Oil skimmer

A technology of oil skimmer and oil level, which is applied in chemical instruments and methods, grease/oily substance/floating matter removal devices, control/manipulation systems, etc. It can solve the problem that oil easily blocks pipelines, affects water quality, reduces Dissolved oxygen content in water and other issues, to avoid burning or leakage hidden dangers, improve the use of safety performance, improve the effect of layering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be made below in conjunction with drawings and embodiments.

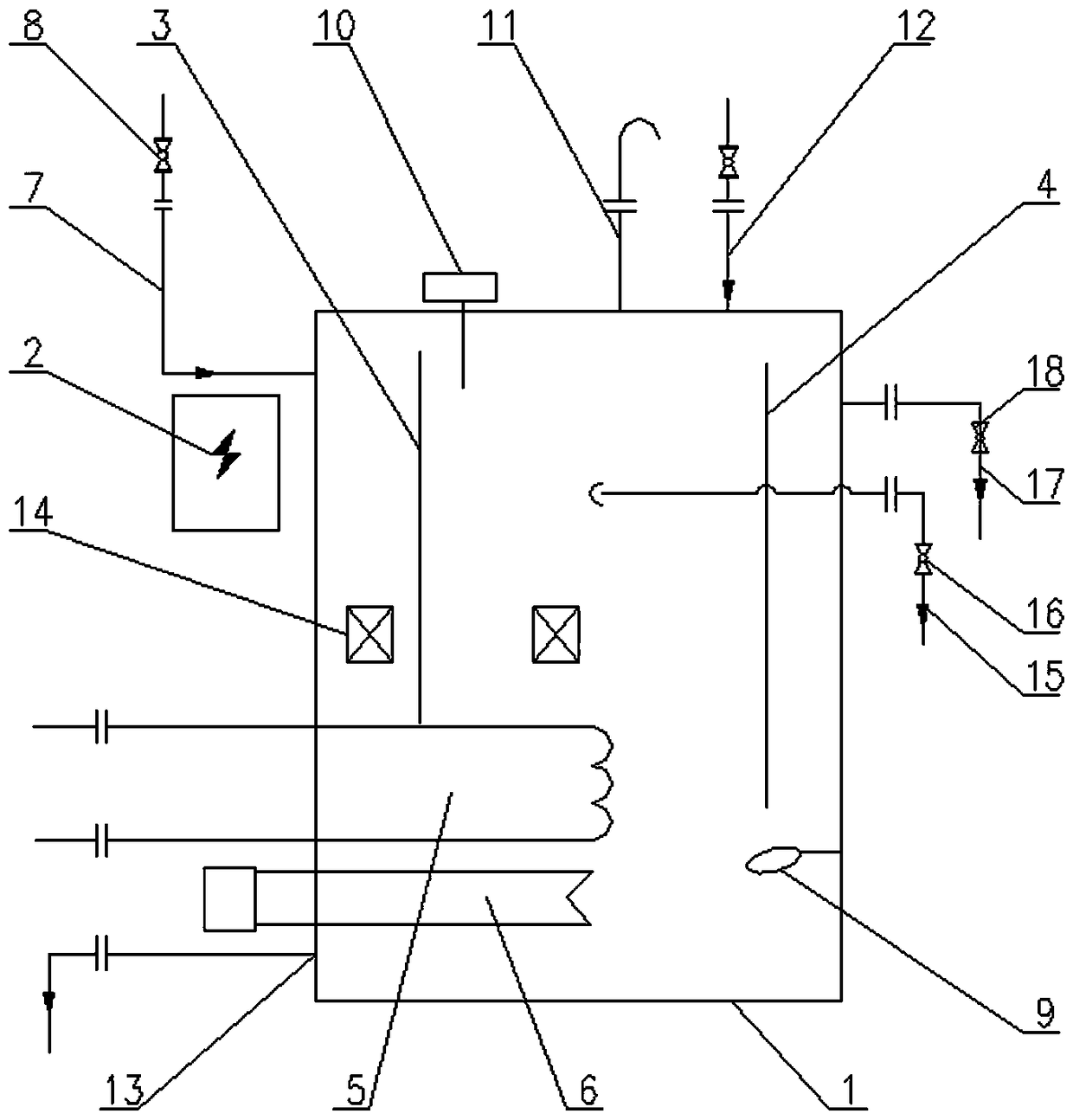

[0015] figure 1 Shown: an oil skimmer, the box 1 is divided into the first, second and third chambers connected up and down by the left partition 3 and the right partition 4, and the upper part of the first chamber of the box 1 is externally connected to the The kitchen gray water pipe 7 of the water valve 8, the steam heating coil 5 and the electric heater 6 are arranged at the connection between the bottom of the first and second chambers, the liquid level switch 9 is arranged above the electric heater 6, and the bottom side wall of the box body 1 is provided with A discharge port 13, a temperature control 14 is provided in the first and second chambers, a liquid level electrode 10, a vent 11 and a flushing water port 12 are arranged on the upper part of the second chamber, and the liquid level electrode 12 extends into the second chamber. The inside of the chamber is lower than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com