Hazardous chemical substance warehouse-in and warehouse-out carrying method, system and equipment based on AGV forklift and medium

A technology for entering and exiting warehouses and dangerous chemicals, which is applied in the field of intelligent warehouses, can solve the problems of lack of information means and the inability to display goods intuitively to managers, etc., achieve rapid positioning and search, speed up the speed of entering and exiting warehouses, and solve the problem of difficult to find goods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

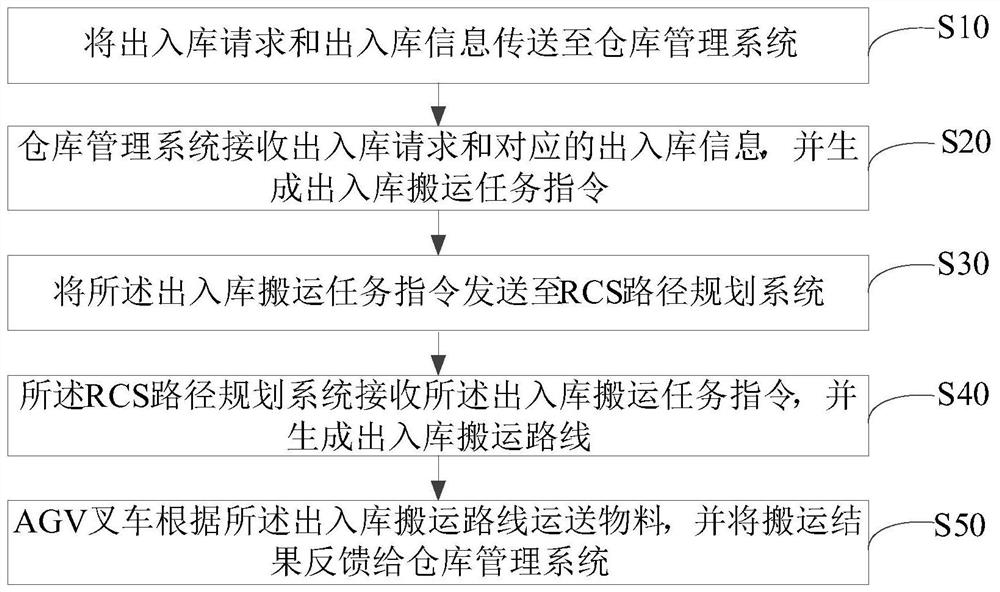

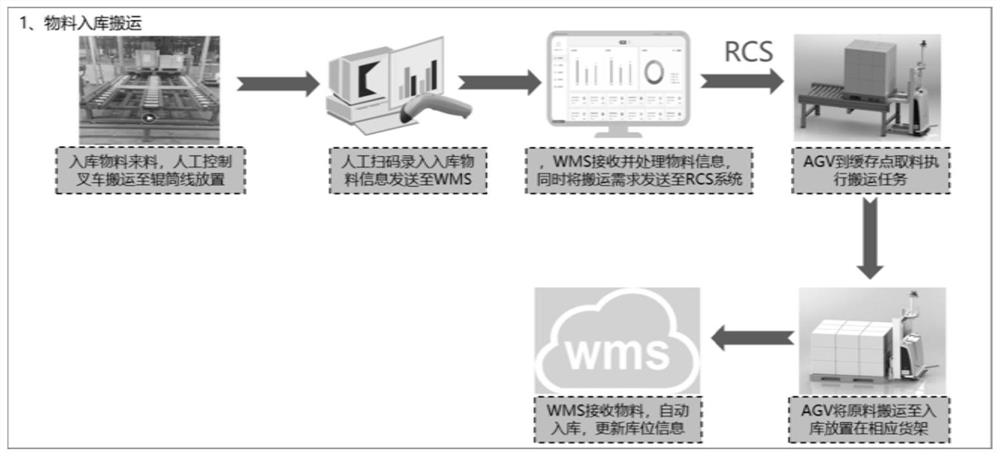

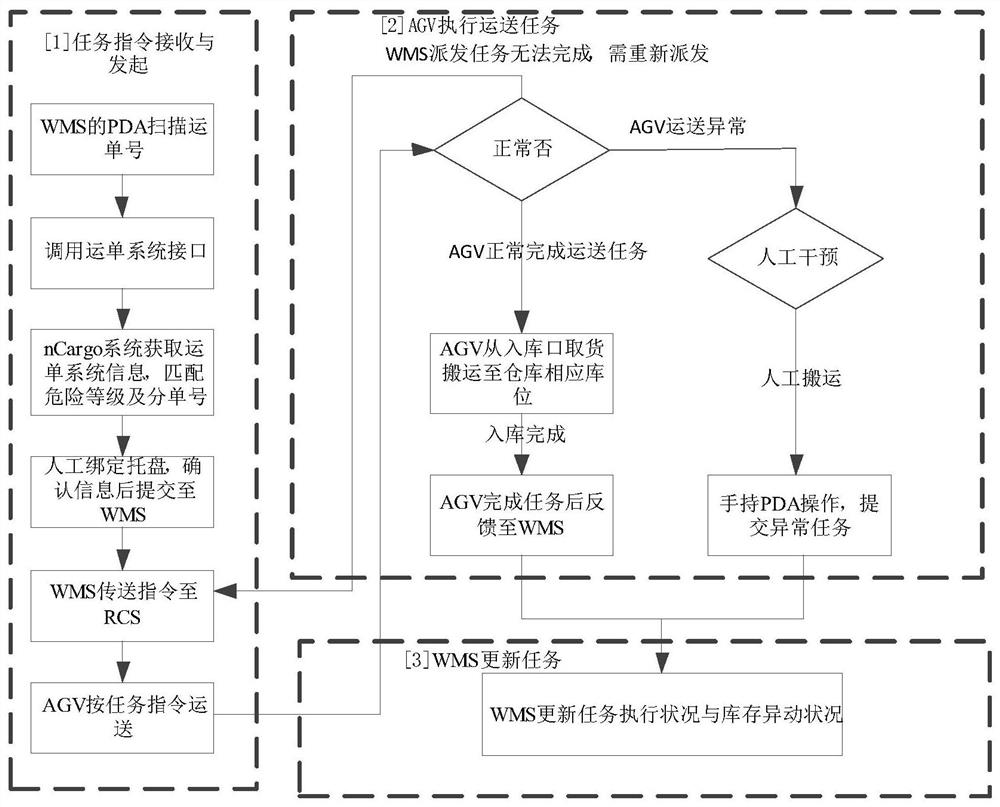

Method used

Image

Examples

Embodiment Construction

[0048] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0049] In the prior art, manually driven forklifts are used to complete the entry and exit operations of goods in the hazardous chemical warehouse, and the manual driving forklifts are used to carry goods, resulting in low efficiency in finding goods, limited speed of entry and exit, and low production efficiency of the entire warehouse. At the same time, There are many corrosive, explosive and flammable goods in the hazardous chemical warehouse, and there are still many uncertain dangers in the operation of personnel drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com