Method for preparing hypoallergenic whey proteins by cysteine-bound transglutaminase modification

A technology of transglutaminase and cysteine, which is applied in protein food processing, animal protein processing, protein food ingredients, etc., can solve the problems of high temperature and other reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

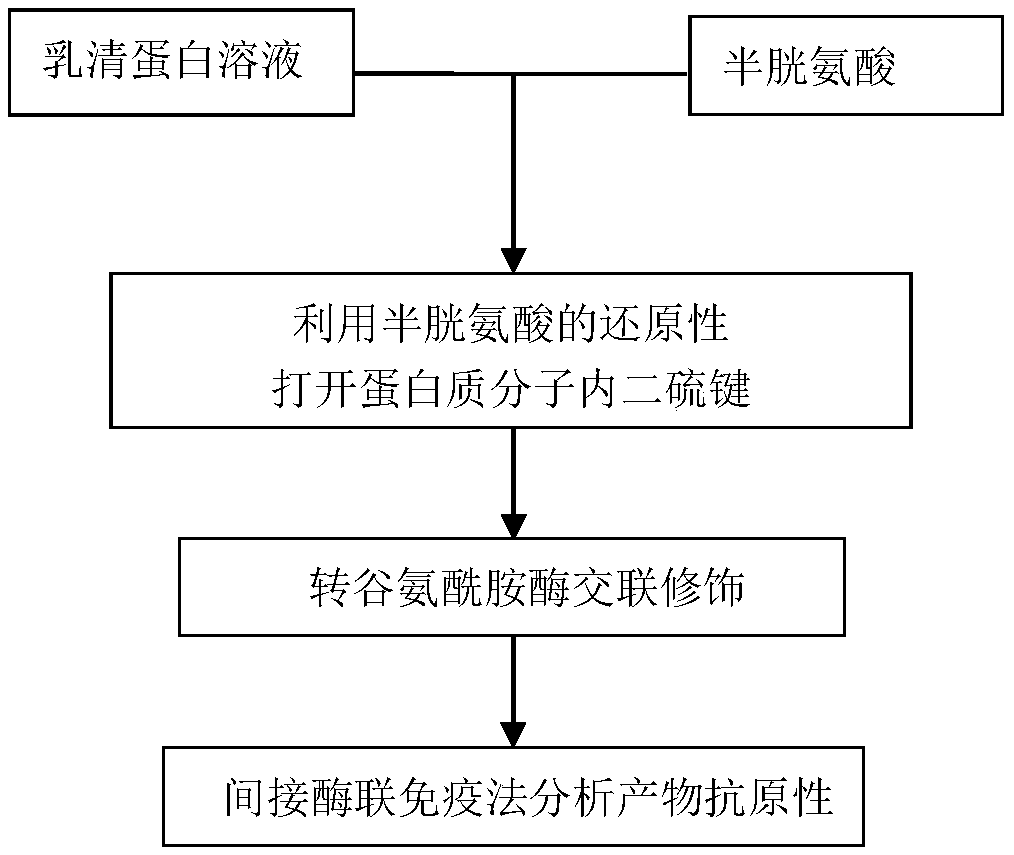

Method used

Image

Examples

Embodiment 1

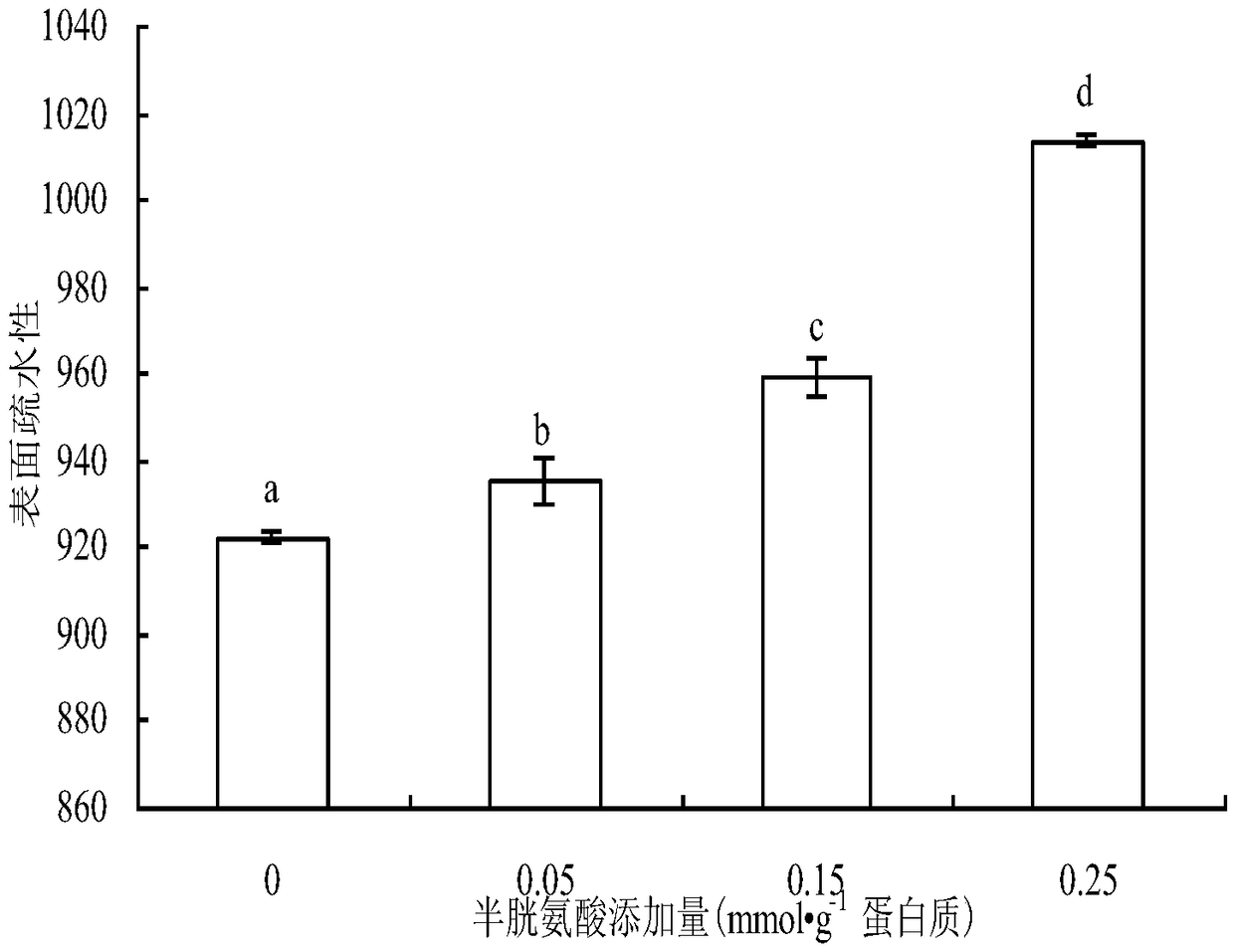

[0023] (1) Preparation of cysteine solution: solid cysteine at 0.1mol L -1 Dissolve in HCl, after the dissolution is complete, use 0.05mol·L -1 NaOH was adjusted to pH 7.0, and sealed for storage until use.

[0024] (2) Add the cysteine solution prepared in step (1) to 0.05mmol·g -1 The amount of protein added to the whey protein solution, the concentration of whey protein is 30g L -1 , pH 7.0, and treated in a water bath at 37°C for 30 minutes.

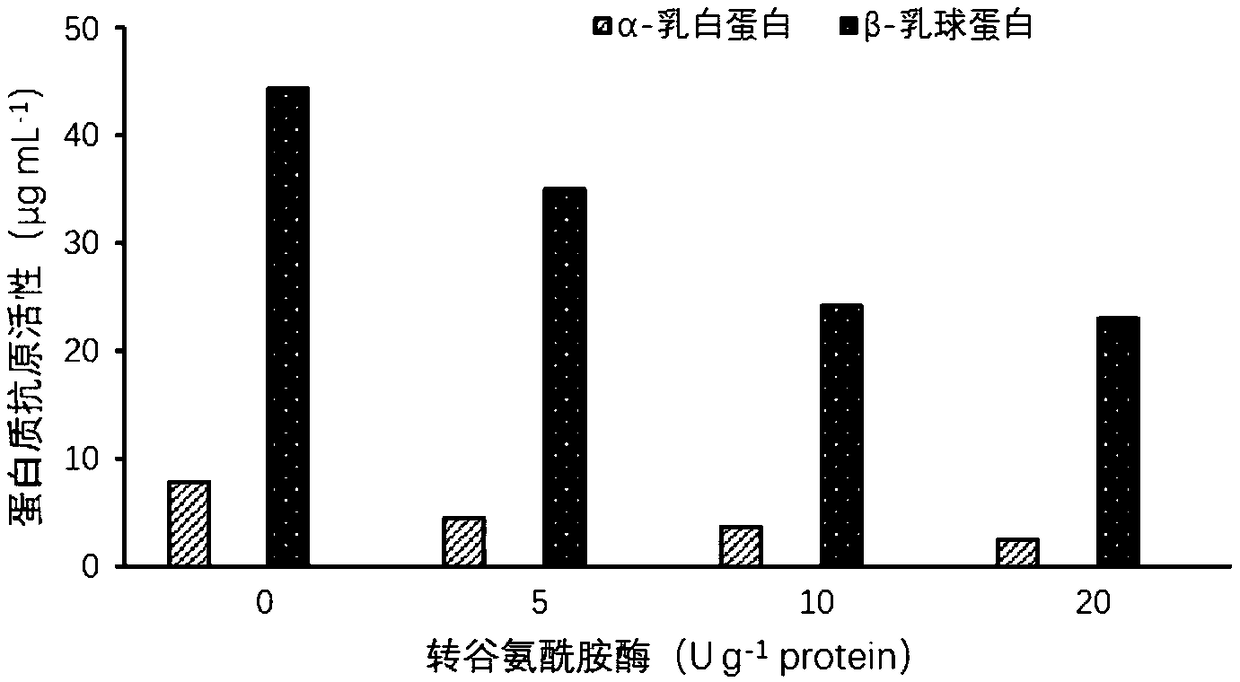

[0025] (3) Add 3U·g to the sample treated in step (2) -1 1. For protein transglutaminase, react in a water bath at 37°C for 2h, inactivate the enzyme at 85°C for 10min after the reaction, take it out and cool to room temperature. Using untreated raw whey protein as a control sample, the content of α-lactalbumin and β-lactoglobulin active antigen in the sample was detected.

Embodiment 2

[0027] (1) Preparation of cysteine solution: solid cysteine at 0.1mol L -1 Dissolve in HCl, after the dissolution is complete, use 0.05mol·L -1 NaOH was adjusted to pH 7.0, and sealed for storage until use.

[0028] (2) Add the cysteine solution prepared in step (1) to 0.15mmol·g -1 The amount of protein added to the whey protein solution, the concentration of whey protein is 30g L -1 , pH 7.0, and treated in a water bath at 37°C for 30 minutes.

[0029] (3) Add 3U·g to the sample treated in step (2) -1 1. Protein transglutaminase, react in a water bath at 37°C for 4 hours, inactivate the enzyme at 85°C for 10 minutes after the reaction, take it out and cool to room temperature. Using untreated raw whey protein as a control sample, the content of α-lactalbumin and β-lactoglobulin active antigen in the sample was detected.

Embodiment 3

[0031] (1) Preparation of cysteine solution: solid cysteine at 0.1mol L -1 Dissolve in HCl, after the dissolution is complete, use 0.05mol·L -1 NaOH was adjusted to pH 7.0, and sealed for storage until use.

[0032] (2) Add the cysteine solution prepared in step (1) to 0.15mmol·g -1 The amount of protein added to the whey protein solution, the concentration of whey protein is 30g L -1 , pH 7.0, and treated in a water bath at 37°C for 30 minutes.

[0033] (3) Add 5U·g to the sample treated in step (2) -1 For protein transglutaminase, react in a water bath at 37°C for 4 hours, inactivate the enzyme at 85°C for 10 minutes after the reaction, take it out and cool to room temperature. Using untreated raw whey protein as a control sample, the content of α-lactalbumin and β-lactoglobulin active antigen in the sample was detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com