Gripper sucker for overturning and carrying automobile hubs

A technology of automobile hubs and suction cups, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as shedding, damage to the surface of the hub, and large volume of the hub, and achieve the effect of increasing hardness and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

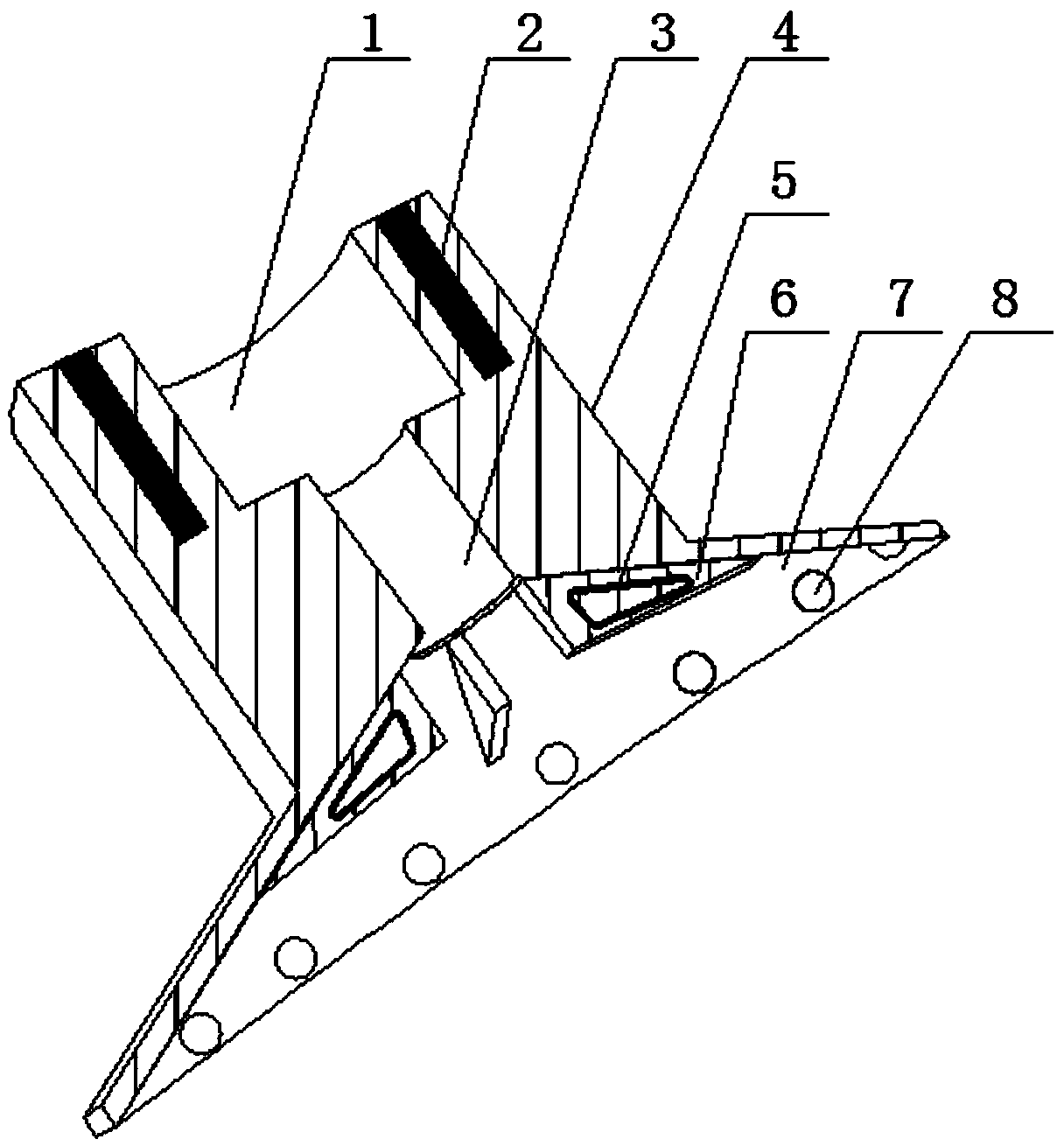

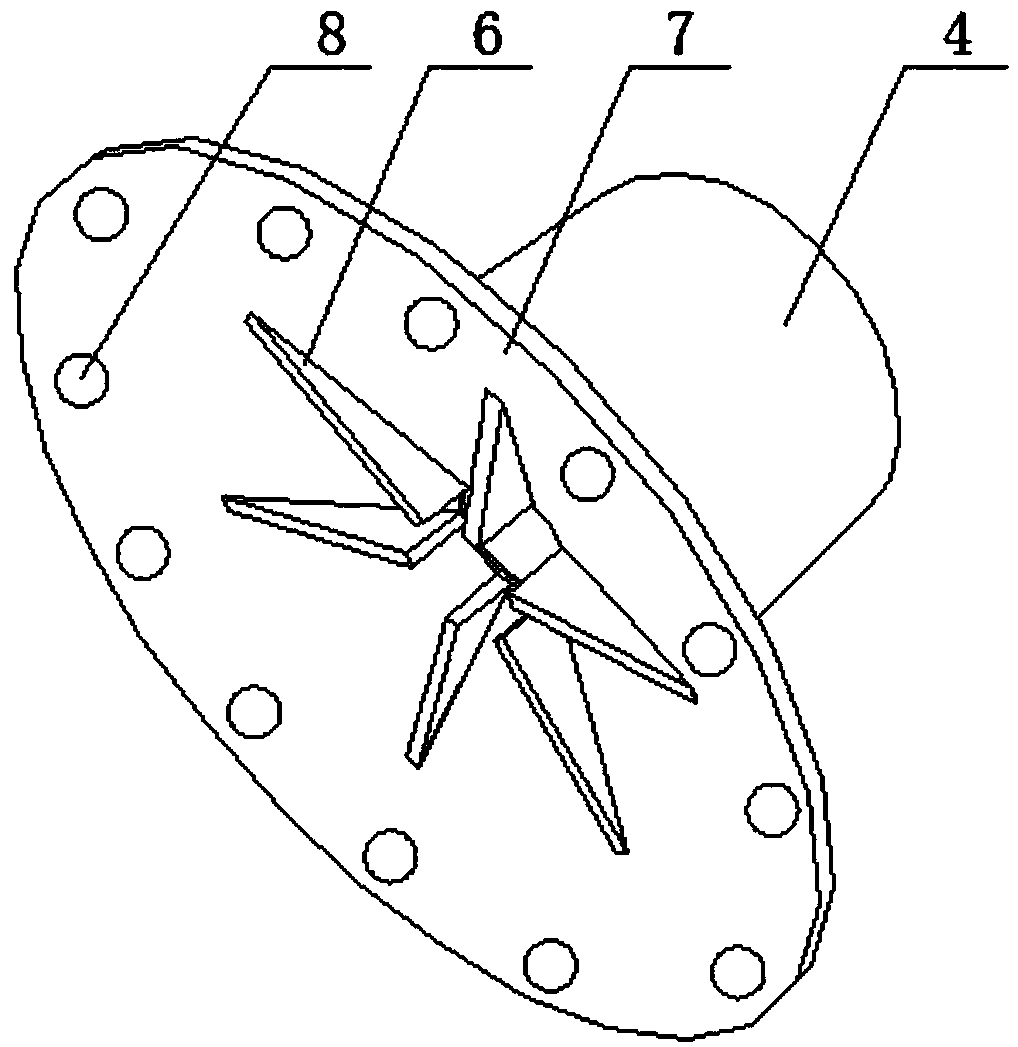

[0019] A gripper suction cup for turning and transporting automobile wheels, comprising a suction cup body, the suction cup body includes a suction cup bottom 7 integrally made of silicon rubber material and a connecting booster neck 4, the connecting booster neck is coaxially formed on the bottom of the suction cup On the upper end, a manipulator fixing hole 1 and a booster channel 3 are coaxially arranged in the connection booster neck. In order to make the installation more compact, a metal ring piece 2 is arranged in the side wall of the connection booster neck corresponding to the manipulator fixing hole, adding The hardness of the connecting booster neck prevents the connecting booster neck from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com