Pendulum torsional-vibration reducing device

A torsional vibration, vibrator-type technology, used in transmission, rotational vibration suppression, fluid transmission, etc., can solve the problems of reduced vibration damping performance, increased cost, longer shaft length, etc., to suppress bending or buckling, improve The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

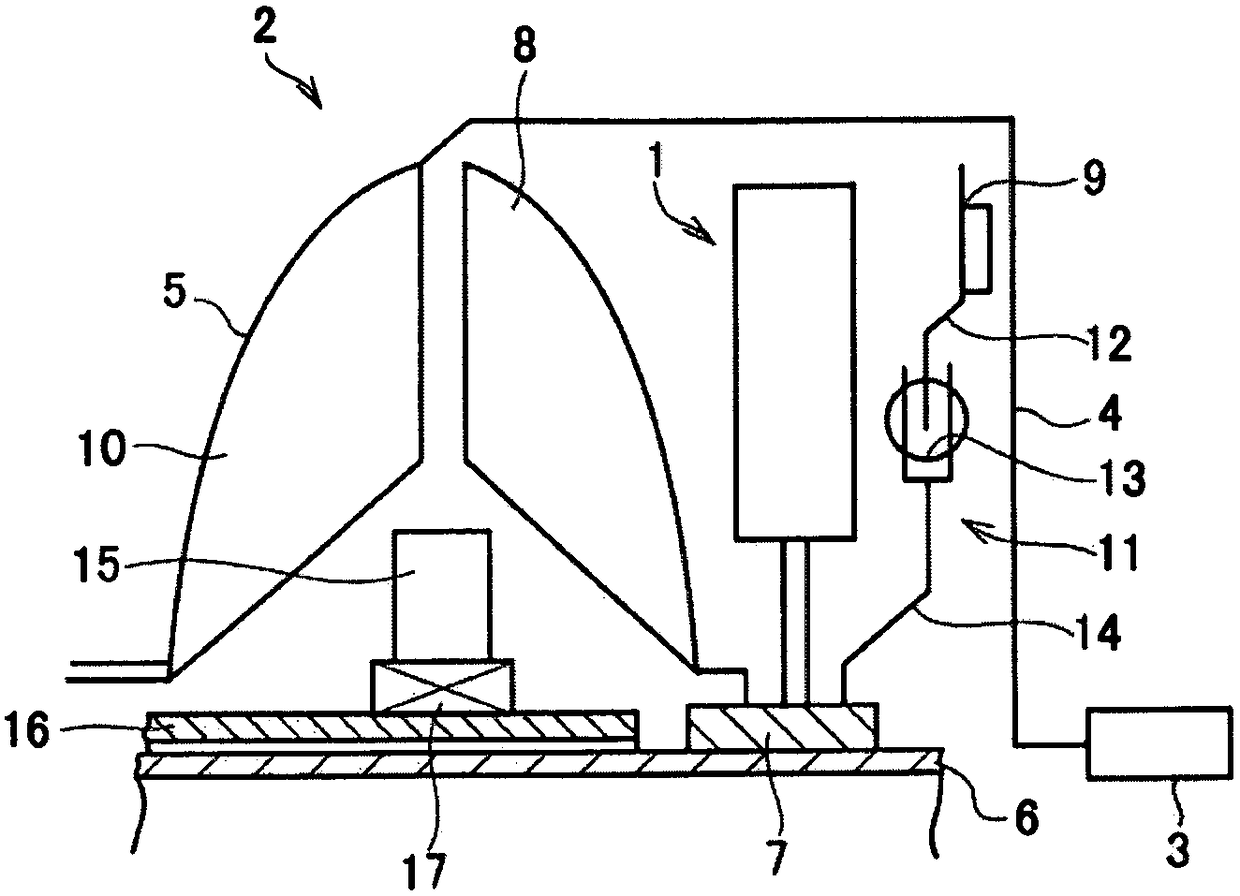

[0021] Hereinafter, the present invention will be specifically described with reference to the drawings. Vibrator type torsional vibration reducing device 1 according to the present invention, such as figure 1 As shown, it is built in the torque converter 2. Next, the structure of the torque converter 2 will be briefly described. The front cover 4 connected to the engine 3 and the pump casing 5 are integrated to form an integral casing of the torque converter 2 . The input shaft 6 of the speed change mechanism is arranged along the central axis of the housing. On the outer peripheral portion of the input shaft 6, a turbine hub 7 is integrally and rotatably provided. A turbine wheel 8 , a lock-up clutch 9 , and a vibrator-type torsional vibration reduction device 1 are connected to the turbine hub 7 .

[0022] The turbine impeller 8 is arranged to face the pump impeller 10 , and receives the oil flow from the turbine impeller 10 to rotate. In addition, the lock-up clutch 9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap