High-linearity longitudinal automatic edge wrapping machine for carpet

A linear, hemming machine technology, applied in the direction of cloth feeding mechanism, sewing machine components, textile and paper making, etc., can solve the problems of low production efficiency and quality, high labor intensity of workers, large carpet area, etc. The effect of saving manpower and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

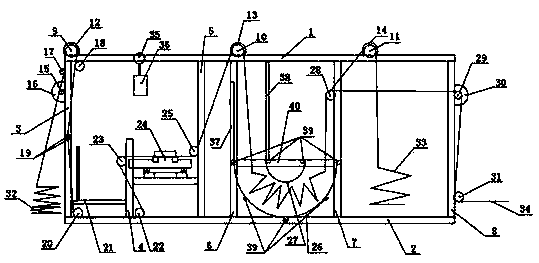

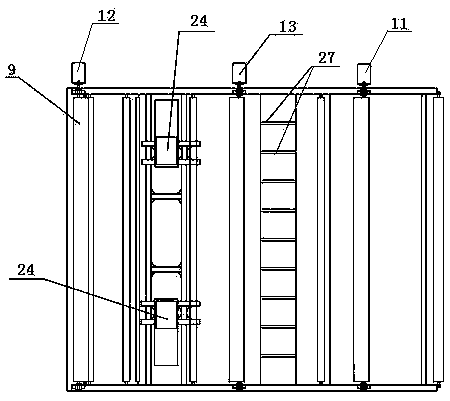

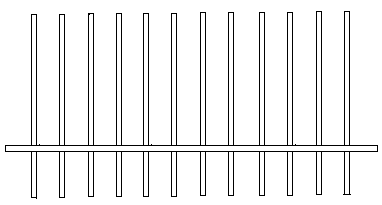

[0027] In the figure: 1. Upper beam, 2. Lower base frame, 3. Longitudinal bar I, 4. Longitudinal bar II, 5. Longitudinal bar III, 6. Longitudinal bar IV, 7. Longitudinal bar V, 8. Longitudinal bar VI, 9. Drive wheel Ⅰ, 10, drive wheel Ⅱ, 11, drive wheel Ⅲ, 12, reducer Ⅰ, 13, reducer Ⅱ, 14, reducer Ⅲ, 15, guide rod Ⅰ, 16, baffle plate Ⅰ, 17, Guide rod Ⅱ, 18, driven wheel Ⅰ, 19, limit rod, 20, driven wheel Ⅱ, 21, platform, 22, driven wheel Ⅲ, 23, driven wheel Ⅳ, 24, hemming table, 25, driven wheel Ⅴ , 26, curved plate, 27, curved fence plate, 28, driven wheel Ⅵ, 29, driven wheel Ⅶ, 30, baffle plate Ⅱ, 31, driven wheel Ⅷ, 32, carpet feeding end, 33, carpet output end Ⅰ, 34, carpet output terminal Ⅱ, 35, pendant rod, 36, operation touch screen box, 37, grate I, 38, grate II, 39, horizontal fixed rod, 40, horizontal fixed rod.

[0028] Such as Figure 1-3 As shown, it inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com