A waterproof roll packaging machine capable of quickly changing rolls

A technology for waterproofing membranes and packaging machines, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of messy integrated circuit lines, troublesome repair and maintenance, machine working deviation, etc., to achieve simple structure, easy maintenance, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

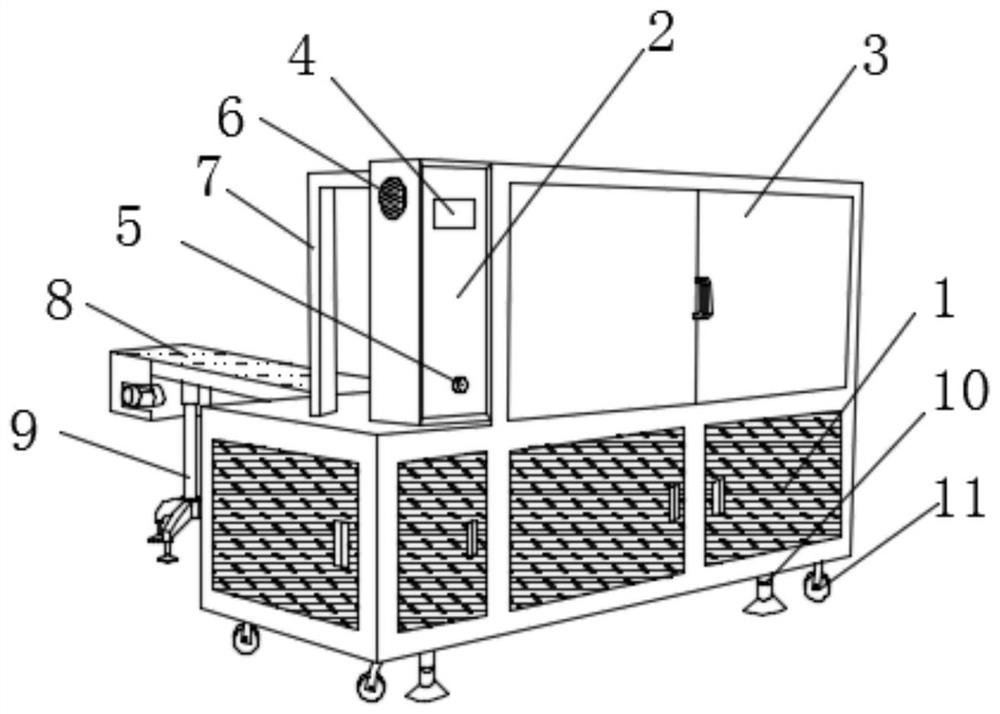

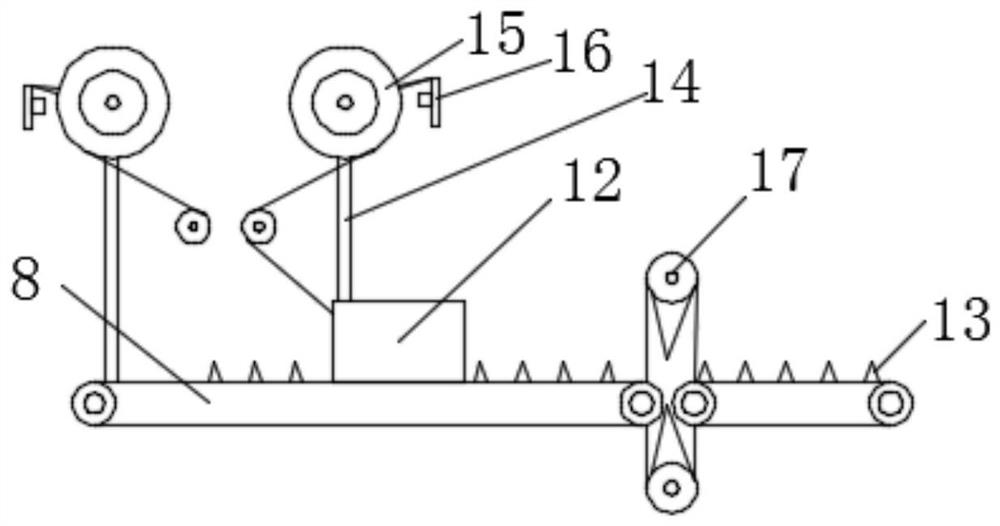

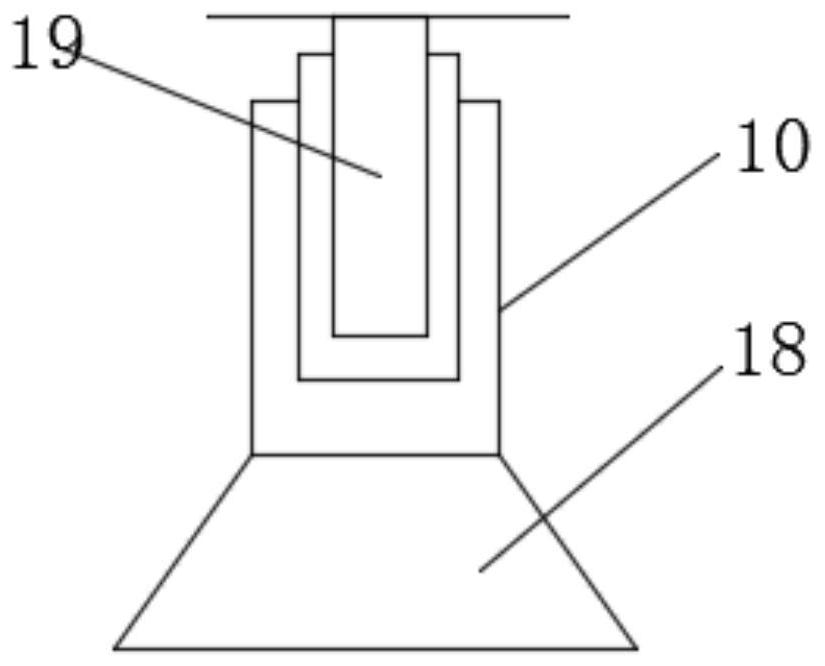

[0024] The first embodiment: see Figure 1-Figure 4 As shown, the present invention provides a waterproof roll packaging machine that can quickly replace rolls, including: a storage cabinet 1, a control box 2 and a glass door 3 are fixedly installed on the outer surface of the upper end of the storage cabinet 1, and the control box 2 is located on one side of the glass door 3, a touch screen 4 and a switch button 5 are fixedly installed on the outer surface of the front end of the control box 2, and the touch screen 4 is located above the switch button 5, and one side of the control box 2 An exhaust hole 6 is fixedly installed on the upper end of the outer surface, a stabilizer 7 is fixedly installed on the outer surface of the rear end of the glass door 3, a conveyor belt 8 is fixedly installed on the outer surface of the rear end of the storage cabinet 1, and the rear end of the conveyor belt 8 A support rod 9 is fixedly installed on the outer surface of the end side, and an...

no. 2 approach

[0028]The second embodiment: a waterproof coil packaging machine that can quickly replace rolls, including: a storage cabinet 1, a control box 2 and a glass door 3 are fixedly installed on the outer surface of the upper end of the storage cabinet 1, and the control box 2 is located at On one side of the glass door 3, a touch display screen 4 and a switch button 5 are fixedly installed on the outer surface of the front end of the control box 2, and the touch display screen 4 is located above the switch button 5, and the outer surface of one side of the control box 2 An exhaust hole 6 is fixedly installed on the upper end, a stabilizing frame 7 is fixedly installed on the outer surface of the rear end of the glass door 3, and a conveyor belt 8 is fixedly installed on the outer surface of the rear end of the storage cabinet 1, and the rear end of the conveyor belt 8 is fixed. A support rod 9 is fixedly installed on the side outer surface, an oil presser foot 10 and a universal whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com