Pixel structure and manufacturing method thereof

A technology of pixel structure and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems affecting the display contrast display effect of the display panel, lateral leakage current, etc., to optimize the display effect, prevent short-circuit phenomenon, and expand the deposition area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

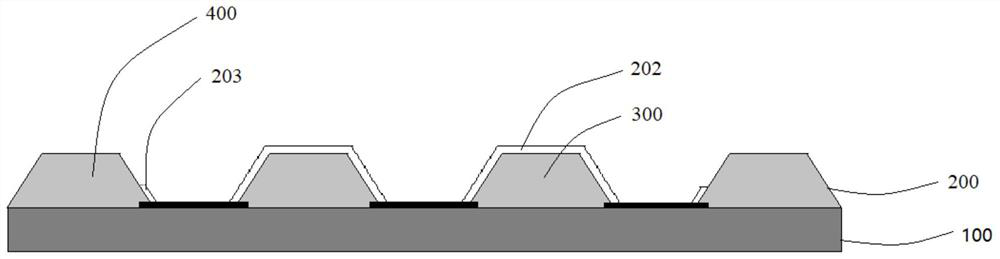

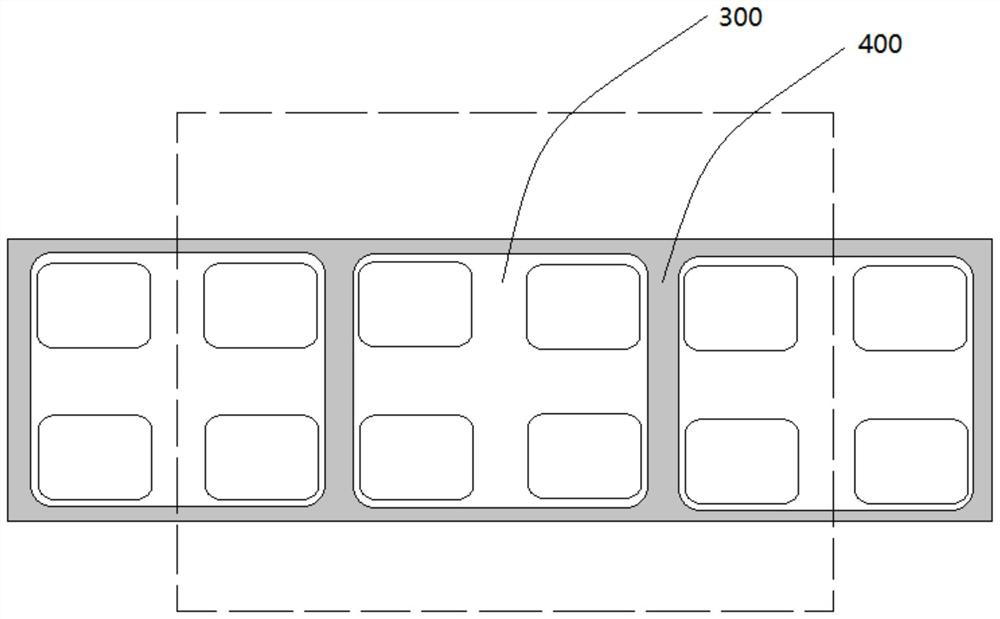

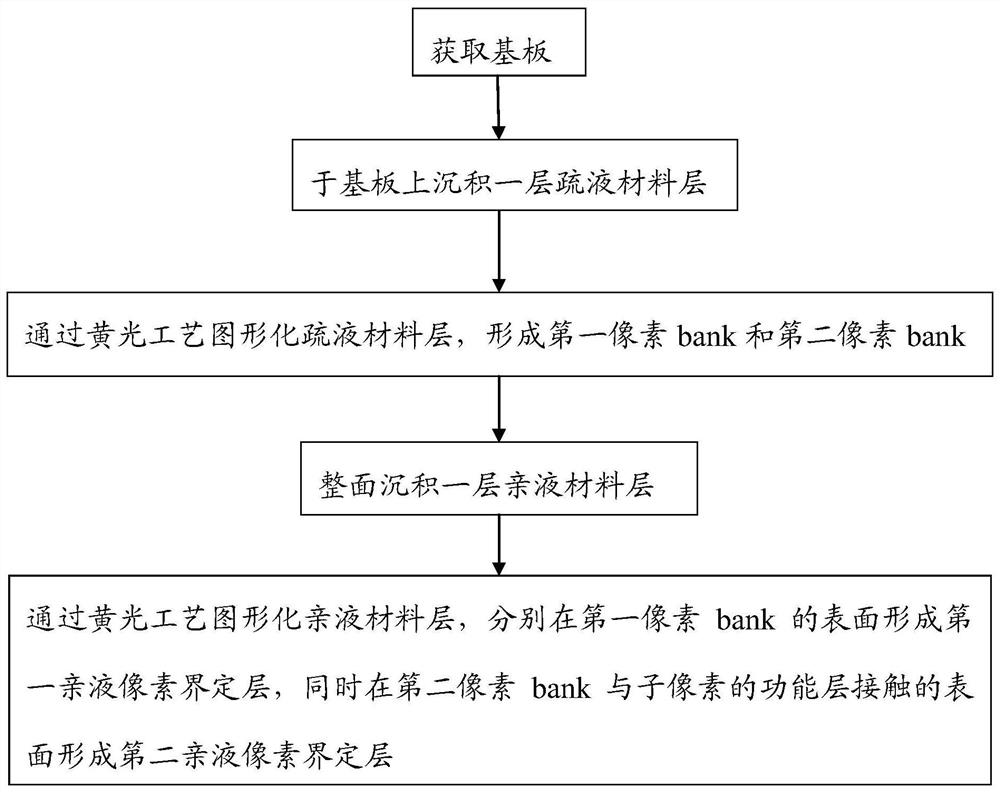

[0037] In this embodiment, a pixel structure, such as figure 1 and 2 shown, including:

[0038] Substrate 100;

[0039] The pixel defining layer 200 stacked on the substrate 100; the pixel defining layer 200 includes a first pixel bank300 and a second pixel bank400, and a plurality of sub-pixels surrounded by the first pixel bank300 and the second pixel bank400 corresponding to each sub-pixel pixel cavities; the pixel cavities on both sides of the first pixel bank300 are used to set sub-pixels with the same color, and the pixel cavities on both sides of the second pixel bank400 are used to set sub-pixels with different colors;

[0040] The surface of the first pixel bank 300 is provided with a first lyophilic pixel defining layer 202 . It can be understood that, in other embodiments, the first pixel bank 300 may also be entirely made of lyophilic materials, so that the surface thereof only needs to be lyophilic.

[0041] In the above pixel structure, the first lyophilic pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com