Foldable bulk material lifting device

A folding and bulk material technology, applied in the direction of loading/unloading, transportation and packaging, conveyor objects, etc., can solve the problems of increasing transportation difficulty and transportation cost, height limitation, etc., and achieve the goal of reducing transportation difficulty and transportation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

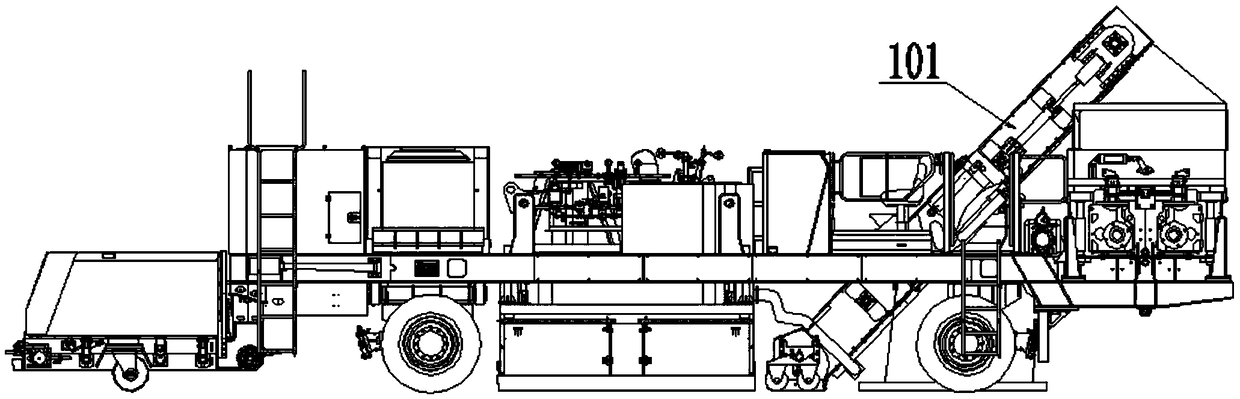

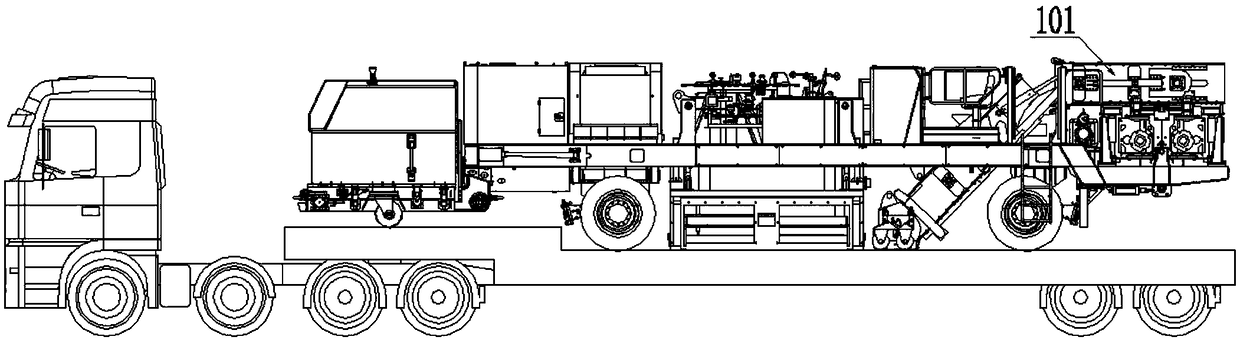

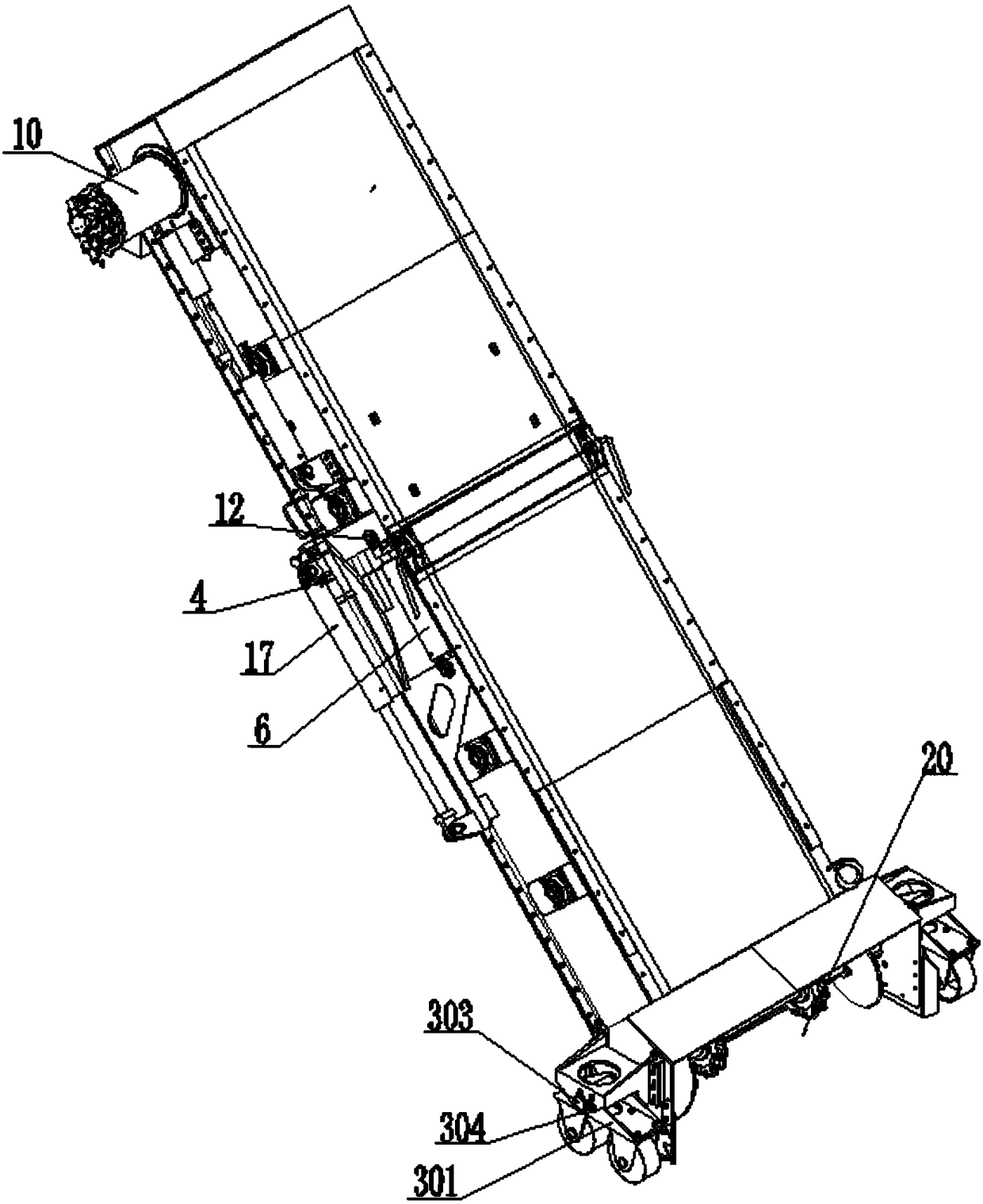

[0033] In conjunction with the accompanying drawings, a foldable bulk material lifting device 101 includes a material lifting main body section 1 and a material lifting folding section 2. The bottom of the material lifting main body section 1 is provided with a walking leg 3, and the top of the material lifting main body section is in contact with the lifting body. The bottom hinge of the material folded section. A slideway 4 is provided at the hinge of the material lifting main body section and the material lifting and folding section, and a rotating shaft 5 is arranged on the slideway 4. The corner of the bottom of the material lifting and folding section can be lifted in a horizontal position along the rotating axis on the slideway. Rotate between inclination angles of the main body segment. A folding oil cylinder 6 is also arranged between the material lifting main body section and the material lifting folding section, the cylinder body end of the folding oil cylinder is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com