Bionic vision detection system for surface defects of castings

A defect detection and casting technology, which is applied in the direction of optical defect/defect test, measuring device, material analysis through optical means, etc. It can solve the problems of low efficiency of manual detection, existence of blind spots, blurred images, etc., and achieve fast self-adaptive focusing Precise, easy to operate, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

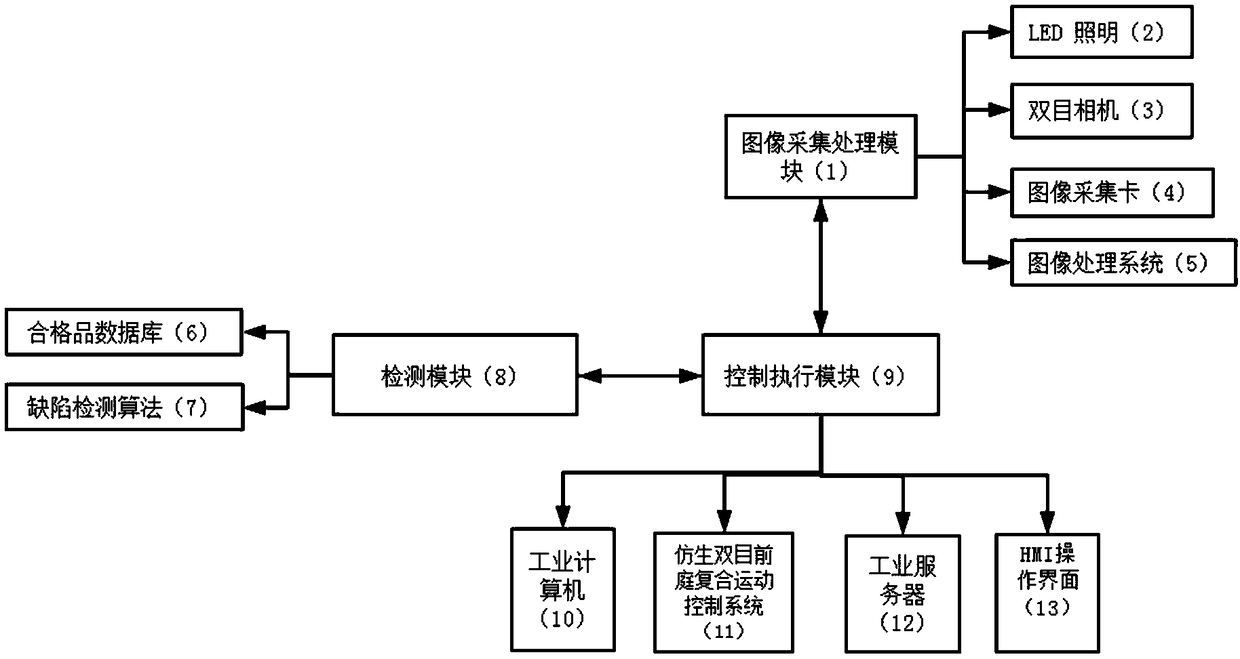

[0020] figure 1 It is a system module diagram, including an image acquisition and processing module (1), a detection module (8) and a control execution module (9). The image acquisition module (1) is composed of LED lighting (2), a binocular camera (3) using a liquid lens, an image acquisition card (4), and an image processing system (5), and the detection module (8) consists of The qualified product database (6) and the defect detection algorithm (7) are composed; the control execution module (9) is operated by an industrial computer (10), a bionic dual-forest compound motion control system (11), an industrial server (12) and an HMI The interface (13) is composed.

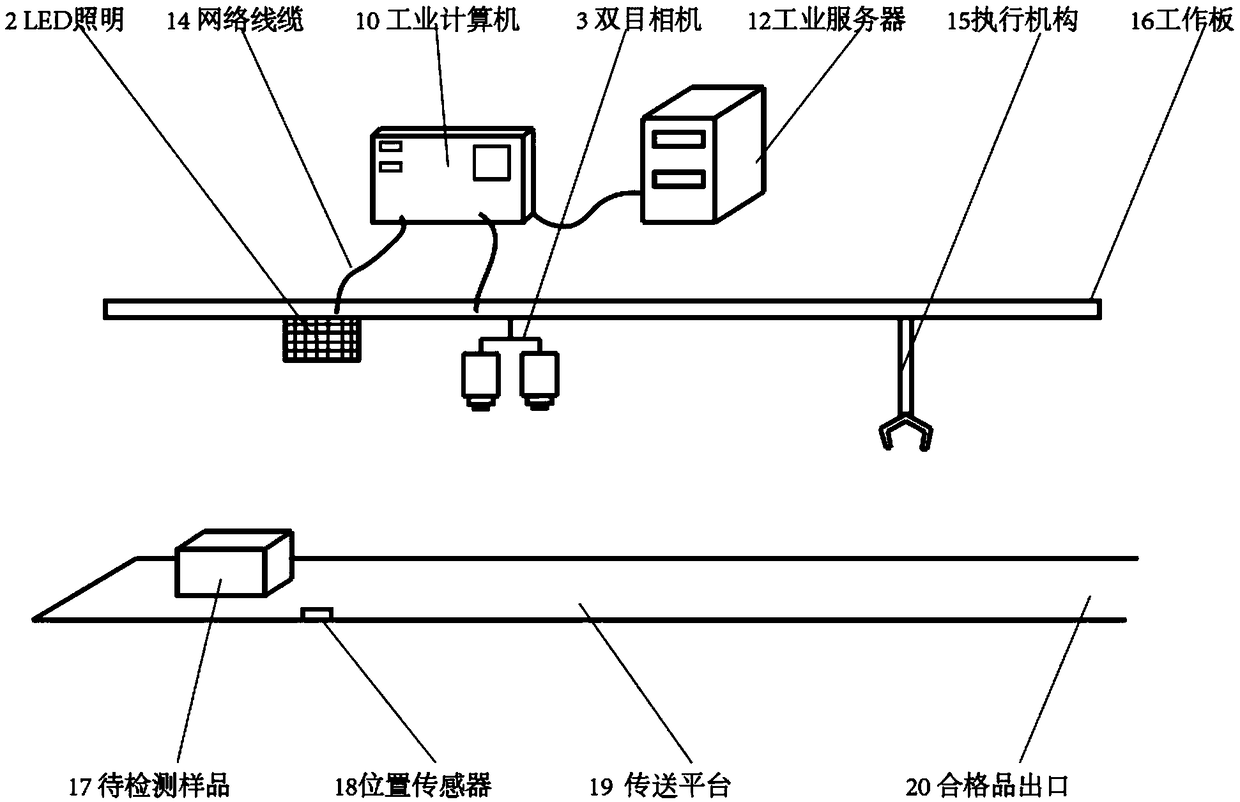

[0021] figure 2 It is a schematic diagram of the hardware structure of the detection process, and the detection process hardware includes: LED lighting (2), network cables (14), indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com