Method of automatically recognizing material pronging for bucket and method of automatically controlling shovel-loading for loader

An automatic identification and loader technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of large influence of vehicle speed changes, complicated curing parameter process, difficult to grasp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation will be described below in conjunction with the accompanying drawings.

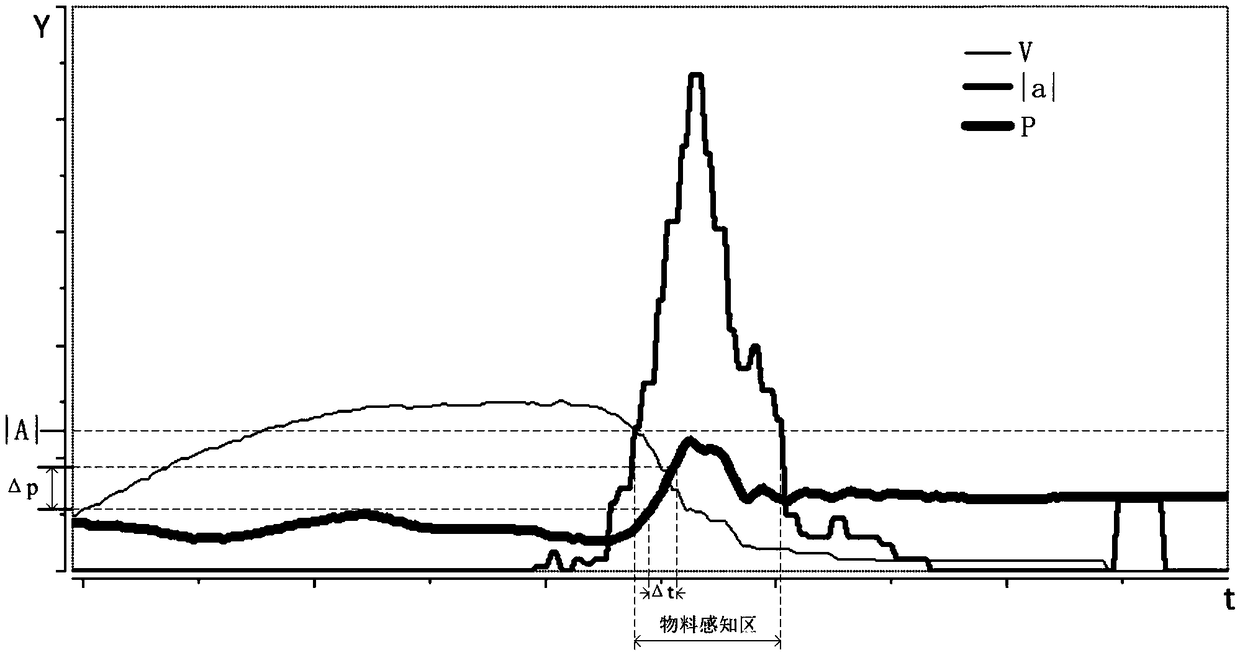

[0020] When the loader performs automatic shovel loading operation, firstly manipulate the machine to prepare for automatic shovel loading of the whole machine, so that the state of the loader conforms to the automatic shovel loading operation. After sensing and judging that the bucket of the loader is inserted into the material, the control system controls the loader to carry out the operation steps of loading the material into the bucket by shoveling. In the embodiment, the working device of the loader is a six-link front shovel working device.

[0021] The preparation work for the automatic shovel loading of the loader before shovel loading is basically fixed: including the adjustment operation of the bucket at levelling; the adjustment operation of the boom when the bucket is close to the ground; The braking system of the vehicle is in the non-braking state; and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com