Steel truss welding methods for various angles

A welding method and steel truss technology, applied in the field of steel truss welding, can solve problems such as poor welding angle, low efficiency, and affecting quality of use, and achieve the effects of easy operation, good quality, and improved welding efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

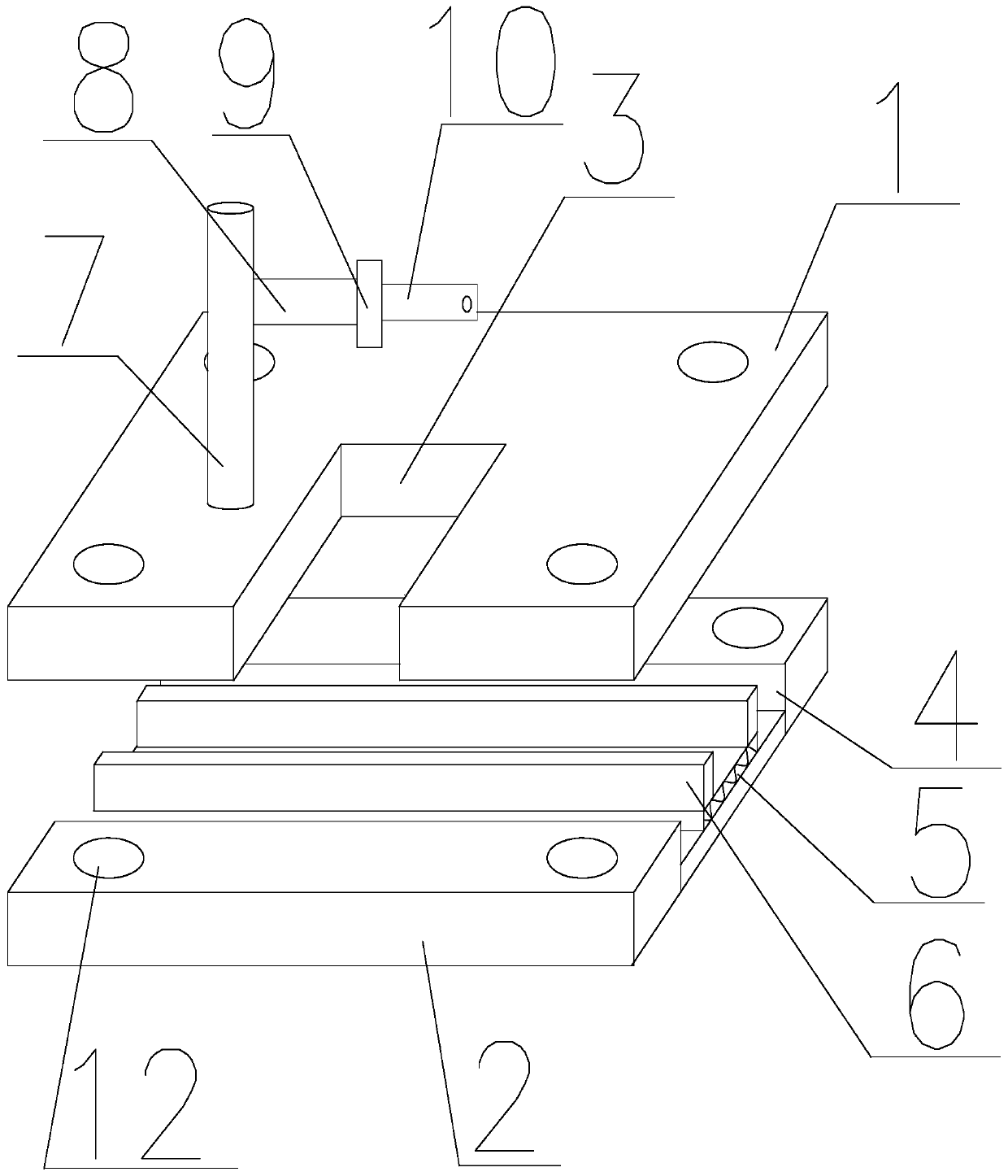

[0038] like figure 1 and figure 2 Shown, the present invention comprises the following steps:

[0039] (1) The steel pipe to be welded is fixedly placed on the second fixed plate 2;

[0040] (2) The first fixed plate 1 is located directly above the second fixed plate 2, and the first fixed plate 1 is provided with a first fixed plate 1 with one end passing through the side of the first fixed plate 1 and the other end inside the first fixed plate 1, on the horizontal plane. A groove 3, the side of the first groove 3 on the first fixed plate 1 is provided with a first telescopic rod 7 that can expand and contract in the vertical direction, and the upper end of the first telescopic rod 7 is connected with the first telescopic rod that can expand and contract in the horizontal direction. One end of the two telescopic rods 8 is connected, and the other end of the second telescopic rod 8 is vertically connected with the first support rod 9, and the first support rod 9 is connecte...

Embodiment 2

[0045] The steel truss welding method is suitable for various angles. The new welding device for welding steel trusses of the present invention includes steel pipes for welding trusses and a fixing device for fixing steel pipes. The fixing device includes a first fixing plate 1 and a second fixing plate. Two fixed plates 2, the first fixed plate 1 is located directly above the second fixed plate 2, and the first fixed plate 1 is provided with one end that runs through the side of the first fixed plate 1 and the other end is inside the first fixed plate 1, on a horizontal plane The first groove 3 on the top, the second fixed plate 2 is provided with a second groove 4 on the horizontal plane with two ends penetrating through the opposite two sides of the second fixed plate 2, and the inner bottom surface of the second groove 4 The spring plate 5 that can expand and contract along the width direction of the second groove 4 is set, and the two ends of the telescopic end of the spri...

Embodiment 3

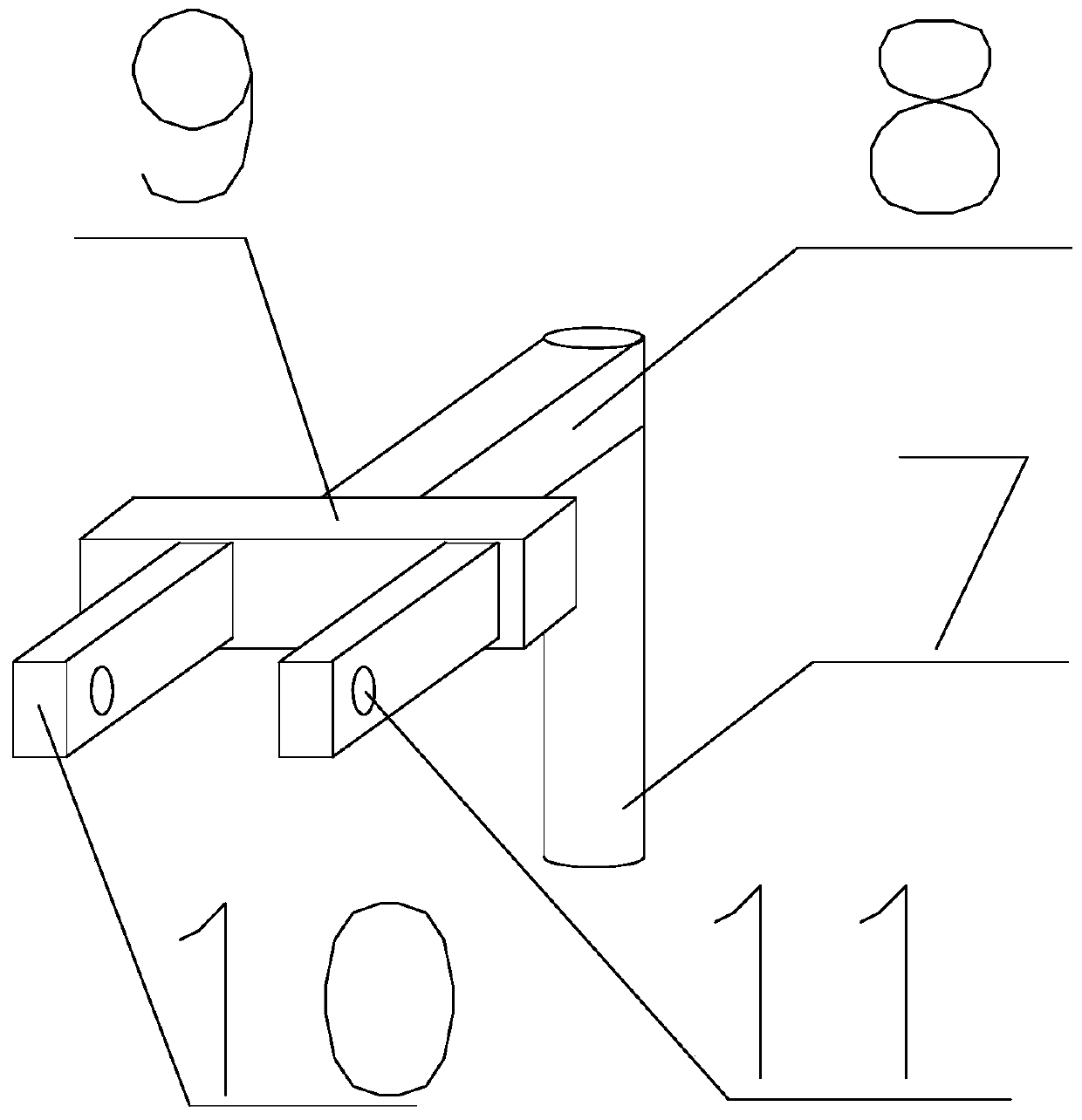

[0047] It is applicable to steel truss welding methods at various angles. On the basis of Embodiment 2, the clamping device includes two connecting plates 10 vertically arranged on the first support rod 9 at one end. The connecting plates 10 are located on the horizontal plane and located on the second Above a groove 3, a chute on the horizontal plane is provided on the surface connecting the first support rod 9 and the connecting plate 10, one end of the connecting plate 10 slides along the direction where the chute is located, and the other end of the connecting plate 10 is provided through There is a fixing groove 11, which is fixedly connected through bolts, and the steel pipe is fixed between two connecting plates 10, and the connecting plate 10 slides along the chute, and is fixedly connected to the steel pipe in between through the fixing groove 11 through the bolts. Several convex lines are arranged on two opposite surfaces of the connecting plate 10, and the convex lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com