Rotor magnetic steel

A magnetic steel and rotor technology, applied in the direction of magnetic circuit, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of motor failure, low efficiency of magnetic tile installation, increased labor intensity of workers, etc., to achieve Improve installation efficiency and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

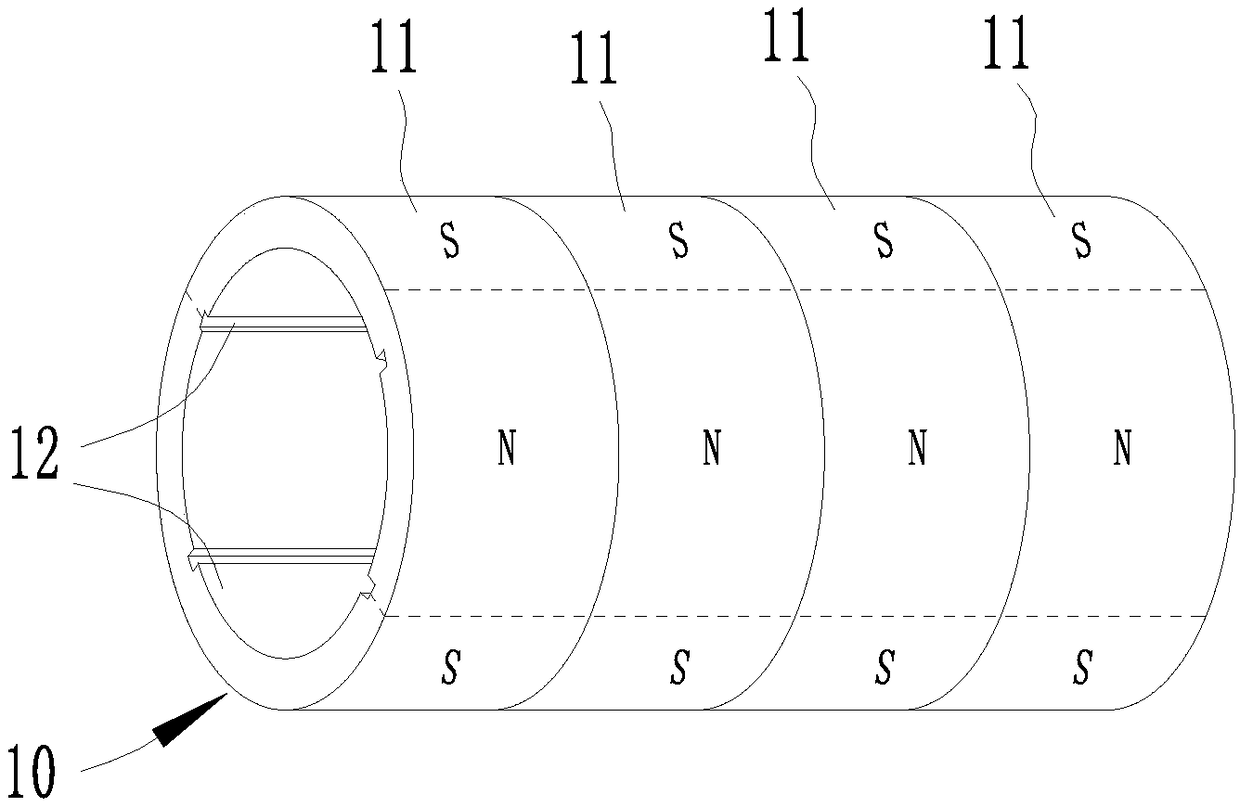

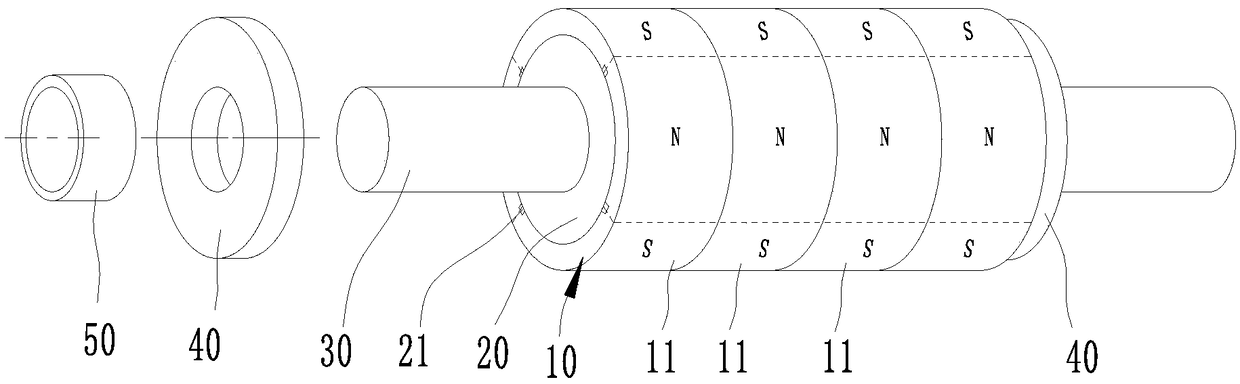

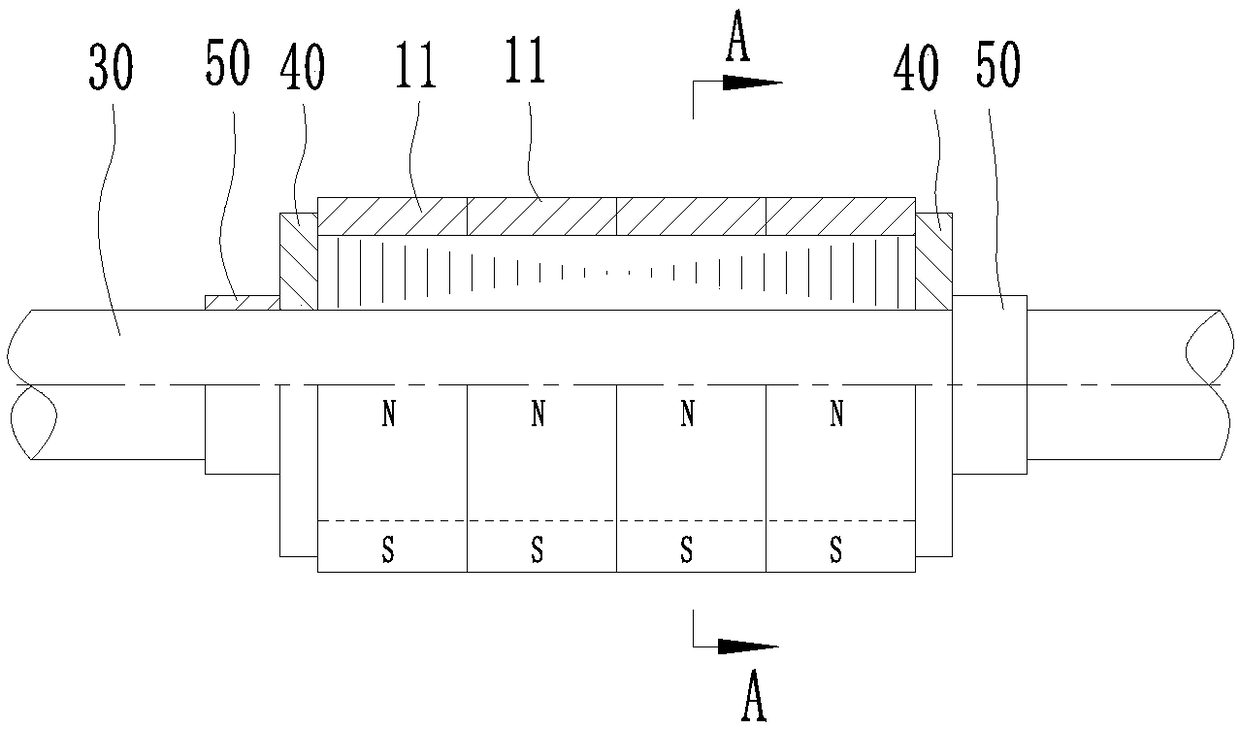

[0011] A rotor magnet, comprising an annular magnet unit 11 , at least two axial end surfaces of the magnet unit 11 are arranged in close contact with each other to form a tubular magnet body 10 .

[0012] The worker directly sets the ring-shaped magnetic steel unit 11 onto the rotor core 20 in turn, which is convenient for the worker to operate and improves the installation efficiency of the magnetic steel body 10. The application can arrange a corresponding number of magnetic steel units according to the different axial lengths of the rotor core 20. The magnetic steel unit does not need additional design and manufacture of magnetic steel. In addition, the magnetic steel body cannot fall off even on high-speed motors.

[0013] In order to effectively limit the circumferential rotation of the magnetic steel unit 11, a limiting groove 12 is provided on the inner wall of the annular magnetic steel unit 11, and the groove length direction of the limiting groove 12 is consistent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com