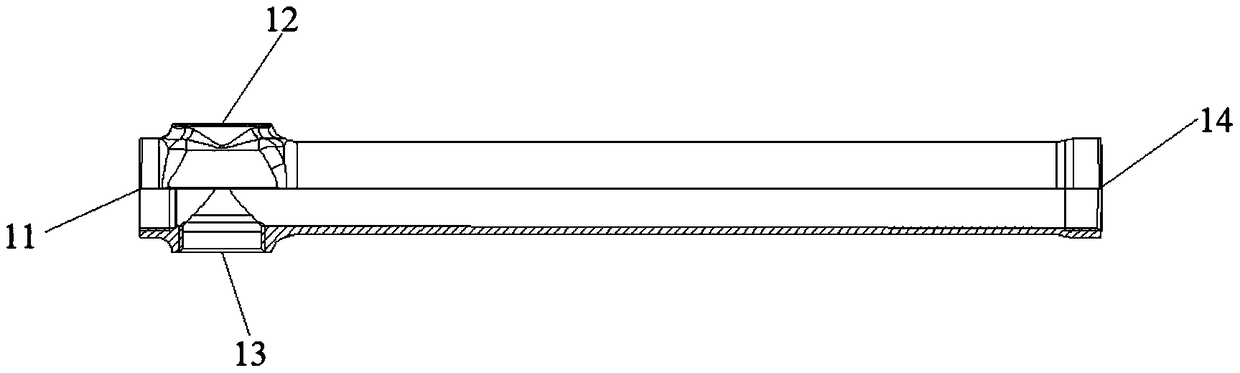

Power divider

A power splitter and rod splitter technology, which is applied to waveguide devices, electrical components, connecting devices, etc., can solve the problems of high production cost, complex processing technology of power splitters, and low assembly efficiency, so as to optimize the processing and production process, Improve product delivery speed, reduce cost and capital effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

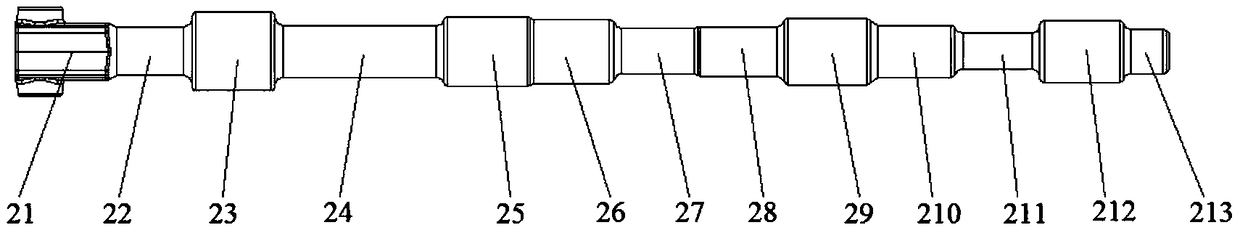

[0023] Such as figure 2 and Figure 4As shown, the diameter of the first-stage impedance transformation section 21 is set to 7mm, and the length is set to 11.5mm, the diameter of the second-stage impedance transformation section 22 is set to 6mm, and the length is set to 10.3mm, and the third stage The diameter of the impedance transformation section 23 is set to 9.7mm, and the length is set to 10.3mm. The diameter of the fourth-stage impedance transformation section 24 is set to 6.4mm, and the length is set to 20.9mm. The diameter of the fifth-stage impedance transformation section 25 Set to 8.5mm, the length is set to 10.7mm, the diameter of the sixth impedance transformation section 26 is set to 7.9mm, the length is set to 10.4mm, the diameter of the seventh impedance transformation section 27 is set to 5.6mm, the length Set to 10.5mm, the diameter of the eighth stage impedance transformation section 28 is set to 6.1mm, the length is set to 10.7mm, the diameter of the nin...

Embodiment 2

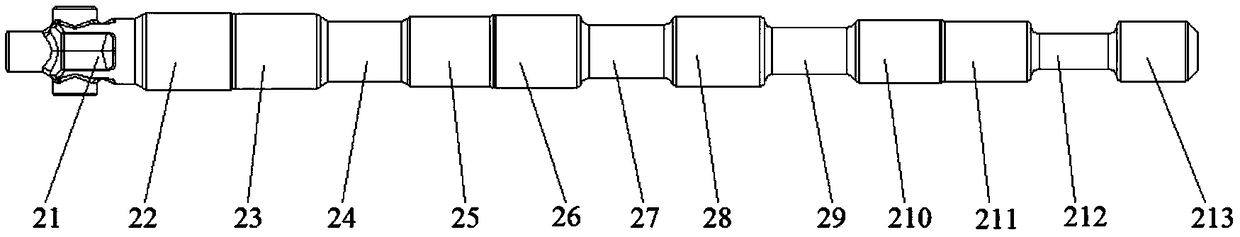

[0025] Such as image 3 and Figure 5 As shown, the diameter of the first stage impedance transformation section is set to 8.2mm, and the length is set to 11.4mm, the diameter of the second stage impedance transformation section is set to 9.6mm, and the length is set to 11.2mm, and the third stage The diameter of the impedance transformation section is set to 9.2mm, the length is set to 11mm, the diameter of the fourth-stage impedance transformation section is set to 7.5mm, the length is set to 10.8mm, and the diameter of the fifth-stage impedance transformation section is set to 8.6mm , the length is set to 10.8mm, the diameter of the sixth-stage impedance transformation section is set to 9.1mm, and the length is set to 10.8mm, the diameter of the seventh-stage impedance transformation section is set to 6.6mm, and the length is set to 11.4mm, the The diameter of the eighth stage impedance transformation section is set to 8.7mm, and the length is set to 11.5mm, the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com