A process method for group welding of diffuser tubes in marine diesel engines

A technology of marine diesel engine and process method, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of damage to turbochargers, deformation of top and bottom flanges, dust inhalation of turbochargers, etc. problems, to achieve the effect of solving large deformation and solving errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] A process method for welding a diffuser tube in a marine diesel engine, comprising the following steps:

[0040] Step 1: Pre-install the scavenging box 05 and the turbocharger 04 and assemble them in place;

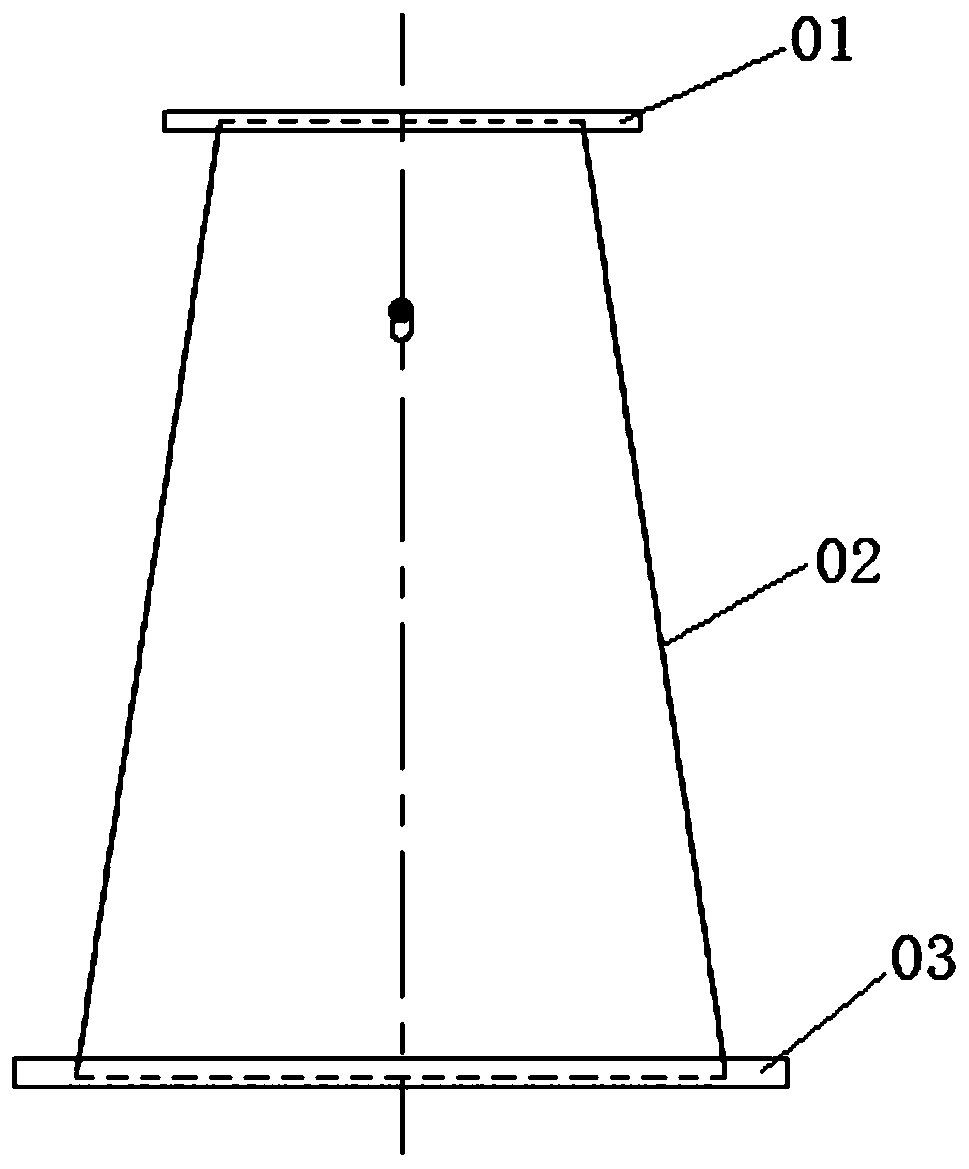

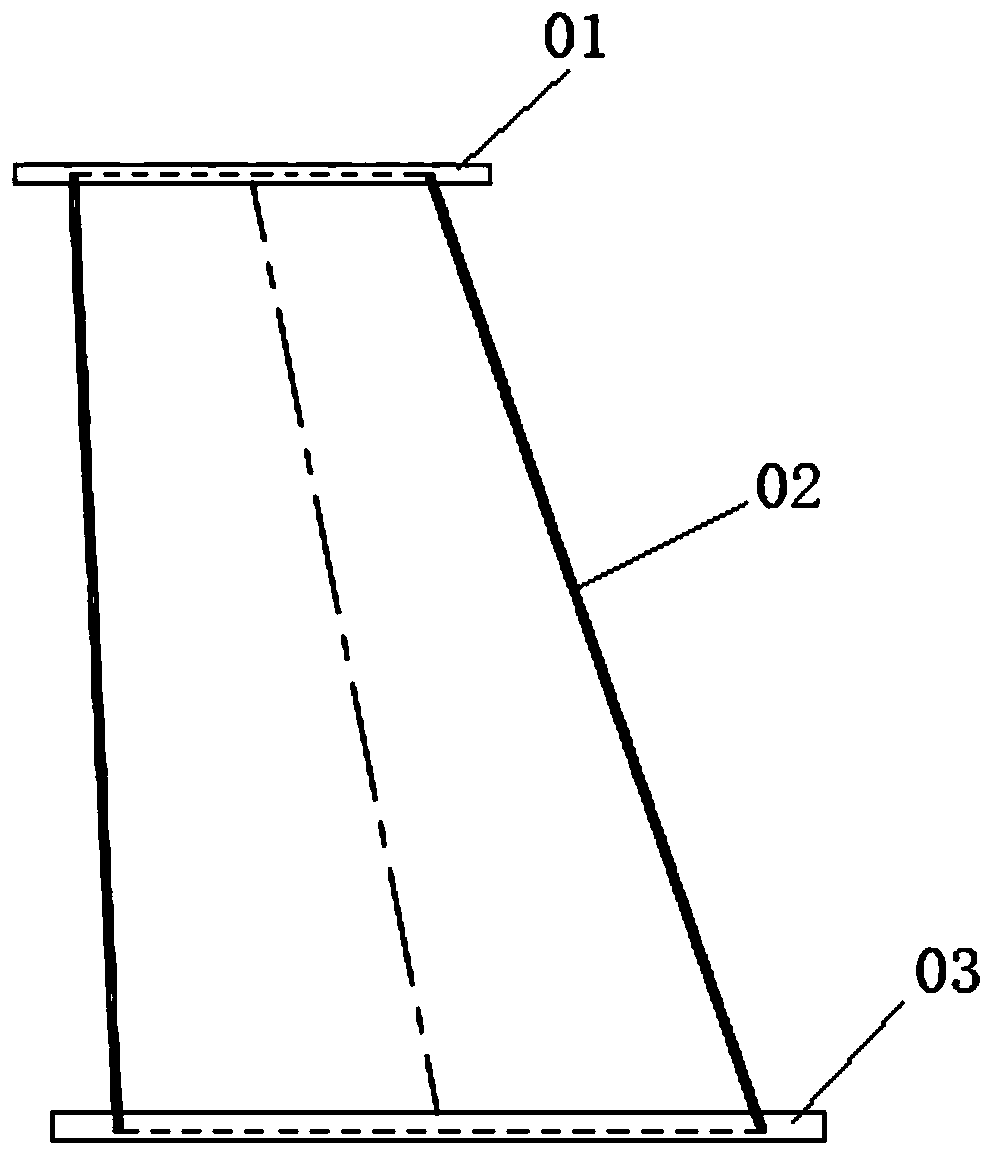

[0041] Step 2: Pre-assemble the top flange 01 of the diffuser tube 0 and the turbocharger 04 to position the top flange 01, and pre-assemble the bottom flange 03 of the diffuser tube 0 and the scavenging box 05 Equipped with the positioning of the bottom flange 03, where the connection between the turbocharger 04 and the top flange 01 is provided with an expansion joint 2;

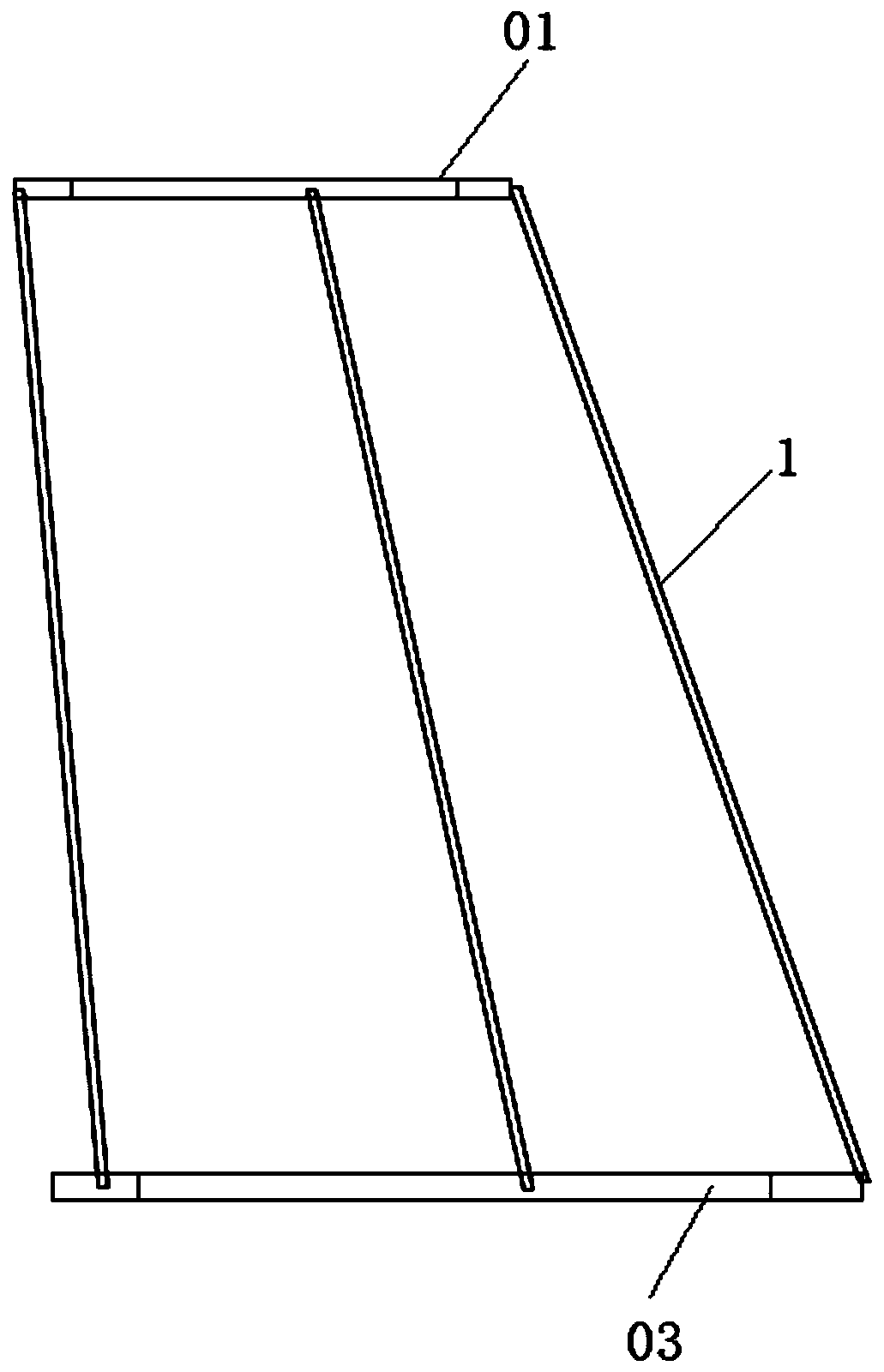

[0042] Step 3: Use several positioning ribs 1 to weld the outer edges of the top flange 01 and the bottom flange 03, such as image 3 As shown, complete the matching connection between the top flange 01 and the bottom flange 03 in the diffuser tube 0;

[0043] Step 4:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com