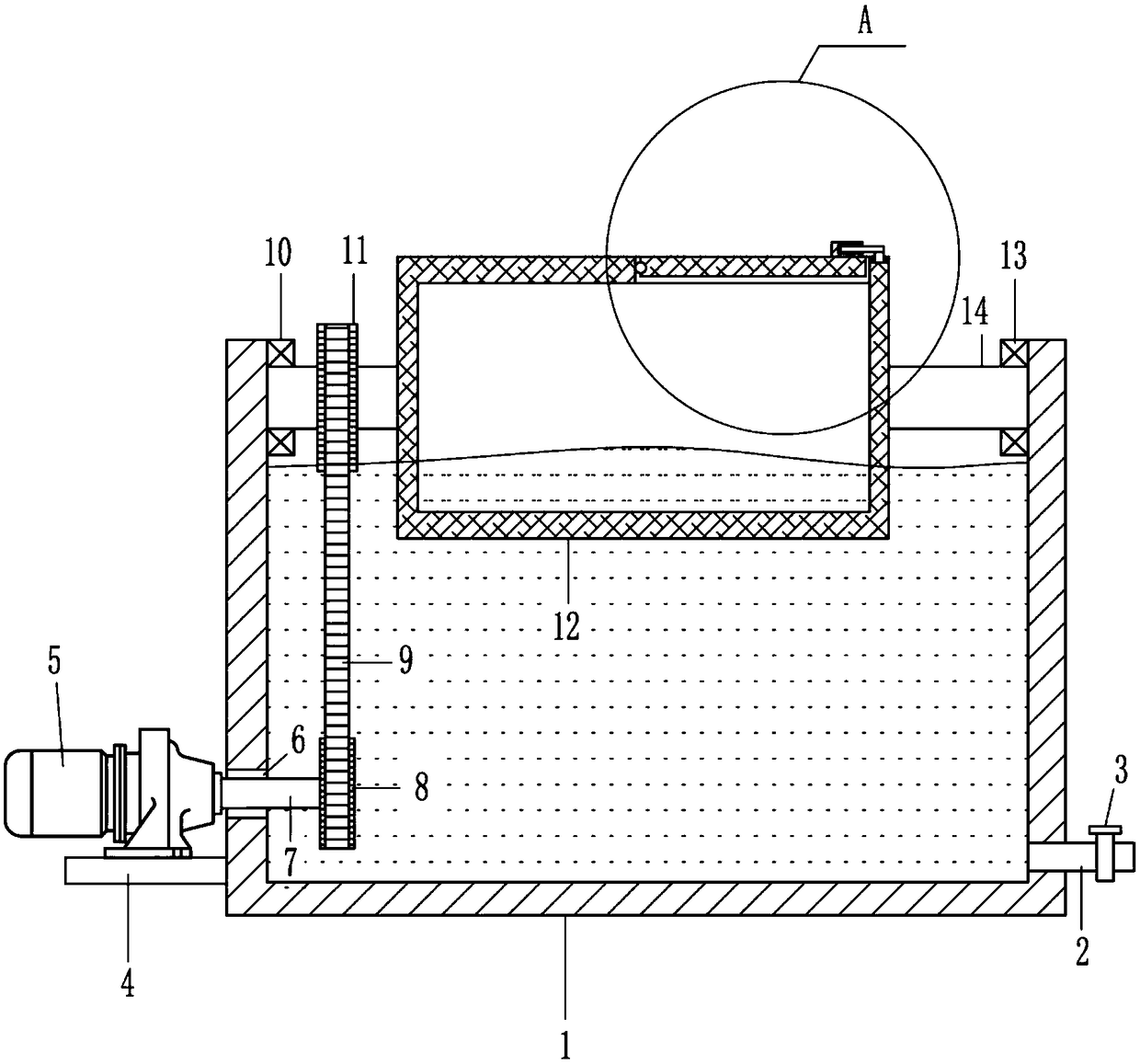

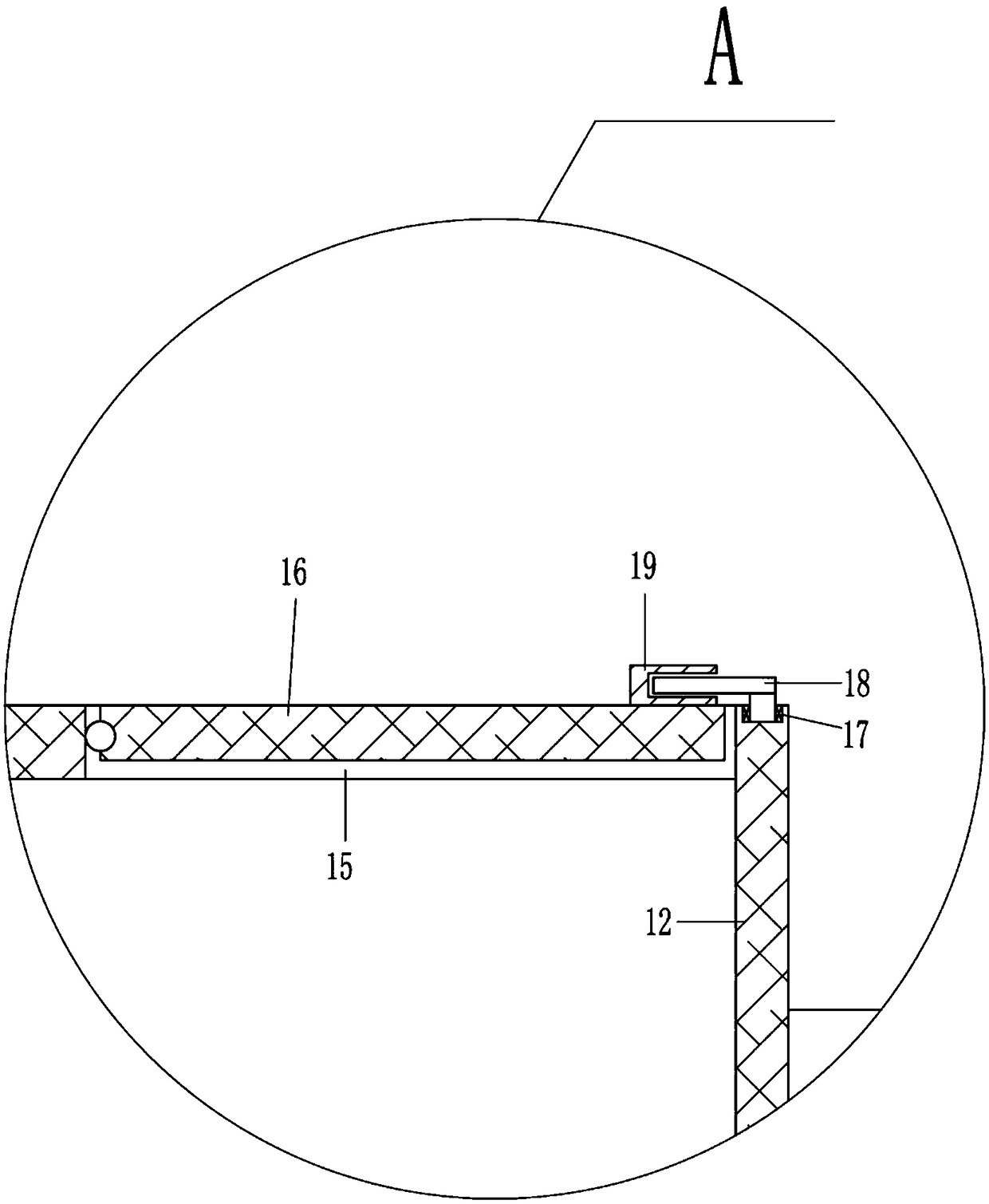

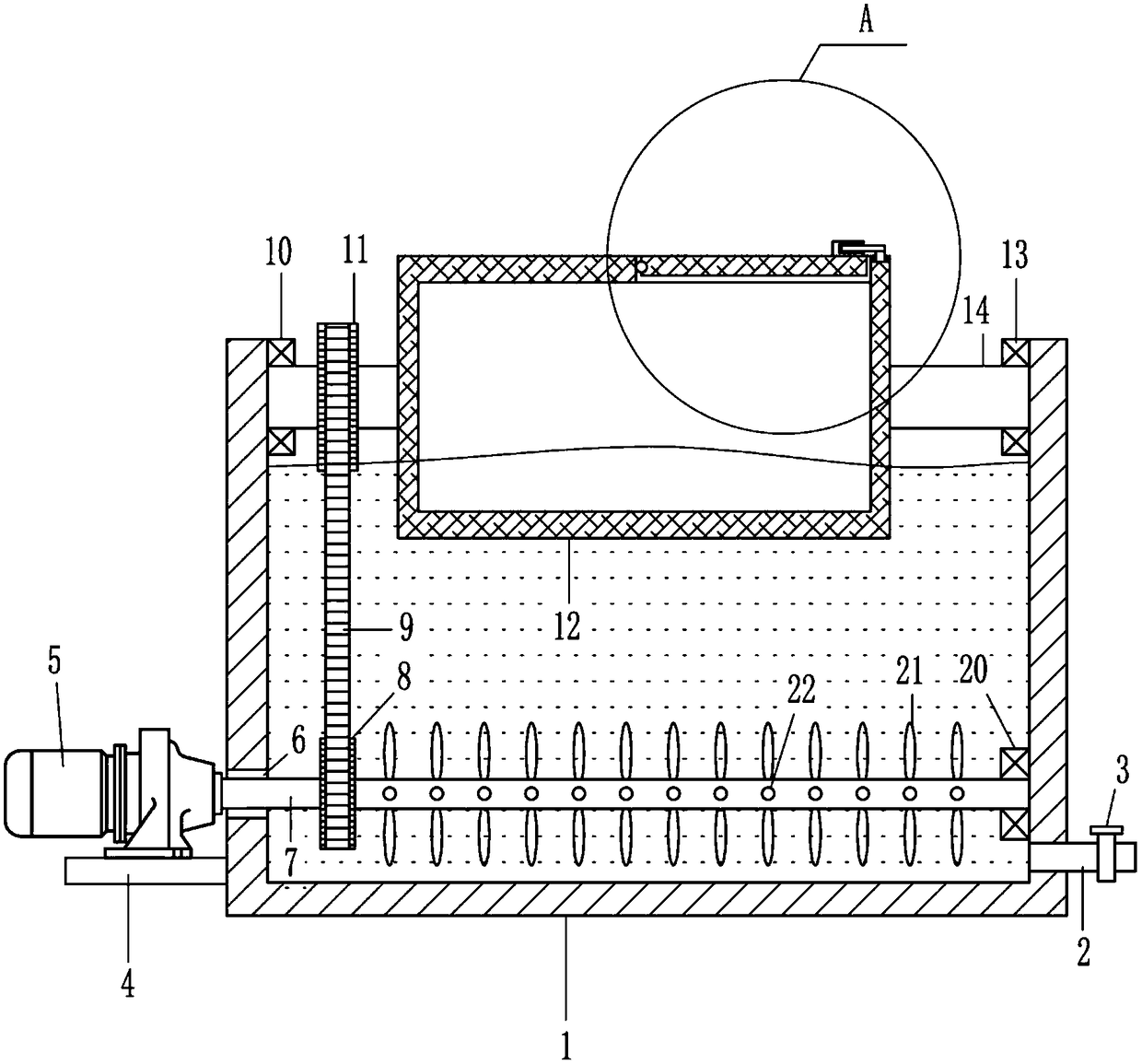

[0021] A quartz sand surface dirt washing box, such as Figure 1-7 As shown, it includes a cleaning box 1, an outlet pipe 2, a valve 3, a mounting plate 4, a motor 5, a sealing ring 6, a first rotating shaft 7, a first gear 8, a transmission chain 9, a first bearing seat 10, and a second gear 11. Washing net box 12, second bearing seat 13, second rotating shaft 14, mesh cover plate 16, third bearing seat 17, insertion rod 18 and latch 19; installation plate 4 is fixed on the outer wall of cleaning box 1, motor 5 Fixed on the top surface of the mounting plate 4; the first rotating shaft 7 is connected to the output end of the motor 5, and extends through the sealing ring 6 to the cleaning box 1; the first gear 8 is fixed on the first rotating shaft 7, and is located in the cleaning box 1 inside; the outlet pipe 2 is fixedly connected to the cleaning tank 1, and communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com