Emergency Bridge Frame in Construction

A kind of technology in construction and bridge, applied in the direction of bridges, pedestrian bridges, bridge forms, etc., can solve problems such as vehicles cannot pass, and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

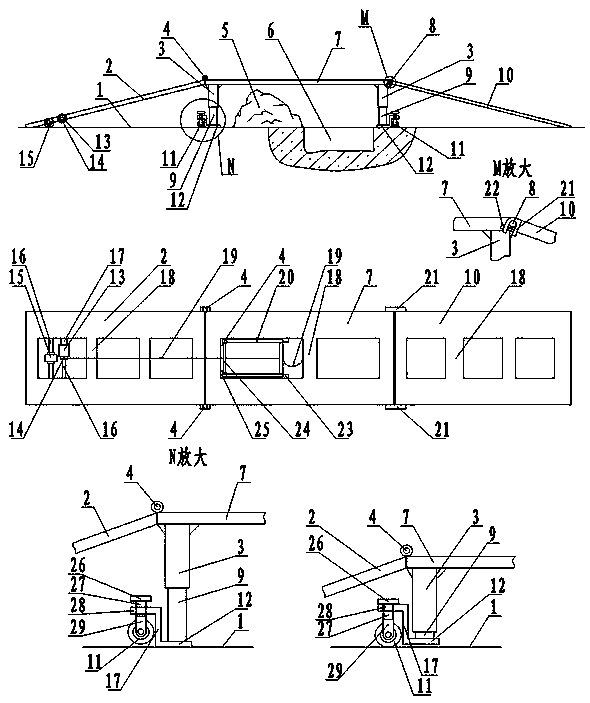

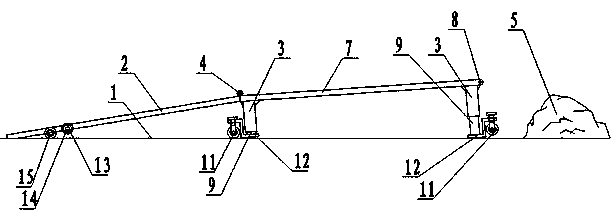

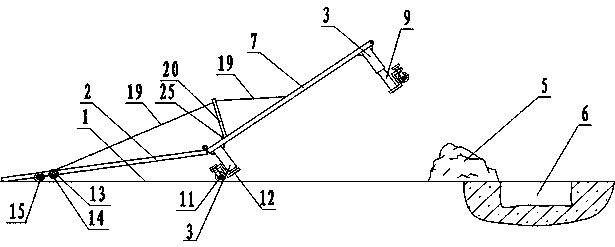

[0014] figure 1 In, is the bridge structure diagram. The picture above is the front view, and the third row is the top view. A transverse ditch6 was dug in the ground for construction. Concrete and earth crushed by impact are piled up into a slag ridge 5 on one side of the ditch 6 . Respectively connect a foot post cover 3 on four corners of main bridge frame 7 bottoms, the foot post cover 3 is a hollow square pipe. There are reinforcing ribs at both ends of the upper end of the foot column cover to connect with the main bridge frame. Foot column 9 is cuboid, and section is square. The foot column 9 is installed in the foot column cover 3 . The main bridge frame 7 front ends are connected and fixed with hanger pins 8 on the right side in the figure. As in the enlarged view of M, a hanging card 21 is installed on the upper end of the front auxiliary bridge frame 10, and the hanging card 21 is a fork shape. Hanging card 21 just forks on hanging card pin 8. A through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com