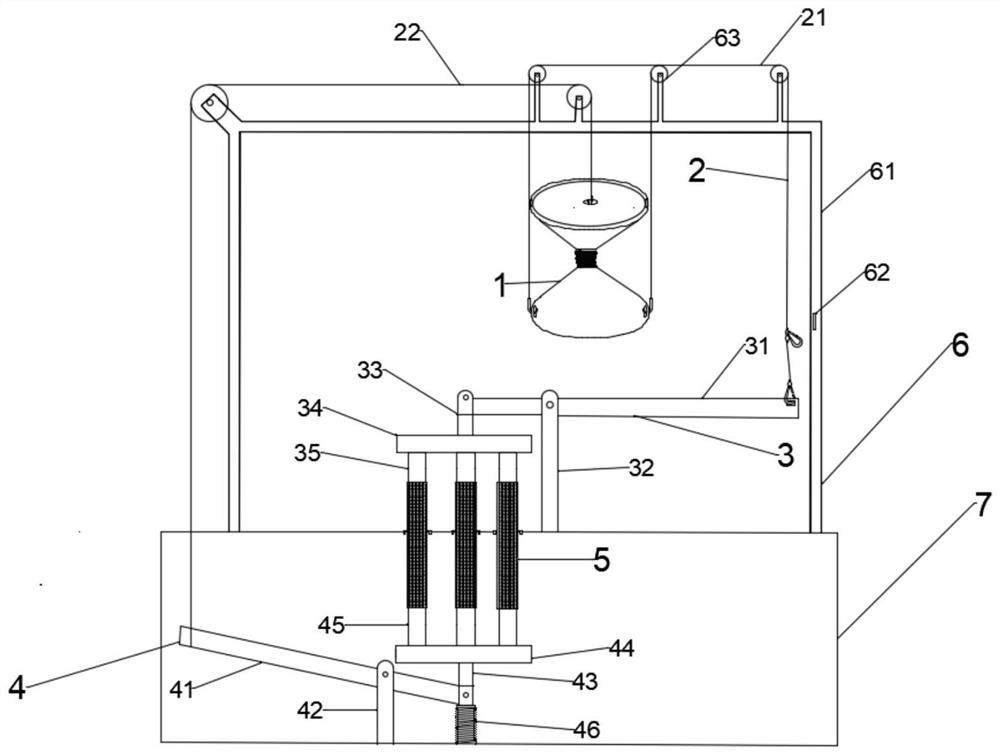

A parallel intelligent pressurized triaxial sample preparation process

A three-axis sample and parallel technology, which is applied in the preparation of test samples, infrastructure engineering, construction, etc., can solve the problems of sample cylinder sampling difficulties, reduce sample damage rate, facilitate sampling, and improve test performance. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] This embodiment is a parallel intelligent pressurized triaxial sample preparation process. The working process of this application is as follows:

[0066] (1) Preparation before experiment

[0067] According to the stress history, deposition conditions and particle composition of the soil used in the experiment, determine the pressure to be applied during the experiment and the time required for the experiment.

[0068] (2) Instrument preparation

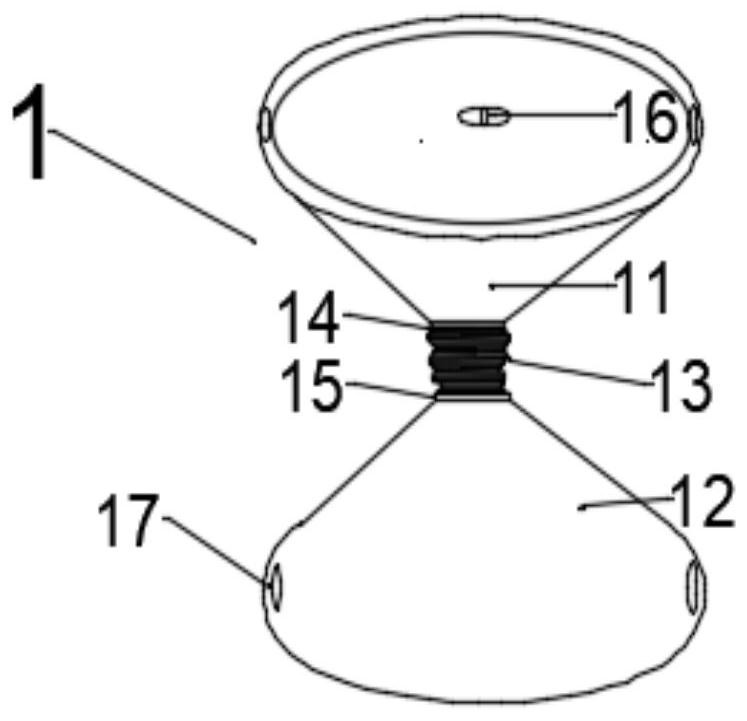

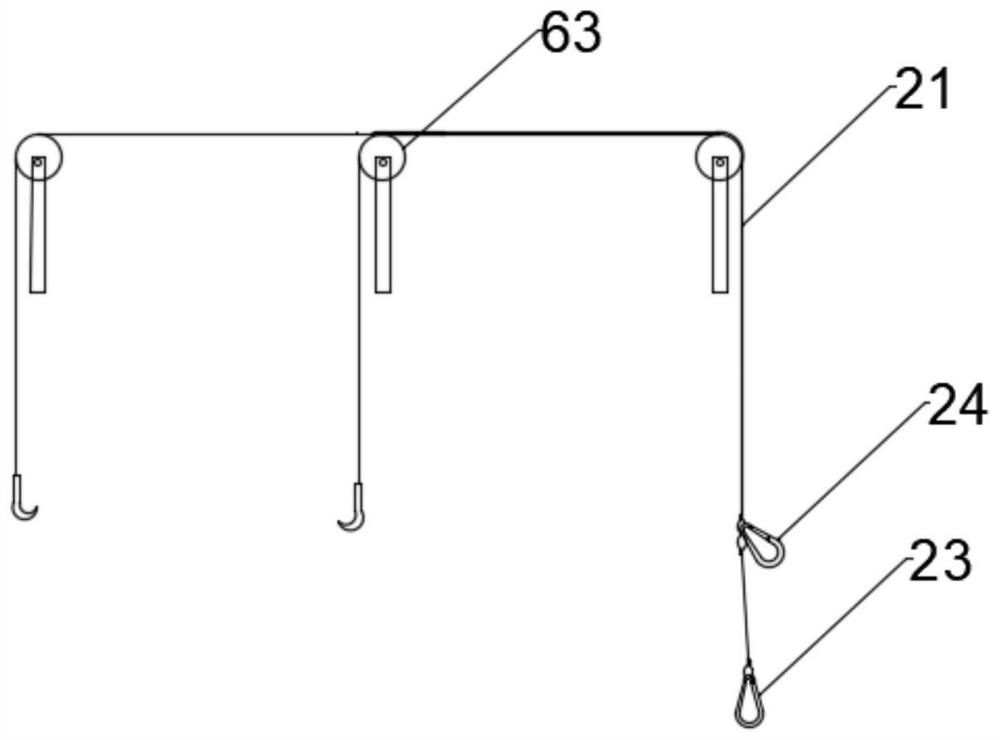

[0069] ① First determine whether the amount of filler in the upper power part 11 of the pressure mechanism 1 is sufficient, and its gravity should make the upper pressure spring 46 press to the exact design height, check whether there is filler in the lower power part 12, if there is no filler, use The upper cross bar 31 is in a horizontal state.

[0070] ②Fix the special latex film inside the cylinder 52. When placing it, try to keep the length of the latex film on both sides longer than the length of the cylinder 52 consi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com