Method for preparing hypoallergenic whey protein by coupling protease hydrolysis and transglutaminase cross-linking modification

A technology of transglutaminase and protease hydrolysis, applied in protein food processing, animal protein processing, protein food ingredients, etc., can solve problems such as lack of stable interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

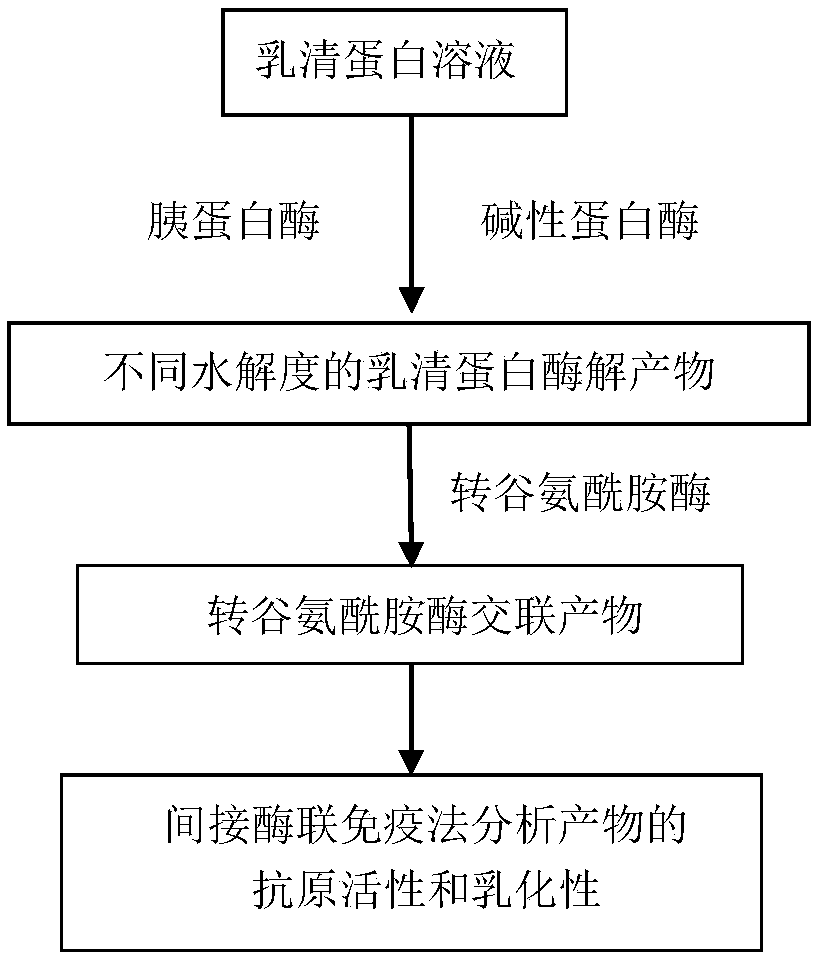

Method used

Image

Examples

Embodiment 1

[0022] (1) Prepare 3% (w / v) whey protein solution.

[0023] (2) Add alkaline protease to the whey protein solution prepared in step (1) to hydrolyze whey protein at pH 8.5 and 60°C. During the hydrolysis reaction, add 0.5mol NaOH to maintain the pH value of the reaction system , measure the degree of hydrolysis, draw the hydrolysis curve, and obtain a hydrolyzed sample with a degree of hydrolysis of 2.5%.

[0024] (3) Add trypsin to the whey protein solution prepared in step (1), and hydrolyze whey protein at pH 8.0 at 50°C. During the hydrolysis reaction, maintain the pH value of the reaction system by adding 0.5mol NaOH, and measure Degree of hydrolysis, drawing a hydrolysis curve, and obtaining a hydrolyzed sample with a degree of hydrolysis of 2.3%.

[0025] (4) Add 15U·g to the sample treated by step (2) and step (3) -1 For protein transglutaminase, react in a water bath at 37°C for 2 hours, inactivate the enzyme at 85°C for 10 minutes after the reaction, take it out an...

Embodiment 2

[0028] (1) Prepare 3% (w / v) whey protein solution.

[0029] (2) Add alkaline protease to the whey protein solution prepared in step (1) to hydrolyze whey protein at pH 8.5 and 60°C. During the hydrolysis reaction, add 0.5mol NaOH to maintain the pH value of the reaction system , measure the degree of hydrolysis, draw the hydrolysis curve, and obtain a hydrolyzed sample with a degree of hydrolysis of 2.5%.

[0030] (3) Add trypsin to the whey protein solution prepared in step (1), and hydrolyze whey protein at pH 8.0 at 50°C. During the hydrolysis reaction, maintain the pH value of the reaction system by adding 0.5mol NaOH, and measure Degree of hydrolysis, draw the hydrolysis curve, and obtain the hydrolyzed sample with the degree of hydrolysis of 2.3%.

[0031] (4) In the sample treated by step (2) and step (3), add 5U·g -1 For protein transglutaminase, react in a water bath at 37°C for 4 hours, inactivate the enzyme at 85°C for 10 minutes after the reaction, take it out an...

Embodiment 3

[0034] (1) Prepare 3% (w / v) whey protein solution.

[0035] (2) Add alkaline protease to the whey protein solution prepared in step (1) to hydrolyze whey protein at pH 8.5 and 60°C. During the hydrolysis reaction, add 0.5mol NaOH to maintain the pH value of the reaction system , measure the degree of hydrolysis, draw the hydrolysis curve, and obtain a hydrolyzed sample with a degree of hydrolysis of 8.1%.

[0036] (3) Add trypsin to the whey protein solution prepared in step (1), and hydrolyze whey protein at pH 8.0 at 50°C. During the hydrolysis reaction, maintain the pH value of the reaction system by adding 0.5mol NaOH, and measure Degree of hydrolysis, draw the hydrolysis curve, and obtain the hydrolyzed sample with the degree of hydrolysis of 7.9%.

[0037] (4) Add 10U·g to the sample treated by step (2) and step (3) -1 For protein transglutaminase, react in a water bath at 37°C for 4 hours, inactivate the enzyme at 85°C for 10 minutes after the reaction, take it out an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com