Bilaterally pressurized three-axis sample preparation device

A triaxial sample and two-way pressurization technology, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problem of difficult sampling of sample cylinders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

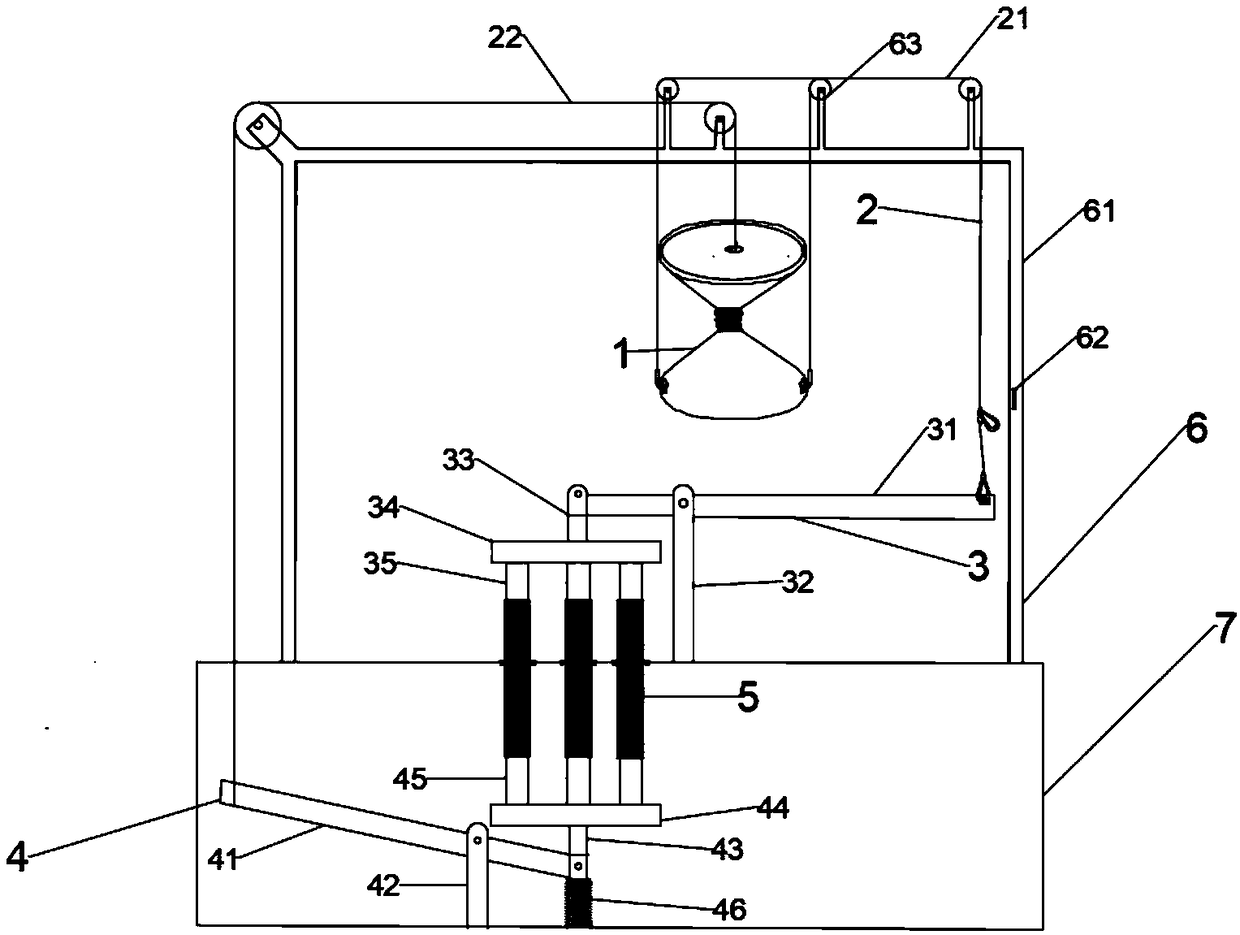

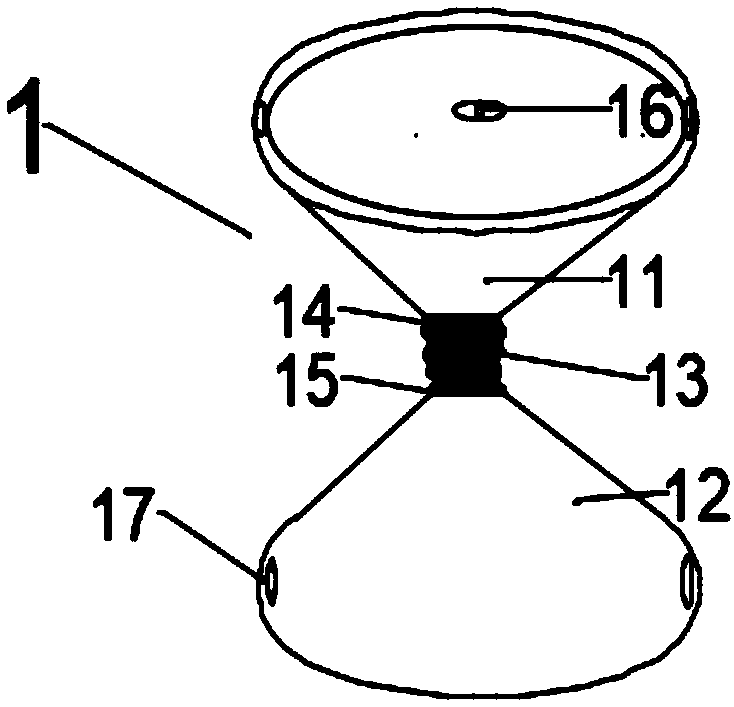

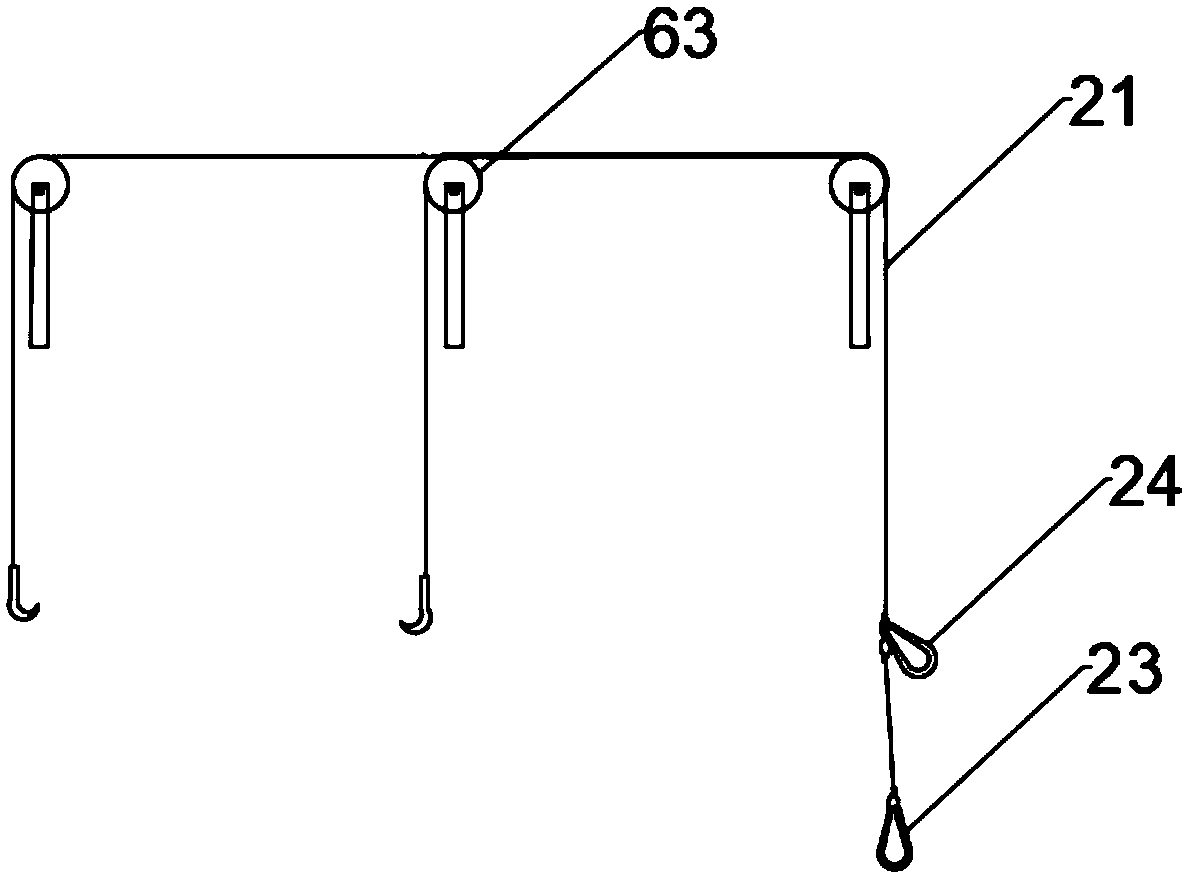

[0072] In this embodiment, a bidirectionally pressurized triaxial sample preparation device combines figure 1 , including pressure mechanism 1, pressure transmission mechanism 2, upper pressure mechanism 3, lower pressure mechanism 4, sample preparation cylinder 5 and multiple pulleys 63, pressure mechanism 1, upper pressure mechanism 2, sample preparation cylinder 5 and lower pressure mechanism The pressing mechanism 4 is arranged sequentially from top to bottom, and a plurality of pulleys 63 are fixedly arranged on the top of the pressing mechanism 1, combined with figure 2 , the pressure mechanism 1 includes an upper power part 11, a lower power part 12, an upper time controller 14, a lower time controller 15, the upper power part 11 and the lower power part 12 are connected by a soft conduit 13, and the bottom of the upper power part 11 is equipped with The upper time controller 14, the lower power part 12 and the upper time controller 14 corresponding positions are equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com